All about potato peelers

Knowing everything about potato peelers is important not only for professional chefs, because this technique has both an industrial and a domestic version. When choosing, you will have to study the features of abrasive discs for potato peelers and other components.

After the purchase, it is worth figuring out how to peel potatoes with an industrial peeler and household appliance.

What it is?

By itself, the word "potato peeler" is not entirely true. Although its main purpose is precisely to work with potatoes, it is more correct to assume that this is a machine for peeling root crops of all types. It also allows you to cope with fruit peeling. It is established that such devices were created in France in the late 1920s. But the result of the development of French engineers was quickly appreciated by specialists and consumers in other countries.

It was gradually discovered that the characteristics of elementary potato peelers did not meet the needs of large food industries. There, as well as in public catering, they began to use more advanced machines. In industrial systems, there are:

-

tank with reliable walls;

-

a cup of coarse emery;

-

trays or flaps for pouring ready-made vegetables.

Views

Manual and electric

The principle of operation of electric potato peelers is relatively simple. Above is a block that accepts tubers. There is a bowl under it. In the lowest chamber, the peeled tubers are shipped. Some devices are equipped with auxiliary knives, which improves the quality of cleaning. The procedure is performed by rotating the container.

Mechanical models work autonomously. Some of them are powered by batteries.The tubers are fixed with holders, and then, when the rotation begins, they are cleaned with thoroughly sharpened knives. But in most cases, the choice is made in favor of manual models. Outwardly, it is a handle made of sturdy plastic and metal, complemented by blades that perform the cleaning procedure itself.

Industrial and household

The production professional potato peeler is equipped with a large bowl. A special abrasive material is applied to the walls of this bowl. With its help, the peel is effectively removed. Root crops are loaded through the hole in the upper part of the chamber. The working chamber of the potato peeler for the dining room works when rotating; the camera should spin quickly.

Some versions of industrial cleaning devices allow rinsing root crops. They are simply connected to the water supply during installation. There is no need to manually fill in water. No wonder - unlike home appliances, washing each potato separately in canteens, restaurants and large manufacturing plants is impossible.

The difference between industrial and household equipment is not only in performance, but also in the weight of the device, in its size, in the total volume of the working chamber.

Chamber and continuous

The first type involves peeling potatoes with conical discs. It delivers excellent results. Continuous potato peelers use roller discs. Such a system cannot boast of special power and performance. However, in cafes, restaurants and other catering establishments, she will show herself from the best side.

The rollers are usually made of abrasive materials. They are set taking into account the diameter. In some cases, instead of tapered rollers, cylindrical rollers covered with flexible threads are used. The design is calculated in such a way that the contact between the potatoes and the rollers occurs over the largest possible area. The movement of fruits between sections goes through windows equipped with regulating dampers.

Table and floor

As you can easily understand, desktop models are predominantly placed on desktops. However, in some cases, they are mounted on special stand stands. Placing the motor above the implement reduces the space required. But in some cases, the engine is located under the working part. Floor-standing models are the most productive and always take up a lot of space.

By type of working tool

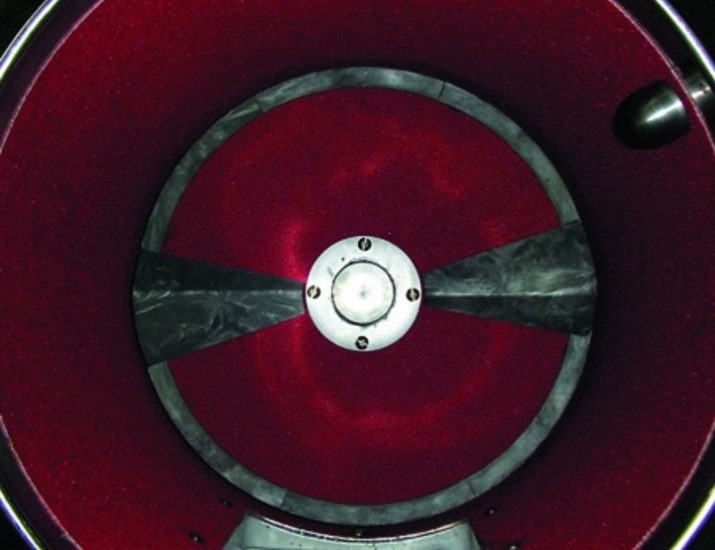

Potato peelers with conical working parts are gradually going out of circulation, they are released less and less frequently. Disc machines peel potatoes by rotating a metal disc. Their main working part is made from abrasives. The surface of the disk contains 2-4 waves, the height of which is greater at the edge than in the center.

Waves can be made separately and additionally mounted on the disc; their function blocks the simultaneous rotation of the processed products and working bodies.

Returning to cone machines, it should be emphasized that their working cone is of a truncated type. Its surface is invariably rough. The bottom has 3 ridges with a wavy structure. The wave is the higher, the closer it is to the conical segment of the working body. The bowl with abrasives is placed on the disc, after which it is held by the shell - this structure allows you to change worn surfaces.

Discs may differ in different cases depending on the purpose. So, a coarse-grained abrasive allows you to confidently cope with old root crops with a dense surface. For a fresh harvest of vegetables, fine-grained discs should be used. The brush models are suitable for peeling onions. The knife versions are good if you want to reduce the peeling of the skin, and the perforated discs successfully peel, in addition to potatoes, also beets and carrots.

