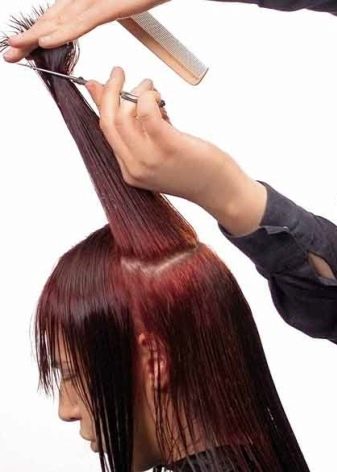

Hairdressing scissors: varieties and tips for choosing

Hairdressing scissors are the main tool of any haircutter. The quality and ergonomics of hairdressing tools are largely reflected in the final result of the work and on the client's image.

Peculiarities

Cutting tools for hairdressers differ from household tools in the material of manufacture, structurally and in shape.

For the production of scissors, high-quality steel is used, capable of maintaining the degree and proper sharpening angle for a long time. In this case, two types of sharpening are used - with a convection angle (38 °) and a right angle (up to 50 °).

Professional tools for performing haircuts are equipped with a special screw group - a system of special clamping elements that ensure the smooth running of the cutting elements. In the arsenal of a professional, products with special micro-notches are used to keep the curls from sliding off the surface of the blades. Various shapes of handles and rings, which make the tool convenient for long-term work.

Views

In the arsenal of an experienced craftsman, as a rule, there are at least 3 types of hairdressing scissors:

- straight, directly used for regular haircuts, including for curly hair;

- thinning;

- hot.

Various types of tool shapes are also used:

- classic;

- displaced;

- asymmetrical.

Classic professional tools assume the symmetry of the arrangement of both rings and blades of the same length. The shape is convenient for craftsmen with thin fingers, adherents of the classic style.

Displaced shapes allow you to remove unnecessary stress and reduce the level of friction.

Asymmetrical shapes rings relieve stress, but they are not suitable for everyone.For the most part, they allow you to choose a model that best suits the individual anatomical features of the structure of the master's hand. Therefore, they require fitting.

The variety of shapes and angles of displacement is in favor of the ergonomics of the product and is aimed at increasing the comfort of using hairdressing tools. In the same sense, additional insert rings and stops for the little finger are used.

Thinning

The purpose of the thinning scissors is thinning and shading hair. The tools are equipped with teeth in one or two blades. Often, young professionals choose double-sided products, since in the process of work, the degree of risk of removing more hair than is required is reduced. Nevertheless, one-sided models have a lighter stroke, which makes it possible to perform a haircut with less stress on the hair.

Hot

Hot scissors - products with a built-in heating element up to 90 degrees, which when cutting, it allows you to avoid structural defects in the hair, their split.

For slicing

To obtain high-quality slicing slices, you need a device with sharp edges. A suitable option for this would be products with convection sharpening. The blades of these scissors are convex, and the thickness of the sharpened edge is comparable to the diameter of the hair.

Slicing tool blades are generally straight or curved.

For sliding cut

Sliding cut products are generally manufactured in Japan. A special type of sharpening of the cloths ensures shaving of the hair. The canvases used to make such cuts are polished, and their inner side is sharpened using special technologies. The cutting surface is quite wide, the blades are arched.

Left-handed

Non-standard use of a non-dominant hand leads to early fatigue of the hands, and hence to a decrease in the level of performance. That's why most well-known brands produce devices for left-handed craftsmen, the difference between which is the position of the blades - the left is above the right, and the thumb notch is at the bottom.

Manufacturers

Manufacturers from Japan are the undisputed leader in quality and consumer properties of hairdressing devices. Japanese products, although expensive, have excellent performance due to the use of high quality steel, combined with high technology and a deep tradition of handcrafted cutting tools.

When processing blanks, the most precise robotics and computerized mechanisms are used. But the finishing of products is mainly done by hand. This approach has a significant impact on the brand ranking and allows us to produce the best products.

Let's note a few Japanese and not only companies that produce high-quality professional hairdressing tools.

- Tayo. The company's products are used in the most famous salons around the world. The assortment is represented by several collections, from classic to premium models. Prices - from 4000 rubles.

- Hinshitsu, Mizuka. Produce high quality premium products

- Kedake. Represents Japanese quality at budget prices. An excellent working tool with micro-bearings that allow smooth operation of the mechanism and extend its service life. The company has been on the market for about 10 years. The cost of the instruments is $ 65-297. A significant difference from other brands is the favorable ratio of well-known parameters in terms of design and ergonomics, as well as prices and quality levels. Kedake products are made from 440-C steel. Micro bearings have been used in products since 2004.

- Mizutani. A brand whose motto is "Functionality, quality and beauty". Products fully justify it.

