Oblique binding

The bias tape is a popular sewing element that can be used to accurately and quickly decorate individual areas of clothing: necklines, dress armholes, sleeves and much more. Before proceeding with the inlay, it is recommended that you familiarize yourself with its features, technical characteristics, types and rules of use.

What it is?

Bias binding is a thin fabric strip of the applied type, which is cut in accordance with a particular pattern. A distinctive feature of this finishing material is the presence of additional folded allowances, which are fixed by ironing.

The name of the element comes from the cutting method - this process is carried out strictly at an angle of 45 °. Despite the fact that the bias binding looks quite simple, its production differs in some difficulties and technical features.

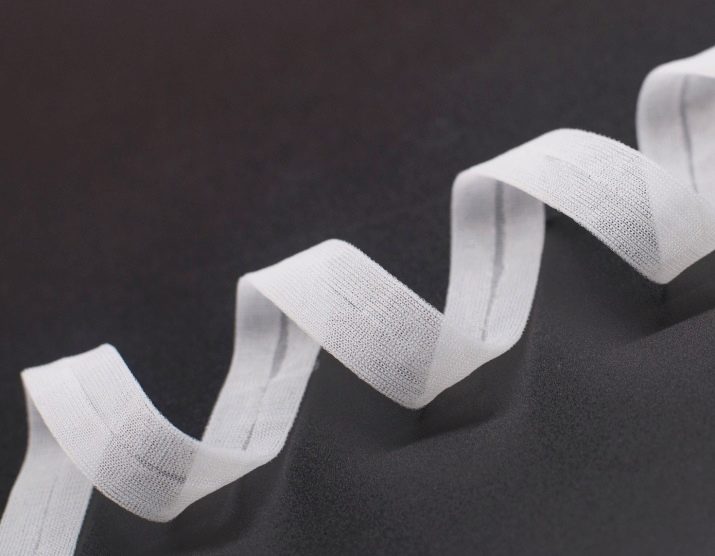

Since the fabric is always cut along an oblique line, this binding is characterized by certain advantages - elasticity, high performance and resistance to prolonged tension.

After several fabric strips are combined into a common strip or cut into a seamless tape, the edges of the bias tape are additionally overcast, folded and ironed. All this allows you to improve the quality of the finished product and increase the strength.

Before buying any bias tape, you need to pay attention to the main characteristics of such a product: width, length and thickness.

The result of the work depends on them. You can buy a sewing element at any specialized store.

What happens?

Based on size, structure, production material and other features, bias binding is classified into several basic varieties. Satin and knitted types are the most popular in sewing.

A distinctive advantage of the satin bias inlay is the presence of a characteristic shine of a glossy structure.

This sewing element is made of 100% synthetic material, which allows you to achieve an optimal price-quality ratio.

In addition to its good value, the wide satin variety has versatility, which is why it is often used for decorating colorful and colored items. This sewing accessory is also not without its drawbacks.

- Complicated care. The satin variety is characterized by rather difficult care and maintenance. It is strongly forbidden to expose such material to high temperature conditions. Otherwise, unwanted waves or any other deforming processes will be observed on the bake.

-

Fragility. As practice shows, this type of binding has a fragile cut. This feature directly affects the strength of the finished product - the sewing element often unravels and peels off.

-

Various deformations. With improper use or non-observance of external conditions, the satin binding often begins to fluff and become covered with numerous puffs. This process is often accompanied by the formation of pellets.

To avoid the aforementioned drawbacks of a satin inlay, many specialists resort to using jerseys. Distinctive features of this variety are high strength, matte structure and beautiful texture. No less important advantages of the knitted type.

-

Versatility. This variety can be used with natural and synthetic fabrics. Thanks to its good combination, such a binding is often used in the industrial sector and large manufacturing companies.

-

No deformation. In contrast to the satin type, various deforming processes, including waves and pellets, appear much less frequently on a knitted accessory. When buying such a product, you don't have to worry that it will creep out after a certain period of time.

-

Resistance to the external environment. A knitted tape is a unique type of sewing material that can be ironed under sufficiently high temperature conditions.

As for the disadvantages, the knitted sewing element has a rather high cost - 3-5 times higher than the satin variety. Sometimes a jersey product is difficult to find in specialized stores, due to a complex technological process.

And also the following types of elastic products are presented in stores.

-

Cotton. Cotton inlay is a versatile sewing material that is actively used for external and internal processing of the neck of clothes, creating complex shapes and finishing of bedding and underwear. Differs in good durability, beautiful appearance and relatively low cost.

- Into the cage. Despite the fact that this type is very popular in white, you can find a wide variety of numerous shades in stores. The main purpose of such a sewing element is the design and decoration of various elements of textile decor, outerwear and underwear. In some cases, this material is used in the manufacture of bags and shoes.

- Polyester. The peculiarities of the variety are a weak indicator of shrinkage, fairly flat edges and the ability to get a high-quality fit on the main cuts. This material is also characterized by high density, smooth structure and small width - up to 20 mm.

- From leatherette. The main advantages of a specialized inlay, which is made from an ecological leather substitute, are maximum resistance to external conditions, an attractive appearance and the absence of any deforming processes. The main disadvantage is its low versatility - this variety is usually used in highly specialized production.

