All about induction tattoo machines

In 1891, 20 days after the creation of the rotary machine, a patent was filed for an induction device. Its creator was Thomas Riley, a London tattoo artist. The new invention was based not on an electric motor, but on the use of several magnetic coils invented by London scientists Alfred and Charles South.

Peculiarities

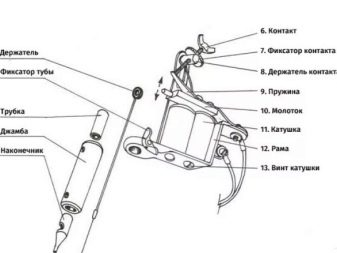

The principle of operation and structure are quite simple. The induction tattoo machine is powered by a magnetic field. The field is generated in turn by two small coils of wires. A drum (anchor) is located between the coils, the working surface bounces off the magnet of one coil and is attracted to the other coil. The vibration of this striker is transmitted to the spring and tip, and the vibration of the tip is transmitted to the needle.

A magnetic field is generated by an electrical current applied to the device from a power source through a wire called a clip cord. The strength of the electric field, and therefore the amplitude of the needle stroke, depends on the following points:

- power supply capacity;

- the number of turns of wire in the coil (the more there are, the more power);

- unit settings;

- installation of the tension screw.

Advantages

Let's take a look at the main advantages of an induction tattoo machine.

- It consists of a minimum number of components, which translates into low production costs.... Such machines are much cheaper than complex rotary products.

- The induction method is very effective for contouring. The thing is that the needle of this machine stays under the skin a little longer than the rotor. During these microseconds, the color pigment is well distributed at the injection site, eliminating the need for re-contouring.

- The fast contouring process reduces stress on the skin. In most cases, it will not cause irritation or severe inflammation, so you can complete your drawing in a couple of approaches rather than a few weeks.

- Induction machines very effective when tattooing problem skin.

- The induction machine is suitable for painting a large area of the skin. There are also special variants of machines (shaders) designed for this type of work. They are characterized by low power consumption.

- Device can adjust the vibration amplitude and force of the needle impact.

- If necessary you can increase the performance of the machine, replacing some components or changing the number of turns of wire in the coil. This upgrade is quite cheap.

disadvantages

This device also has disadvantages.

- Induction tattoo machines weigh tens to hundreds of grams more than rotary competitors. This puts more stress on the tattoo artist's arms and makes them tire faster. Therefore, this product is not suitable for beginners or women with small hands.

- This device generates an unpleasant loud crackling sound., which also increases fatigue while working.

- Due to the strong impact moment, higher vibration level. This can cause fatigue and make it impossible to work with particularly complex and small parts. In this case, only the rotor will save.

- For efficient work with various types of drawings (outlines and hatches) you must purchase two matching instruments at the same time.

Please note: Incorrect setting of the shock torque can result in severe skin damage. This feature is also considered a disadvantage of induction.

Varieties

There are two types of induction machines.

Liner

It can be used to create a clear outline. The dye is injected under the skin as quickly as possible to prevent it from spreading.

Consider the distinctive features of the liner:

- it is lightweight and has excellent ergonomics;

- the needle drop frequency is in the range from 120 to 150 Hz;

- the number of turns of the coil is minimal;

- the use of a rigid contact spring ensures quick penetration and repulsion of the needle;

- the greatest distance between the spring and the striker is 5 mm.

Important: her liner is suitable for shading the skin, as it leaves dots.

Shader

The shader is used to quickly apply patterns and shade large areas of the skin... It is designed to penetrate deeply into the skin and stay on the needle for a long time. As a result, the pigment spreads and forms a uniform pattern without dots.

Let's consider the distinctive features of the shader:

- This is a heavy machine - the severity is due to the use of powerful capacitors and coils with many turns;

- the frequency range of dropping the needle is from 60 to 100 Hz;

- the greatest distance between the spring and the striker - 10 mm;

- delivers less discomfort.

This machine is not at all suitable for creating contours, as the line becomes bold and shapeless.

Popular brands

Let's take a look at the best induction tattoo machines.