- Joewell. Guaranteed Japanese quality at very affordable prices. The tool is used by both beginners and experienced professionals. Manufactured at the Tokosha factory.

- Dewal. A Russian-German brand that produces excellent products at affordable prices. Emphasis is placed on ergonomics and design. Prices - from 2300 rubles.

- Zinger. A well-known German brand that constantly monitors the quality of its products and the nuances of their assembly.

- Jaguar. Products from this brand stand out for their high German quality. The firm offers decent warranty periods. The scissors are characterized by strict ergonomic and design solutions. The devices are wear-resistant and unpretentious in maintenance. Prices - from 5000 rubles. Products do not need frequent sharpening, since special high manufacturing technologies provide the necessary sharpness and strength of the scissors for a long time.

- Suntachi. A South Korean brand that manufactures products from Japanese high-quality steel. The scissors are distinguished by high-precision manual sharpening and a unique screw mechanism.

- Mertz. Inexpensive German-made models with plastic handles. Their cost starts from 100 rubles, high-quality options - from 1000 rubles.

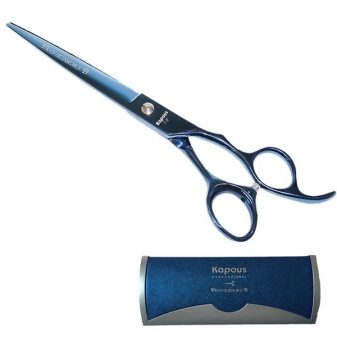

- Kapous. The Russian brand, on the market for 10 years, produces high-quality toolkits.

- Mustang. Produces a special line of Mustang Base scissors from a domestic firm. They are convenient and practical for both beginners and experienced craftsmen. This series uses quality X12 steel, which has decent hardness, which sharpens confidently and remains sharp for a long time.

According to the Salonoff rating, certain groups of goods from firms are in special demand:

- Mizutani;

- Hinshitsu;

- Supreme;

- Suntachi;

- Kedake;

- Dewal;

- Mertz;

- Kapous;

- PNG.

How to choose?

When choosing a hairdressing tool, it is important to consider a number of criteria.

- Before choosing a product, it is important to clearly understand for which haircuts it is purchased. So, scissors with small notches on the canvases are used for men's haircuts. They prevent the hair from slipping. Smooth, non-notched canvases contribute to a sliding cut, which is more often used in women's haircuts.

- The material affects the service life and the quality preservation of the original sharpening. The metal used for hairdressing tools is high carbon steel. To impart the best strength parameters to the product, alloys with the addition of molybdenum, tungsten, vanadium are used.

Nickel and chromium additives make the devices resistant to wear and corrosion.

- Correct sharpening - a guarantee of productive and competent work. It is worth paying attention to the sharpening angle, which must be maintained from 38 to 50 degrees.

- An important parameter is the shape of the scissors and the dimensions of the cutting ends along the length.... Experienced craftsmen divide straight, surgical, saber-shaped, ergonomic models, choosing the length of the blades depending on the specifics of the haircut. For many common and simple cuts, models with 5-5.5 "blades are suitable.

When performing men's haircuts and shading, long canvases are used, and scissors with short blades are useful for detailing.

- The width of the fabric is different. The wide ones are more suitable for sliding cuts, and the narrow ones for shading and precise cuts.

- Comfort of use should ensure long-term operation without fatigue of fingers and hands.

- The smooth movement of the canvases allows you to avoid defects in the hairstyle.

- A number of products provide for the presence of rubber pads in the rings, which are conveniently adapted to thin fingers, which contributes to overall comfort in work.

- It is important to pay attention to the special finger rests. This device greatly facilitates work and reduces hand fatigue. Trying on the stop will not be superfluous. In a number of models, the stops are installed in removable versions.

- Professional high quality products are expensive. Not too expensive models will suit beginners.

- The size of the teeth for thinning scissors is different.Thin and not very thick hair is cut with scissors with fine teeth, and thick curls - with thick teeth. It is better for the craftsman to have both options.

- Left-handed people should choose products for left-handed people. The difference is that the left canvas is positioned below the right, and the thumb rest is below. This greatly facilitates the work of the wizard.

- Check the tightening condition of the screw. To check, you should:

- take the product by one ring and direct the corresponding blade up;

- take the second ring with the other hand and take it vertically up, almost 90 degrees;

- release the second ring, under its weight the blades will close, and the degree of their closure will show the desired value. The distance between the clamping screw group of the product and the point of free closing of the canvases should be exactly half of their length.

When choosing a product according to the material of manufacture, it is important to consider the type of steel marking. The best tool has a hardness index of 58-62 HRC. With an increase in the index, the working properties of the product improve, but at the same time the fragility of the product also increases.

