Forms for cooking cutlets: types and selection criteria

Various kitchen appliances are designed to facilitate the work of the hostess. They help to prepare delicious and beautiful food. For example, cutlet forms are a newfangled device with a lot of advantages. With its help, your cutlets will acquire an aesthetic appeal.

Peculiarities

The design principle for all cutlet frying presses is approximately the same. There are three elements in the form:

- top and bottom covers;

- the press itself.

The round parts are connected into a single structure and represent a complete kitchen device that allows you to speed up the cooking process. Minced meat is put in the lower part and one half of the cutlet is formed. The top lid allows for a neat filling. The third device is a manual press, which can be used to press down the minced meat and form a hamburger blank or a classic cutlet.

Some molds are equipped with a removable bottom, which allows you to remove the resulting product without any problems.

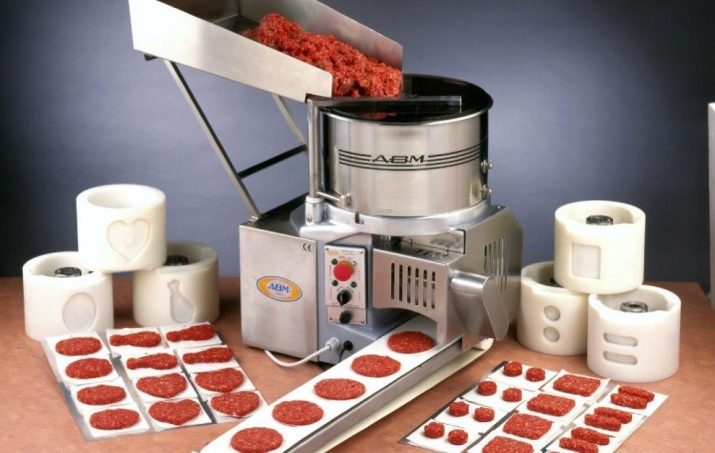

The cutlet itself, pressed in this shape, turns out to be round and flat. This type of food is called meatballs in cooking. It is believed that a billet thickness of up to 2 cm shortens the roasting time, retaining all the juice and aroma inside. Another type of round cutlets is steak. This product is also round and flat, and differs in the way it is cooked. At food enterprises, cutlets are molded on a special machine. She molds the blanks, breeds them, but only on one side. Semi-finished products are finished manually.

It is the ruddy crust on the outside and juicy minced meat inside that testifies to the correctness of the cooked cutlet.There are certain requirements for the shape of cutlets in catering technology. At home, there is no fundamental need to make oval-shaped blanks, considering them perfectly correct.

Advantages and disadvantages

Like any other household appliance, cutlet molds have their pros and cons.

- The press allows you to cook cutlets that are perfect in shape... For a layman doing kitchen work with his own hands, it is impossible to achieve perfect results. Different sizes of workpieces may burn during frying or remain soggy. The press will ensure the same cooking.

- The cooking speed is reduced due to the use of the mold. In this case, no special labor costs are required.

- The press assumes a wide range of possibilities of operation. The use of the form is limited only by the culinary skills and imagination of the hostess. Here it is allowed to choose various products for both the minced meat and the filling.

- The modern mold is easy to maintain. The structure is disassembled and easy to clean. The device is sold with detailed instructions.

- Compactness. The size of the mold allows it to be stored in a drawer with other kitchen accessories. The press does not require special storage conditions.

The manual device for the home is not without its drawbacks, among which is the low output capacity. Automated devices that are used in enterprises do not have this disadvantage. Users also note the negative characteristics of inexpensive Chinese products. For example, color dyes used in presses react with food. The quality of the material is low, so the forms quickly deteriorate. Silicone molds have a very unpleasant odor.

A quality certificate will help to exclude the possibility of acquiring a fake. Users are advised not to purchase too cheap forms. The low price often hides the danger to their own health.

Varieties and their purpose

Cutlet presses are divided into two main types:

- manual mold for modeling;

- automatic device.

The first option is suitable for home use, but if you do not need to cook a lot of stuffed cutlets. Hand-held presses are used in food service outlets, provided that there are few burger patties here, and they are not the main course of the menu. The principle of the devices is simple, but designs can be solid or separate. The first type is of better quality, and the second is easier to wash after use. Both devices are suitable for the formation of stuffed cutlets, which then only need to be placed in the pan for further cooking.

Molds can also be used for baking, for freezing, for stuffing various semi-finished products.

