Jaguar Mini sewing machine: features, model overview and operation

There are many types of home sewing equipment. But even against the general background, the Jaguar Mini sewing machine stands out for its quality. Therefore, it is necessary to carefully deal with such a technique and choose it correctly in order to get the best possible result.

The lineup

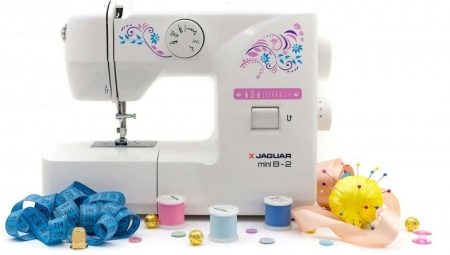

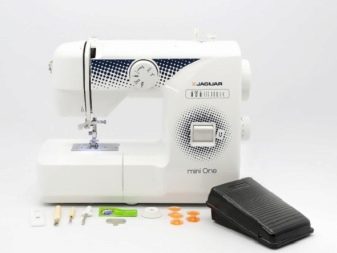

At the moment, this series is represented by only two modifications. And the first among them is Jaguar Mini One. It is capable of performing up to 9 work steps. The hinges are made according to the semiautomatic scheme. The brand warranty is given for 1 year. The manufacturer claims that such a model at the same time:

- compact;

- productive;

- very reliable even in adverse conditions;

- equipped with the proven metal shuttle.

The design is calculated for all the main tasks of sewing fabrics and materials of various types. The brand description states that the machine produces a clean and neat stitch. An automated needle threader assists in threading. Information labels on the device case will also be reliable helpers. Among the most important features are:

- smooth change in stitch length (up to 0.5 cm);

- the ability to adjust the tension of the upper thread;

- zigzag width up to 0.4 cm;

- retractable sleeve platform;

- high brightness LED lighting;

- comparative lightness (only 5 kg);

- motor power 35 W.

A typical delivery set includes:

- pre-installed universal foot;

- foot pedal;

- set of needles;

- ripping tool;

- oil reservoir;

- foot for a semi-automatic buttonhole;

- a pair of screwdrivers;

- case.

An alternative is the U-2 sewing machine. It is an electromechanical semi-automatic device with a one-year quality guarantee.The machine can carry out the same 9 basic operations and sew stitches with an adjustable (within 0.4 cm) length. The zigzag width is 0.5 cm. Provided:

- removable platform for working with sleeves;

- 35 W electric motor;

- powerful LED backlight;

- weight 5 kg.

How to lubricate?

Sewing machines, with proper care, can last for years or even decades. The easiest way to find the information you need is in the technical documentation for a specific product. But if it is lost or not too accurate, it doesn't matter - the problem is easily solved. It is very important to immediately write down separately which oil to use and how often to use it. If no information is available, it remains to use only regular machine oil.

Important: you cannot use containers and accessories that were previously used for any other tasks for lubrication. In the process of work you will need:

- suitable lubricating fluid;

- lint-free napkin;

- syringe;

- brush;

- tweezers;

- old kitchen oilcloth;

- screwdriver.

It is very good if at least some of these devices and tools are included. But when you need to buy them yourself, you need to go to a specialized store or to a department of a large supermarket.

The key elements that need to be lubricated are the shuttle and the parts around it. The machine is de-energized and placed on an oilcloth. Next, using a screwdriver, unscrew the screws that interfere with the removal of the case. When it is dismantled, it is time to use a brush to remove dust and dirt, accumulated fibers from different places.

Only then the mechanism is lubricated with oil using a syringe.

Some people apply it directly from a dispenser bottle, but the distribution accuracy and processing efficiency will then be lower. It is worth remembering to bring the tip as close to the part as possible, and then release a few drops of oil. You cannot use too much lubricant, because it is no less harmful than a lack of it.

Before lubrication, be sure to clean:

- shuttle;

- compartment where the shuttle is located;

- shuttle movement mechanism;

- spool cap.

It is worth walking with a brush even where there seems to be no dirt. Just a few invisible, almost particles of dust are enough to spoil the quality of the lubricant. In manual typewriters, it is traditionally advised to add the rotating parts of the handle. In the foot - the movable elements of the pedal.

After installing the case back it is necessary to immediately assess whether everything is correctly delivered and whether it is well fixed... The test is very simple: several test lines are sewn in idle mode. This will properly distribute the lubricant and get rid of excess in some places.

New sewing machines are lubricated every 6 months. Starting from the 3rd year of operation, this must be done every 3 months. But you also need to focus on emerging noises, on difficulties in work; sometimes both forces the use of the lubricant before the deadline.

Other usage details

DEven if your Jaguar sewing machine is well oiled, it still needs to be properly set up. The first step is to screw on the spring to press down on the thread. At the same time, make sure that the cap prevents the spool from untwisting. Rather, it can unwind, but only with a sharp pull up. The next step is to pass the upper thread through the feeding system.

It is very important to make the right decision every time exactly how to pull the thread. The machine will sew smoothly and beautifully only when the threads are intertwined. Their tension can only be adjusted with a special mechanism (top) and a shuttle adjusting screw (bottom). Dangling loops will be eliminated by pulling up or loosening the top adjuster.

Important: lumps that are not visible to the eye are found when the seam is felt; if they are not there, then the setting is completely correct.

The adjustment of the presser foot pressure in the latest models is automatic. But sometimes it is necessary to use manual adjustment. For sewing on thick fabrics, raise the foot as high as possible.If the seam does not go well, check to see if the foot is too loose. Additionally, you will have to adjust the needle piercing force and sewing speed.

The more difficult the manipulation, the slower the machine must run. To affect the length of the stitches, loosen the nut on the handle. After the lever has been moved, its handle is again fixed with a nut. When planning to bartack, the lever is lowered below the zero position and reverse stitching is performed.

But there are other relevant points in the instruction manual. It prescribes to disconnect the device from the network during a long pause in work. When the break occurs automatically due to the thread hitting the shuttle, the pause will take 20-30 seconds. You can resume work in 3 minutes. To do this, press the switch again.

You can remove the drawer for accessories by sliding it to the left. When it returns to its place, the table is moved in the opposite direction, achieving the entry of the pins into the holes. Open the box by pushing the lid up and back. The Jaguar Mini sewing machine contains many plastic parts.

Under heavy loads, they can be deformed, and therefore it is necessary to protect the system as much as possible, to avoid excessively frequent work with thick materials.

See the video for the analysis and principle of operation of the Jaguar Mini sewing machine.