Chromium and titanium plated appliances are used for customers who are allergic to nickel-containing products. Gilding gives the product only elegance and does not have any other functions.

When talking about a screw group, it is important to consider that there are 3 types of screws used.

- Individual adjustment screws are flat. Such a screw is made without convex parts, so it does not interfere with the freedom of movement of the blades. Allows you to customize the degree of blade travel. You can use a coin to adjust.

- Universal screws for fine adjustment (protrude slightly above the blades). Allows you to manually adjust the smoothness of the blade, without equipment. Adjustment is ensured by the free running of the screw within certain limits. They have a locking and tensioning function that prevents it from wobbling.

- Lubricated micro bearing device, for which a special polymer is used, provides the required degree of slip during operation. The system facilitates the work process and effectively supports the mechanism without proper maintenance for a long time.

No matter how perfect the product is, it may require a special individual correction for the features of the specialist's hand. Therefore, it is worth immediately choosing scissors that provide for an easy adjustment of the stroke parameters and the speed of closing and opening of the blades. For this, special plastic rings are used to prevent fingers from slipping and make it possible to change the size of the rings.

Professionals are encouraged to purchase expensive handcrafted items. As a rule, they are more perfect at work.

It is better to buy tools in specialized retail outlets. You should first study all the documents for the goods. Often, under the guise of products of a popular brand, cheap oriental replicas are sold, which are of poor quality and have a short service life. If the price is significantly less than the branded one, then it is quite possible that you have a fake in front of you.

Care Tips

A professional tool is a complex mechanism that is influenced by many factors. Therefore, caring for the scissors is very important, it will ensure a long service life.

- Mechanical impact and shock should be avoided. Having dropped the product, you do not need to continue to work with it - it can be disabled, and the resulting defect will not be easy to fix. It is better to immediately contact a specialist who will carefully check and correct everything. In most cases, service centers are able to provide the necessary assistance.

- Regularly check the pressure of the blades. Too pressed blades not only complicate the work, but also, due to increased friction, lead to the development of mating surfaces.A similar effect appears when the clamping screws are loosened, when an unwanted backlash is formed between the blades. In this case, the clamping group fails, and with an apparent soft stroke, there is no possibility of making a correct cut.

- Hold the instrument correctly - means to use it correctly and to cut it with dignity. For a correct grip, you should:

- insert the ring finger into the lower ring;

- cover the instrument with a full palm;

- the thumb should rest against the ring, and the tool should be in a relaxed palm.

With this classic grip, the job begins and ends. In practice, there are many ways to grip, they depend on the client's haircut and the experience of the master. Some craftsmen get used to holding the scissors not quite correctly, using their individual techniques. If this does not affect the quality of the work, then various nuances are permissible.

At the end of the work, you should close the canvases and place the tool in the case., on a stand or just on a soft cloth. This is an extremely urgent moment. It is important to close the scissors at the onset of any breaks, and they should be placed on a flat surface covered with a soft cloth, preferably suede.

If a long break in work is expected, wipe the tool with a soft material and lubricate. Otherwise, the canvases may become covered with rust spots. There is no metal that would fully resist oxidation processes. The scissors must always be kept clean and lubricated.

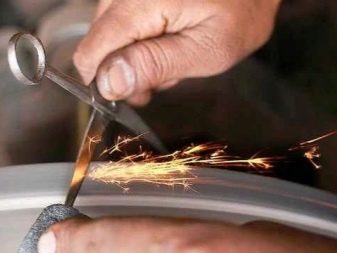

You should not sharpen the products yourself or give them for this to pseudo-masters who come to the salon and offer their services. This risk usually leads to disastrous results. It is important to understand that other types of scissors cannot be compared with professional hairdressing tools.

The screw groups available in your scissors should not be disassembled yourself. This is an occupation for specialists. Here, any spring or spacer plays a role in the operation of the mechanism. Even minor damage can negatively affect work results.

It is important to regularly check the sharpness of the cutting edges. At least once every 2 weeks, it is necessary to test the sharpness of the instrument with a piece of cotton wool, slowly cutting it. If the cotton wool is easy to cut, and the tips of the tool do not pull the villi, then the scissors are normal. Otherwise, contact special service centers where the sharpening of tools is carried out on special machines.

You should not bring the tool to its complete unusability. With careful and regular maintenance, it will last a long time.

It is important to know that sterilization of devices cleans them from microflora and dangerous hepatitis and HIV viruses... Disinfection of instruments does not kill all infectious agents, but only reduces the number of microbes on products, significantly reducing the risk of infection. By law, every salon is obliged to disinfect and sterilize instruments.

How to choose hairdressing scissors, see below.