- Silk. The main reason why this type of product is so popular with consumers is its velvet structure, which is distinguished by its expensive and sophisticated appearance.

The main disadvantages of this type are high whimsicality to care, a significant chance of unpleasant deformations and lack of strength.

- Chiffon. Bias inlays made of this material are characterized by the lightest weight, sparse structure and almost complete transparency. These sewing elements are commonly used for decoration.

Based on the above features of a particular variety, it is important to choose the right bias inlay. Otherwise, the sewing master may face various problems that will spoil the quality and durability of the finished product.

Where is it used?

Bias binding is a fairly versatile material that is actively used in numerous fields. This sewing element allows you to neatly and beautifully grind various cutouts on clothes, necks, edges of sections, as well as carefully decorate the outer part of pockets.

A feature of the bias inlay is the ability to process complex curly sections of the finished product, including angular, straight and semicircular shapes.

Due to its wide functionality and versatility, this element is often used to form decorative elements.

In large production workshops, an oblique inlay is used for sewing underwear, outerwear and home clothes, as well as creating many other types of wardrobe. This sewing element can be used both on a dress and on bedding, hats, and even for sewing some shoes, wallets, small bags and other products.

Recently, bias inlay has become widespread as the main or complementary material for the production of various jewelry: bracelets, brooches, elastic bands or hairpins.

Some jewelry accessories are additionally decorated with a similar fabric.

How to work with her?

Despite the fact that in stores you can find a fairly large number of various types of oblique inlines, many sewing masters make this sewing element on their own. In this case, there is no need to use specialized equipment, which is characterized by high cost.

A step-by-step process for creating a bias inlay.

-

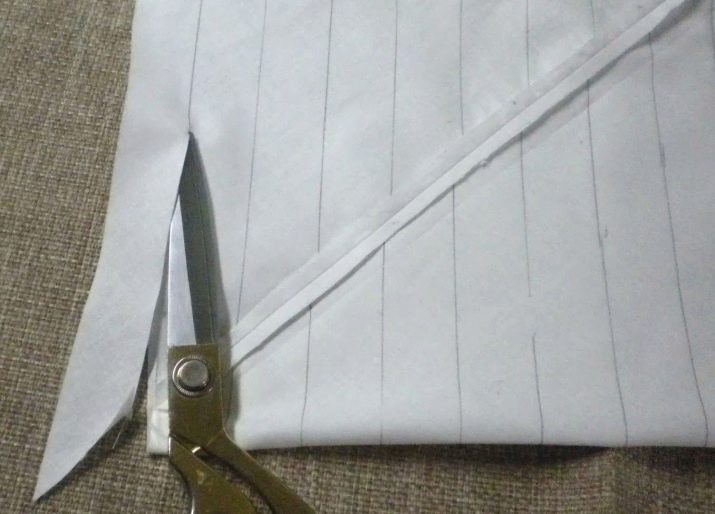

Carefully and carefully outline the knitted part for the future inlay. This process is carried out at an angle of 45 °. Otherwise, the garment will often bulge out and will not be able to fix properly on the main fabric. To make it easier to measure the required angle, experts recommend taking ordinary cardboard and folding it at a given angle. If the paper is flat, then the level is correct.

-

Draw all corners along the base. In order not to get confused in the process of sewing, they should be drawn in the same direction. Next, you should cut small strips of inlay in accordance with the selected drawing or diagram.

-

Connect the resulting corners with each other using ordinary needles.

After completing the above steps, you need to prepare a small piece of tracing paper, newsprint or any other material that has a fine structure. Further work is carried out on a typewriter.

-

Place the desired needle at the intersection of the corners. Start the sewing process.It is especially important to ensure that the stitch length is from 2 to 2.5 mm, while 2-4 stitches will be enough for a high-quality bartack.

-

When receiving a straight stitch with additional bartacks at the end or beginning of the product, you can remove the paper or newspaper used.

-

If the cardboard accidentally falls into the bartacks, it should be removed with a needle - this should be done very carefully and carefully so as not to damage the structure.

A step-by-step process for machining a round cutout.

-

Cut off a certain allowance towards the edge of the product. Next, unfold one of the parts of the bias tape and fold it over the front of the neckline. Subsequently, it is necessary to bend the existing edges of the garment approximately 1 cm deep and additionally sweep them along the ironed fabric line. It is important that the other end of the tape is over the folded edge.

-

Next, you should sew the inlay near the planned pattern, after which - bend the sewing element upwards and additionally iron the resulting seam. The final step will be to close the allowance with the previously ironed edge of the bias tape.

-

Subsequent actions are performed based on the desired model. In this case, the master should correct additional decorated elements, arrange certain fabrics or perform a series of actions in accordance with the intended scheme.

The final step is to work with the iron. To begin with, the masters recommend using simple fabrics or specialized materials that are self-fixed to each other. This will avoid mistakes due to improper handling of the heating device.

In addition to the above execution technique, anyone should know how to properly store a bias inlay. To keep this sewing element beautiful, smooth and even, it is recommended to wind it on a regular spool. For further use, it is enough to unwind the binding and use it as directed.