Ramie fabric description

Rami is a unique canvas, and many needlewomen want to know what it is. The composition and properties of nettle fabric attract many designers who create collections from sustainable materials. Ramies are not produced in Russia, but local brands successfully create collections of clothes and other items from ready-made canvases.

What it is?

Once upon a time, ramie (Chinese nettle fabric) was the privilege of noble people in China. It was from her that they created magnificent ceremonial sets worn on special occasions. Ramies are distinguished by a completely natural composition, original color and structure of fibers. In Russia, the production of this type of fabric is not carried out on an industrial scale, since there are no climatic conditions for obtaining high-quality raw materials. Basically, nettle is made in Singapore, Armenia, Togo, Vietnam, China, Japan, South Korea, India and Indonesia. In Asia, it is found under the name mosi.

Initially, ramie refers to the entire genus of herbaceous plants that are part of the nettle family. This spinning culture is considered one of the oldest. Also known as Chinese nettle, ramie white. Raw materials grows mainly in East Asia, in tropical and subtropical climates. This subspecies does not have hairs that leave burns when it touches the skin. Within a year from 1 plant, 2 to 6 harvests are obtained.

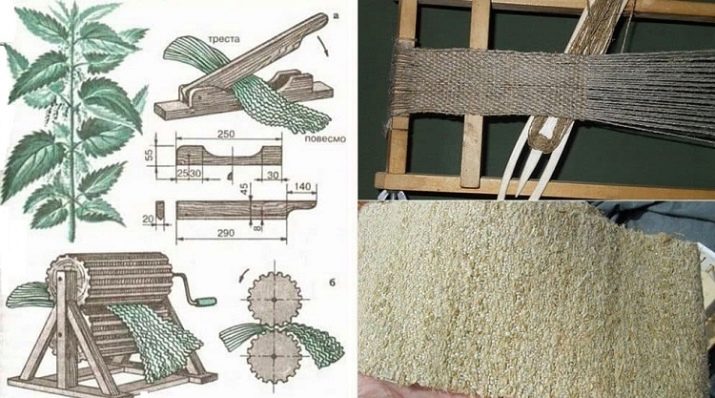

The production process of raw materials to create a material goes through several stages:

- collection of raw materials during the flowering period (with darkening of the stem);

- bark removal;

- cutting off the parenchyma;

- separation of resins by chemical and biological methods;

- mechanized disassembly of the stem into fibers.

The resulting threads undergo subsequent processing, giving them softness and elasticity.The yarn is dyed in different colors. The finished canvas with a dull sheen looks like flax. In the production of yarn, both pure ramie fibers and their mixture with cotton (cambric) and wool are used in a ratio of 60 to 40%.

The modern textile industry produces ramie from 3 types of raw materials:

- white;

- green;

- Nanda.

The fibers of all these types of nettle are bast, with a high content of resins and essential substances. During the production process, they are removed from the composition.

Origin story

The first documentary evidence of the use of this material is considered to be the discovery of a Scythian mound of the 3rd century in Eastern Europe, where the remains of ramie clothing have been preserved. But there is evidence that Japan and China began to use this raw material even earlier in the manufacture of fabrics. By some estimates, nettle yarn has a history of about 5,000 years.

In European countries, ramie began to be widely used already under Queen Elizabeth I. In Asia, they learned how to make yarn from this nettle much earlier. The main difficulty was the separation of the fibers. Before this operation began to be carried out industrially, up to 50% of the raw material was lost at the stage of splitting the stems. It is rather difficult to separate the fibers glued together into thinner components.

With the beginning of the industrial import of rami to Europe in the 18th century, interest in it gradually increased. But other plant-based fabrics were much more affordable. That is why mass garment production was launched only in the 30s of the XX century. Then again there were many years of oblivion. In Russia, they learned about rami by the end of the 19th century. It was during this period that nettles of this type began to be used in the Caucasus as a raw material for textile production.

The first to grow ramie were the inhabitants of the Malay Peninsula... The humid and warm climate of this area makes it possible to obtain raw materials of the highest quality. In temperate zones, the stems are coarser, they are used exclusively for the production of material for technical purposes. A new round of popularity awaited ramie at the end of the 20th century. Eco-friendly materials became fashionable, and designers remembered about nettle fabric.

Today, clothes from these natural raw materials are produced in entire collections, and in South Korea, a show is held annually, where all items are made exclusively from ramie.

