DIY sofa making methods

Homemade furniture is a source of pride, a chance to learn furniture business, craft. If you like to create, craft household items, then homemade furniture is not only your hobby and a means of self-realization, but also a weighty profitable article. If, of course, you quickly master the whole process and prove yourself at your best.

Features of homemade furniture

Homemade furniture has the following advantages.

- The ability to give the desired look, which has no analogues in any store of ready-made furniture items. Want the sides of your sofa to resemble a jelly pie with dough-filled sections of the pattern filled with filling? You can create the exact same relief by sawing and turning the plywood layers. In this case, the outer layer itself is painted with a colorless varnish - and the depressions formed by the second board lying under the first one are painted with dark brown or red-brown varnish.

- Using only natural wood. Don't like plywood? Buy a board - the right number of pieces of a certain length, width and thickness - and do as you please.

- The ability to use the highest quality components from old sofas, beds, armchairs. Are there only chipboard products in the store? The neighbors on the porch threw away the old furniture, which has solid boards, sheets of plywood? Or maybe someone threw out an old Soviet door with a jamb? Do you know how to assemble furniture for your own reasons, without even having a plan? Collect these pieces of wood, boards and make a sofa, bed, armchair-bed in a classic manner. And then finalize, create your own design.

- Want to excel? For example, do you know how to burn wood? Draw a picture with a soldering iron or a sunbeam in the summer, caught in the focus of a magnifying glass. And cover your "graffiti" with furniture varnish, painting the entire board on which you painted.

- Do-it-yourself furniture from available materials is several times cheaper than ready-made furniture. You can get an even bigger gap in price if you have a lot of used but well-preserved wood from old furniture. An alternative can be a cast wood-epoxy-plastic material - cast composite, from which moisture-resistant interior doors are made. If you come across a door that has served its purpose - subject to the integrity of the canvas, such material will also fit on a sofa or bed

- The most valuable thing is experience... Even making according to ready-made schemes and sketches, painted step by step, a completely “green” beginner will sooner or later learn to make masterpieces that are not inferior in quality to purchased luxury furniture.

The disadvantages are as follows.

- At first, a beginner will spend more time making furniture until he has perfected a series of actions to automatism.

- This activity is very labor-intensive and resource-intensive, it takes up a lot of personal time.

If a person has learned in this matter and decided to register as an individual entrepreneur in order to earn good money, then he will need to regularly deliver new materials and structural elements, keep his warehouse, work in a continuous stream of orders, sometimes update worn-out consumables for tools.

What can be made of?

A do-it-yourself sofa is made from the following elements and structures.

- From car seats. Seats are bought at the car market, in a specialized car hypermarket or a car shop at a service station. Rear seats from any passenger car will do - a prefabricated set where 3 or even 4 people can be accommodated in the back. Find out which car models are 6- and 7-seater, and buy a prefabricated seat for one of these car models. You can use seats for fixed-route taxis - brands "RAF", "GAZelle", "Ford" and other passenger vans. They are arranged in a row - the rear one has 4 seats. The main thing is that their sides do not bite into the person lying on them, and also lean back. In theory, any reclining seat will do.

- Made of wood. Any sofa design, dozens of variations will help you. But several types - "book", "corner", sofa, frame, frameless - are still there. Any frame is made of wood or chipboard.

- From metals and their alloys. Any aluminum or steel profile will do. If you are a fan of furniture with a purely metal frame, then even a thick (60 * 25 mm) reinforced eaves aluminum profile, stainless steel corners will do. However, thick steel (from 4 mm) in an angle, T-bar or P-profile, as well as in pipes, will lead to the fact that a sofa welded from ordinary steel pipes and profiles will weigh 300 or more kilograms. It will be possible to move it only with ten people, and to take out, transfer from a house or a building of a non-separable sofa, the help of at least 20 people will be required. Such a sofa will push through an ordinary floor over time, which is why the design is suitable only for a yard or a gazebo, and not for a house. Particularly distinguished units cooked sofas even from old rails taken from an abandoned railway track. As a result, such a structure weighed as much as "Moskvich-412" - a ton or more.

