Everything You Need to Know About Adhesive Fabrics

Any seamstress knows about the benefits of adhesive fabric. When it is necessary to maintain a clear shape or give additional rigidity in the manufacture of fabric products, needlewomen use a special duplicating pad. For different purposes, different types are used, which are placed between the base and lining material.

Peculiarities

Duplicate fabric is a material with an adhesive layer applied to it. The adhesive base can be located both on one side of the base, and on both surfaces of the fabric. The peculiarity of using glue fabric is the absence of traces of glue on the finished product. The backing fabric is based on the cushioning material, which is necessary when sewing jackets, coats, jackets and other outerwear. The fabric lining is used to maintain the shape of the lapels, cuffs, collar posts.

Adhesive products are used for different purposes. When sewing clothes, a reinforcing pad is used for:

- shaping collars and pockets;

- processing the edge of the neck;

- strengthening the belt or flap on the pocket;

- the design of the bottom of trousers or skirts.

Sometimes adhesive fabric is used to repair clothing, especially when you need to apply a patch in a conspicuous place so that it is not conspicuous.

Another area of application of fabric with a layer of glue is in the manufacture of soft toys. Erect ears, paws, shoes for a doll and much more, for which the author of the toy has enough imagination, is also carried out with the help of an adhesive cloth.

Often a self-adhesive gasket is used to decorate various jewelry boxes, shoes, furniture, walls or other interior items using fabric.And also with the help of a glue pad, needlewomen can make hairpins or jewelry.

Views

Today, craftswomen have access to different types of adhesive fabric. They differ in the density of the base, the location of the adhesive on the material, the adhesive used and the field of application.

According to the composition of the base, adhesive models are divided into:

- woven;

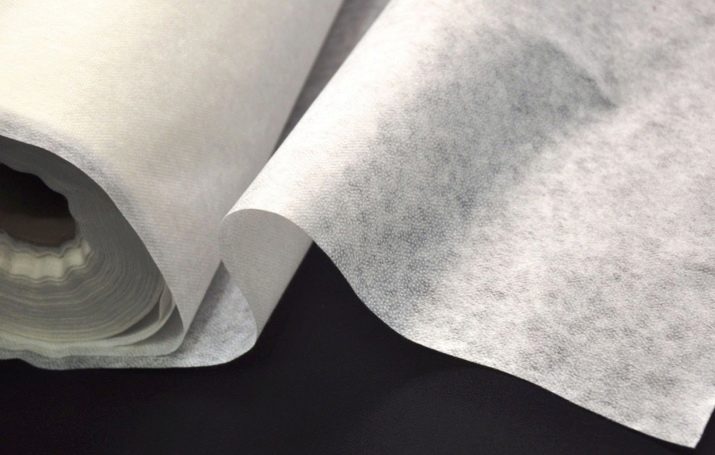

- non-woven;

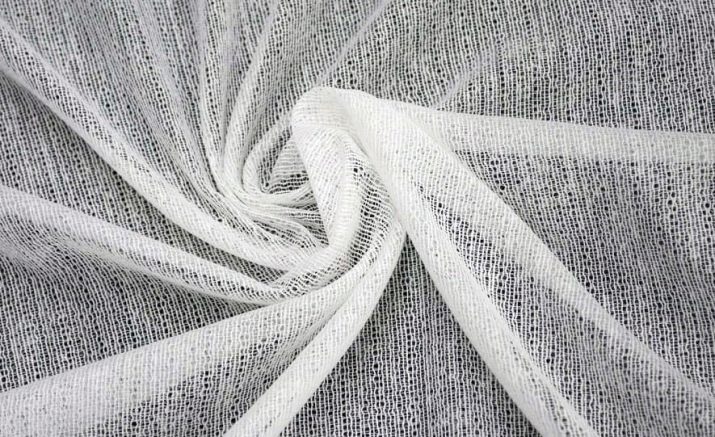

- knitted.

Woven base for interlining is obtained by weaving a lobular thread and a weft. The direction of the share thread must be taken into account when cutting.

Non-woven adhesive base obtained by pressing a mixture of synthetic fibers. Such material does not crumble the edges and there is no share guide, which makes it easier to work. But it should be borne in mind that even a non-woven fabric stretches more in some directions. Therefore, it is necessary to pay attention to this fact when working.

Self-adhesive fabric based on knitted fiber, easily stretches in different directions. This feature of the knitted glue base expands the possibilities of its use.

It should be borne in mind that duplicate models on a woven basis have a number of advantages over non-woven ones. They are more durable, drape well, do not create creases and are much stronger. In addition to the base for applying the glue, the glue used is also different. Three types of glue are used with different melting points:

- polyamide (melting point - 135⁰C);

- polyester (melting point - 200-220⁰C);

- polyethylene (melting point - 110-120⁰C).