The second version of the forms is suitable if you need to cook a large number of portions. The species is widely used in various fast food establishments. A distinctive feature of the device is the presence of containers for making cutlets of various shapes. The diameter of the containers varies from 100 to 130 mm, while the press practically does not require human intervention. It is enough to press a button, add minced meat to the machine, and he will do all the work himself. The device is capable of producing from 200 to 300 hamburger blanks per hour. The main disadvantage of an automatic mold is its high price.

Molds can be single-layer, two-layer, three-layer. The latter, especially qualitatively, can reduce the cooking time, since they can contain several workpieces at once. Single forms need to be used for each cutlet separately, but they are very easy to use. You still need to learn how to use the previous option.

Double and triple shapes are not separable. Whereas a single analogue has a separate press and body. Some products are complemented with a grooved coating, which adds a grilled look to the patty.

Materials (edit)

Popular cutlet molds are metal, plastic. There are also silicone, but the demand for them is small.

- Metal has a longer service life, therefore it is more popular. If the form is made of high-quality stainless steel, then it will not absorb odors. The metal is considered waterproof and very durable. The main disadvantage of metal molds is their susceptibility to corrosion. Modern forms with a special coating eliminate this negative quality. The disadvantage of such products is the high price.

- Plastic molds are not inferior in popularity to the previous version. Responsible manufacturers create products with quality and strength characteristics that are sold at a lower price compared to metal molds. In addition, plastic does not rust, and the material's water resistance is the same as that of metal. Negative qualities: absorbs odors, not as strong as metal.

- Silicone molds for cutlets are not very common. The products are not of high quality. In addition, there are many fakes on the market, as manufacturers are trying to reduce the cost of the material by adding harmful components to it.

How to choose?

Recommendations for choosing cutlet molds relate to the rules for buying a quality product. There are far from safe presses on the market, so buying a form should be a responsible event. It is not worth spending money on the first cutlet mold that comes along.

It is especially worth considering the choice of plastic forms. The material must be of high quality, food grade, with special markings. The smell of plastic may be slightly present on a new product, but after the first cleaning with detergents, it should be completely removed. If signs of chemical aromas remain, then it is better not to use this form.

Quality plastic presses must be made by injection molding. Low-quality fakes will have burrs and other defects on the surface. They are noticeable upon close inspection of the product, therefore the options chosen must be carefully considered.

The design of the forms is different, but experts advise giving preference to separate elements. The process of forming cutlets in such devices is more convenient, and the press itself is easier to clean.

How to use?

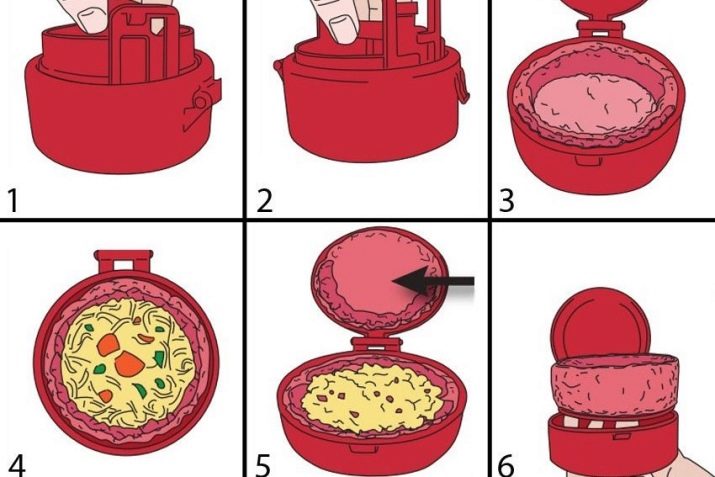

The manual cutlet mold is easy to use and will help simplify the cooking process for inexperienced housewives. Devices made of different materials look almost the same and are supplied with identical instructions. The document assumes the following step-by-step steps.

- To begin with, it is recommended to moisten all parts with cold water. This will prevent the minced meat from sticking to the surface.

- Put a portion of the minced meat in the bottom lid. Then the top is closed, and a press is needed to press down the product. With its help, you can form a recess for the filling.

- Then you need to open the form, and put any products in the groove: you can use boiled eggs, cheese, mushrooms, potatoes. It is desirable that the filling is not liquid.

- The other half of the minced meat is put into the top cover. The press closes, and all parts of the cutlet are squeezed into a single whole piece. It can be sent directly for baking or left for further freezing.

The operations are simple, they are repeated in the same way, they take a little time to complete. The cutlets are the same size, usually about 10-12 cm in diameter. These blanks are designed for use in hamburgers. Resizable molds have recently appeared on the market.

With such a device, you can make different cutlets, but at a cost it is more expensive than conventional molds.

For information on how to use the form for cooking cutlets, see the video below.