Vlad Blad Realistic Shader Respect

The leader in this area is undoubtedly the model of the Japanese brand, which is appreciated by both domestic and foreign craftsmen. Powerful features let you customize them optimally according to your needs. This model is used to create realistic images with smooth shadows and smooth transitions.... The device is designed to use up to 35 needles per seam.

The aircraft-grade aluminum frame is particularly strong and lightweight. Even beginners will have no problem using it thanks to clear instructions for setup and operation. The likelihood of injury is almost impossible. Thanks to the numerous functions, even small designs can be applied without errors.

Moskit Steel Solo Liner

In second place is a tattoo machine that makes you fall in love at a glance. Its design attracts every artist. The device is made using innovative technology that takes into account all the needs of tattooists: using needles from 1 to 11RL, you can create clear and smooth lines in one pass.

The frame is solid, made of steel. The product weighs 170 grams, which does not cause inconvenience even for long sessions. The machine allows you to create thin contours. A sharp lash helps prevent blur and other inaccuracies. This model is set to work for a long time, so neither the tattoo artist nor the client will feel discomfort.

Prime Coil Machine Shader

The third place was taken by a high-class car from the American brand Friction. It is handcrafted with durable parts and boasts a good design. Its high power allows it to work over a large area. Silver contacts are used to ensure reliability. The body is made of powder-coated cast steel.

This machine is used professional tattoo artists... There are no complaints about the product. It is perfect for shading. The transitions are smooth and realistic. Every detail is thought out to the smallest detail.

The artisans claim that the pigment spreads quickly under the skin, creating a uniform color field, which makes it easy to create a large image.

How to build and configure?

There is nothing difficult about assembling and connecting the tattoo machine. Let's consider a step-by-step diagram.

- Take the holder, insert the back tube into it, and then insert the tip. Both elements are now firmly in place.

- Next, the needle is inserted into the assembled holder.

- Attach the nipple to the bar leading to the striker.

- Insert the assembled holder into the hole of the tattoo machine and secure it with the tension screw. Do not overtighten the screw so that it does not interfere with the needle adjustment.

- The needle bar is attached to the frame with a rubber band to reduce unwanted vibration.

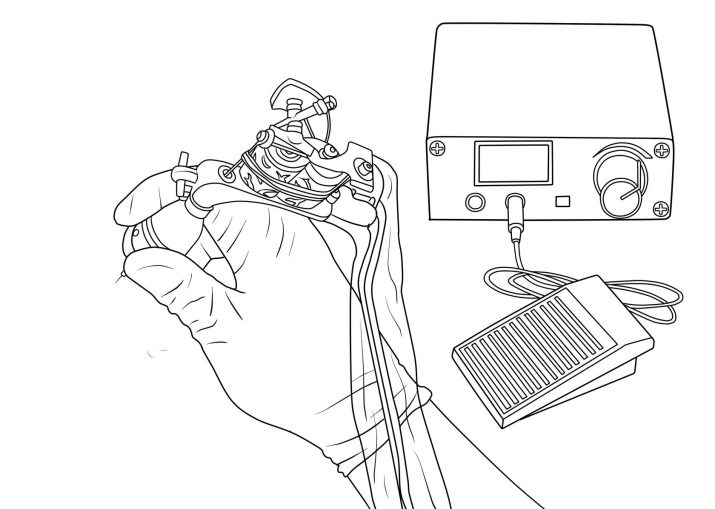

- Place a disposable bag over the clip cord.

- Turn on the machine, step on the pedal and try to reproduce the sound while working. Turn the screw until you get the desired needle stickout.

- Then connect the device to a power source and try to turn it on, adjust the hertzon and then adjust the tension screw so that the sound is clear during operation.

Operations can be performed to replace capacitors and increase or decrease the number of revolutions of the coils.

Usage Tips

- Before use, the frame and device holder should be disinfected with chemicals once or twice a week and then wiped with gun oil to prevent corrosion.

- Clean the soot off the front contact spring regularly.

- Nipples and rubber bands get dirty easily and should be changed after each procedure.