Top best manufacturers

For home use, you can choose WEBBER BE-5288... It has 3 knives made of stainless steel. These knives are respectively:

-

remove the skin from soft fruits;

-

peel potatoes and other tough root crops;

-

cut vegetables in the manner of strips.

Swiss brand VICTORINOX also performs well. This company supplies products in different colors and with different levels of functionality. The basic construction material guarantees zero risk of slipping out of the hands. Victorinox cleaning tools help clean both soft and hard fruits. The knives have sharp blades and their handle does not slip in the hand.

JOSEPH TRI-PEELER is praised for its versatility. This potato peeler, again, has 3 working knives. When using each of them, the rest are hidden by the body. Therefore, the risk of injury will be zero. There is also a special device that helps to cope with eyes and other small defects.

FIRST AUSTRIA FA-5120 WHITE - potato peeler with drying option. It can work with a variety of root crops. The manufacturer insists that such a model is capable of squeezing lettuce leaves. You can put 1 kg of potatoes inside. Knives are designed for zero slip probability; there is a compartment for storing wires and a transparent cover for monitoring operation.

TRAMONTINA UTILITA - a model, the working part of which is made of steel AISI 420. But this alloy is subjected to a special multi-stage hardening, which allows to ensure a particularly high ductility. Along the way, high temperature resistance and corrosion resistance are achieved, without loss of strength. Thick steel and a particularly secure fit ensure a long service life of the product. The manufacturer insists on:

-

carefully peeling vegetables and soft fruits;

-

resistance to mechanical stress;

-

no risk of the handle slipping even in wet hands;

-

lack of absorption of foreign odors.

It works on the principle of a centrifuge model ARESA AR-1501... The grater inside the container is spinning. Tubers lose their peel under the action of friction. The working part will move at high speeds. Transparent plastic in the lid allows you to accurately control the quality of work; all other parts are made of opaque plastic, which ultimately guarantees a lightweight construction.

But it is not very reasonable to limit ourselves to household models in the review. Sammic PP-12 + is well suited for catering... This model is equipped with an electromechanical control system. First-class materials are used for the manufacture of the device. It serves for a very long time. You can put up to 12 kg of potatoes at the same time, and up to 270 kg of raw materials can be processed per hour.

Sirman PPJ 10 SC 1F is considered an alternative. The Italian car has excellent performance and is quite practical. Buyers mention that it is quite convenient. The system works when connected to a 220 V network. Such a potato peeler weighs 41 kg, and its size is 47x54x91 cm.

If you need to choose an apparatus capable of processing up to 300 kg of potatoes in 60 minutes, then it makes sense to opt for Gastrotop HLP-15... The device is appreciated for its easy flushing, and its dimensions are small. The delivery set includes a mash catcher. For 1 reception, up to 15 kg of potatoes are peeled.

Connection to the water supply for washing the potatoes is quite possible.

SAP PL20 can also be a good solution. This model is equipped with a polycarbonate lid. It is equipped with an electromechanical control system. During the cycle, up to 20 kg of root crops are cleaned. The device weighs only 45 kg and can be easily installed in small rooms.

Components

In addition to abrasive discs for potato peelers, the following are often used:

-

abrasive stone;

-

drive belt;

-

pulley;

-

loading vegetable cutting device;

-

special cover;

-

funnel;

-

piller-type knife (excellent for various vegetables);

-

side nets;

-

pressure sleeves;

-

shafts;

-

screws.

You may also need:

-

sucker;

-

unloading hatch;

-

bowl with abrasives;

-

knife lattices;

-

shredding and wiping discs;

-

shells;

-

seals for doors.

Secrets of choice

The key indicator is the performance of the potato peeler. For home use, for a cafe, you can limit yourself to a relatively low-power device. However, large enterprises in the food industry need high-performance equipment. It is equipped with always capacious, roomy cameras.

The country of production does not really matter: almost all enterprises produce quality goods.

The weight and dimensions of the peeler must also be taken into account. It depends on them where the device can be placed and how convenient it will be to transport it. The heaviest models are made in Russia and China. Italian potato peelers are lighter on average. Some devices are equipped with digital timers that allow you to set the required cleaning time.

Usage Tips

Before peeling potatoes with a professional peeler, you need to:

-

make sure that the case is well grounded;

-

test all key nodes for serviceability;

-

check if water enters the chamber (if a washing mode is provided).

To properly use a professional potato peeler, you must also check if its abrasive coating is in good condition. There must be no foreign objects inside the working chamber during start-up. The instruction also always insists on maintaining a good sanitary state of the equipment. When starting up for the first time or after a long break, you must first start the car at idle speed.

Only if the system creates a uniform sound, the operating rules allow it to be used in work.

Normally, about 1 liter of water is consumed per 1 kg of potatoes or other vegetables. It is very useful to sort the fruits by size and quality, wash them thoroughly in advance. This will help reduce waste generation. Sorting and washing is shown even for using manual potato peelers at home. Such procedures will allow you to work more efficiently and keep the devices working longer. It is unacceptable to put your hands close to the working parts or even immerse them in the working chamber; it makes no sense to try to sharpen knives, because it is much easier and easier to replace them.

When the machine is finished, you need:

-

de-energize it;

-

turn off the tap;

-

clean from product residues;

-

remove dirty water;

-

rinse everything with clean water to remove any dirt

-

disassemble and rinse the machine, while avoiding getting water on the buttons and the electric motor.