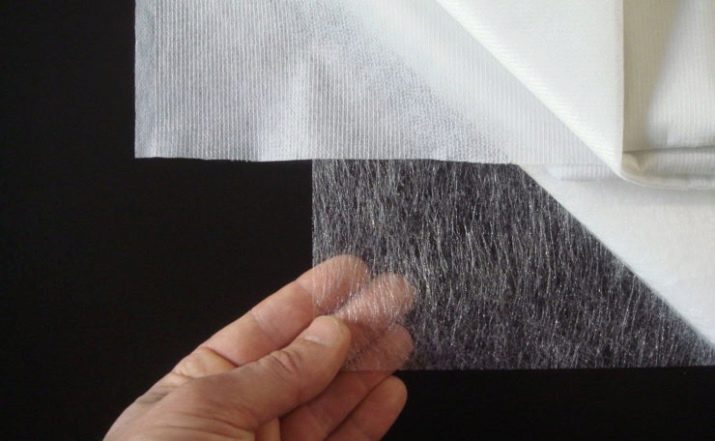

Glue can be applied to the base on one side, or the reinforcing variation has an adhesive coating on both sides, then it is called double-sided. When using the one-sided adhesive variation, the backing material is adhered to the base sheet, while the backing sheet remains free. If a double-sided adhesive model is used, then under the influence of high temperatures, both fabrics are glued, between which the seal is laid.

The method of applying the adhesive to the substrate is also different. The adhesive can be applied in a continuous strip, but spot application is most commonly used. All types of adhesive fabric are divided into elastic and inelastic, which determines the scope of application.

Elastic

Elastic duplicating products are created on the basis of textile fibers. There are thin lint-free models that are used for working with delicate materials. For products made of soft and dense fabrics, an adhesive fabric on a knitted basis with a pile is used. The presence of villi allows to hide traces of glue.

Inelastic

Inelastic adhesive products are made from woven or nonwoven fabrics. They do not stretch, do not deform and give the products a fair amount of rigidity and strength. Duplicate chiffon backing is used to define sheer blouses and dresses. Calico adhesive models are used to create corsets. Dense hot-melt fabric is used to strengthen fur and leather products.

There is also a special thermal collar fabric. It is covered with a continuous layer of glue and does not bend well.

A paper-based glue pad is used to sew decor to clothing when it is necessary to protect the base fabric from stretching. After the end of the work, it is removed.

The following self-adhesive materials can be found on the market.

- Dublerin... Knitted or cotton fabric with one-sided glue application.

- Non-woven... Non-woven fabric. It can be two-sided and one-sided.

- "Cobweb". Thin synthetic fiber material. On sale it is found in the form of a narrow tape, but it can also be a canvas. In the form of a tape, the "spider line" can be on the paper layer or without it.

- Sintepon... Sealant with spot adhesive.

- Dekovil... Material similar in appearance to leather. Used to strengthen belts, bags.

- Side seal. Used in the manufacture of bags. Outwardly resembles felt.

- Collar thermal cotton fabric... It appeared on the market relatively recently, but has already found recognition among seamstresses.

Popular manufacturers

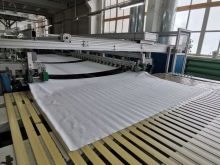

The manufacturing process of the adhesive fabric is simple and low-cost, therefore, almost all spinning and weaving factories produce glued duplicating fabrics.

The most famous manufacturers of fabric, and, accordingly, of glue, are factories located in Ivanovo and Ivanovo regions:

- plant "Rodniki-Textile";

- spinning and weaving factory "Shuiskie chintz";

- Ivanovo textile factory.

Additionally, you can note the following manufacturers:

- Donetsk manufactory - one of the best enterprises in Europe;

- OJSC "Trekhgornaya Manufactory" - one of the oldest in Russia.

This is not a complete list of famous fabric manufacturers in Russia, whose products can be found on the market.

What to consider when choosing?

The area of application is an important factor in the selection of the adhesive strip. If you have to work with materials for sewing products from dense fabric, such as coats, jackets or fur coats, then you must use a duplicate model with a high density, for example, dublerin. For sewing products from fine fabrics, various types of non-woven adhesive fabric are used. To strengthen the jerseys, you need a knitted adhesive fabric.

For processing the bottom of a dress or trousers, a "cobweb" is suitable - a thin tape of isotropic fiber with an adhesive layer. The basic rule for choosing an adhesive variation: the density of the working web and the used duplicating material must match. Differences can only be in rigidity.

How to use it correctly?

Before you start working with the glue pad, you need to do a test check on the underlying fabric. To do this, you need to take a piece of working material and the selected duplicate material. Attach the selected fabric with the adhesive side to the wrong side of the flap and iron it through gauze or paper. Check the finished result for compliance with the requirements. If everything suits you, then you can continue to work with the product.