- Of two mattresses - except for inflatable ones. But mattresses do not hang in the air, and are also installed on a base - lattice with legs, box, sliding, folding, etc. In the simplest case, the base is a door leaf, to which, instead of a jamb / platband, a second one is screwed on hinges. The folding legs (hinged with a catch) are screwed to both doors, which serve as sofa doors.Additional spring-latch mechanisms are installed at the ends, which do not allow the sofa to open - if it is not against the wall, but in the middle of the room. If the doors are sold only complete with door frames, then the parts of the latter go to the sofa legs, beams, etc.

- From rattan. This is a woven texture from stripes. It resembles a fabric texture increased 200 times, in which the threads are woven in the same way - perpendicularly. They alternately go over each other. The strips can be cloth, plastic, rubber, etc. Rattan can be woven from anything - cut into strips of linoleum, coils of electrical wire (or removed the protective sheath of old cables), twine, rope or even a thin rope. Rattan is an alternative to upholstery. This is how baskets, hats, etc., were previously woven from plant branches.

- From car tires... Car tires are the base on which planks or padded upholstery is laid to form the flooring of the seat and backrest. Passenger car tires are not rigid enough. Here you need tires from a truck, tractor or special equipment (truck crane, bulldozer, rear wheels of a tractor, etc.). This option is perfect for a garage or loft living room.

Having decided what you will make the sofa from, find a diagram showing how your product will come to life.

Manufacturing schemes

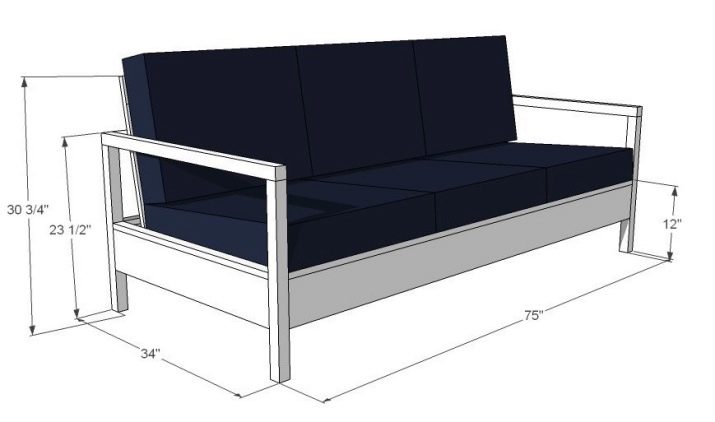

Any drawing of a do-it-yourself sofa immediately informs about the type of construction.

It can be U-shaped, modular, in the form of a sofa bed (folding), in the style of a bay window (parallelepiped or polyhedron) or semicircular. The latter includes, for example, the construction of car tires, where the sidewalls are made of their halves.

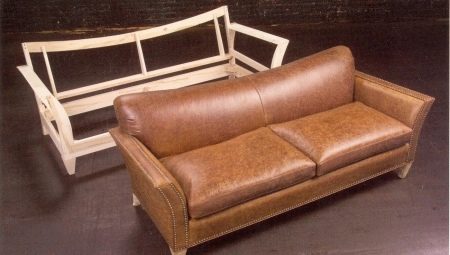

Wireframe

To make a frame sofa at home, you need the following materials: wide boards, bars, slats, self-tapping screws, epoxy (or carpentry) glue, dowels, putty and sofa cushions (or sofa). From tools - a miter saw, an electric drill, a grinder with a set of grinding discs, a screwdriver, a pair of drills for dowels and screws, clamps of various sizes, a jig for corner drilling, a spatula, smooth cloth, square, pencil, tape measure.

To prepare the elements of the sofa, do the following.

- Divide the boards into sections of the desired length. So, you need 6 segments for defining the dimensions of the base of the sofa with shelves.

- From the beams, make pieces of the lamellar base. You need two sets - one for the seat and one for the back.

- Sand all parts with a 220 grit disc.

For staining with stain, all external parts, their sides must be especially smooth. To assemble the structural frame, do the following.

- Use a tongue-and-groove method of joining parts... Using a jig, drill the holes at the desired angle. For dowels, select the correct drill and make sure that the dowel with some effort goes into the groove.

- Fasten the parts of the supporting base to the shelves using self-tapping screws and glue. Do not remove the retaining clamps from the structure before the epoxy is dry and cured.

- Insert the top structure into the base with dowels.

- Combine all the resulting parts of the structure on a flat floor and attach them to each other with glue and self-tapping screws.

After the epoxy has hardened, start filling the structure.

- Fill the holes left after screwing in the screws.

- After the putty has dried, sand the areas where it has hardened.

After leveling, apply a special oil that protects the wood from moisture with a brush.

Proceed as follows to make a bearing support for the lamellas.

- Fix all parts with temporary joining using board trimmings.

- Secure the slats to the base, positioning them so that they enter when the sofa slides into each other.

- Fix the narrow board together with the lamellas using the same epoxy.

To make a sliding structure, do the following.

- For a while, fix the wide frontal board with three stops.

- Put the frame on these stops so that the same board is immobilized for the duration of further actions.

- Attach the rest of the lamellas so that there is a small gap between them.

- Check how the drawer slides in and out. To make it easier, screw the rollers in the moving places - it will be easier to move the sofa apart.

Once you've finished assembling the main parts, arrange the sofa and pillows. The sofa is practically assembled.

Frameless

You need: foam rubber and a coarse, dense fabric for upholstery, glue, threads and needles, chalk, zippers and flock. Tools - a sewing machine and scissors. Please do the following.

- Cut out pieces of foam rubber 160 * 90 * 4 cm under the base, 160 * 60 * 4 cm under the seat.

- Also cut out parts: 160 * 30 * 4 and 160 * 50 * 4 under the back.

- For pillows, cut 6 sheets of foam rubber - the pillows will take on a height of half a meter. Glue the foam layers together and sew them over with a lining material.

- Sew the flock upholstery by cutting the fabric under the pillows.

- Place a zip lock on one side of each pillow.

- Assemble the sofa. The frameless model is ready.

Corner with retractable mechanism

A pull-out corner sofa allows you to place additional storage inside - under the seat. Of the tools for its manufacture, you will need: a jigsaw, a grinder with a set of sanding discs, an electric drill, a furniture stapler, a sewing machine, a screwdriver, plywood or a board with a thickness of at least 12 mm, wooden blocks with a cut of 50 * 30, 5 mm plywood, fiberboard sheets, fabric for upholstery, self-tapping screws, epoxy glue, furniture corners made of steel, foam rubber or felt, spring block, ready-made sofa legs.

For crafting, do the following.

- Cut the necessary parts and connect them with corners on self-tapping screws.

- Cover the bottom of the structure with plywood or fiberboard.

- Also close the top of the box with plywood and hinges.

- Assemble the backrest and attach it to the front structure.

- Attach a sheet of fiberboard at the back to cover the insides of the back. Use a stapler to pull the fabric over it.

- Glue or staple a layer of foam rubber.

- Install the spring block on the seat, cover it with foam rubber.

Cover the seat with an outer fabric cover to cover the inside of the seat. Now you can make and install boxes under the seat by attaching handles to them.

The corner sofa with drawers is assembled.

Sofa-book

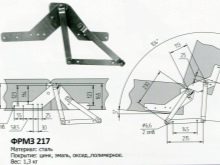

In addition to wood planks and plywood, buy transforming fixtures.

- Saw the boards and plywood into the desired elements and connect them using epoxy and self-tapping screws. Wait for all structures to gain strength.

- The result is a set: seat, backrest, drawers, armrests. Start assembling the sofa from the seat. Install "transformers".

- Place the backrest and the drawers.

Perform upholstery work - install the foam and wash the fabric.

Decorating

Begin installing the upholstery with foam rubber. Glue the foam strips to the armrests, backrest and seat. Use a fabric that is resistant to abrasion and wear so that it does not fray in a short time, such as a year. Choose a fabric that is easy to clean and clean if accidentally dirty. A sofa that can get splashed, for example, fly into a gazebo in oblique rain, it is useful to protect a water-repellent fabric with an impermeable impregnation - like the one used on waterproof jeans and windbreakers.

If the sofa is in a place where there is direct sunlight, the matter should not fade, crumble from ultraviolet radiation over time.

Pay special attention to the color scheme: it should be in harmony with the design of the room in which this sofa will be installed.

Correctly assembled and decorated with high-quality upholstery, the sofa will organically fit into the interior of any room. It can be installed both in the living room and in any of the bedrooms.Paying special attention to its manufacture, approaching its creation with all care, you will receive a piece of furniture that will be proud not only for you, but also for your children and grandchildren.

A master class on making a sofa (in 2 parts) can be found in the video below.