Characteristics and properties

Ramie fabric is produced in the form of canvases with a translucent structure. The interlacing of the threads is dense. The surface is tactilely pleasant, has a light silvery sheen that does not disappear after dyeing the threads. The main characteristics of the material are as follows:

- plain weave;

- fabric width - 1380 or 1450 mm;

- density - 210-240 g / m2;

- shrinkage is no more than 2-3%;

- strength is 6 times higher than cotton;

- high wear resistance;

- hygroscopicity - 16-18%.

Such indicators give the material certain properties. Rami does not generate static electricity as there are no synthetic fibers in the fabric. At the same time, it has a high ability to absorb moisture and vapor permeability. The canvas is good air permeability. Complex production significantly affects the cost: the average price of 1 running meter of nettle material reaches 17 euros.

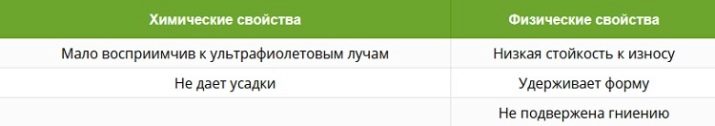

When planning sewing products from ramie fabric, it is worth examining all its advantages, features and possible disadvantages. It is customary to refer to the obvious advantages as follows.

- The comfort of body products. The skin in such clothes breathes, air exchange is not disturbed. In countries with hot climates, this avoids excessive sweating.

- Bactericidal properties... The material is well protected from damage by pathogenic microorganisms, does not grow moldy when stored in high humidity conditions.

- Resistant to UV rays. The material does not fade when dried in the sun, retains the brightness of the coloring for a long time.

- Ease of care... Ramie textiles are easy to wash and iron at low temperatures.Due to its dirt-repellent properties, it hardly gets dirty.

- No deformation. The fibers are not subject to stretching and shrinkage. Clothes made from them retain their appearance for many years.

- Environmental friendliness... In the manufacture of textile fabrics, potentially hazardous dyes and other substances are not used. It is environmentally friendly and safe.

- Hypoallergenic... Nettle is suitable for everyone, including people with allergies and babies with sensitive skin.

Also, the material without loss tolerates contact with acids in a weak concentration. However, the ramie fabric has noticeable disadvantages. It is inelastic, which means that when taking measurements or buying ready-made clothes, it is imperative to check the fit of the product to the figure. Also, the canvas has an average resistance to mechanical abrasion, with frequent washing and active use, it wears out rather quickly. Exposure to powdered stain removers will gradually wash out the color from the fibers, making the material faded.

Another significant disadvantage is the limited choice of cut. Brittle fibers do not allow the creation of complex products. Most often, ramie clothes have a loose fit, a semi-adjacent silhouette.

Application

Ramie fabric is usually divided into categories. Fiber from plants cultivated in temperate climates is considered technical. They turn out to be less long, rather coarse in structure. Cloth from such material is rarely woven. Most often, the fibers are used to make wicker products and souvenirs: from washcloths to mats.

Rami white from plants in southern latitudes has a wider application. Textile fabric from it is used in the manufacture of the following products.

- Baby clothes... The material is hypoallergenic, light and soft, does not chafe sensitive skin. Eco-friendly fabric is suitable for the production of thin underwear and baptismal shirts. When mixed with ramie cotton, nettle cambric is obtained, very thin and light, but not too strong.

- Bedding... Rami is used as a filler in pillows, blankets, mattresses. The fibers do not cake and retain their elasticity for a long time. This stuffing dries easily when it gets wet. It keeps warm and shape well, is hypoallergenic, suitable for children.

- Home textiles. High density allows you to create high-quality kitchen towels, napkins, tablecloths from nettle fabric. Light sheen and the ability to drape beautifully makes the material an excellent choice for curtains: both plain and printed. High quality bed linen is successfully produced from ramie, at a cost it belongs to the premium class.

- Casual wear. A clean canvas is used quite rarely, more often mixed materials are used, which have a good margin of safety. Depending on the density, blouses, dresses, skirts, trousers and suits for men's wardrobe are sewn from it. In Asian countries, ceremonial national clothes made of nettle cloth, decorated with embroidery, are highly valued. You can find ramie clothes from brands such as Zara, Mango.

These are the main areas of application in which ramie fabric is most in demand. Its fibers are also added to wool in the manufacture of knitwear in order to increase the softness, comfort of products to wear, and improve their resistance to shrinkage. From 100% ramie, linen is rarely woven today. Such textiles turn out to be much coarser, therefore, fabrics with a cotton or linen component are used, which impart improved properties to the matter.

The most popular combinations with nettle fiber in the textile industry are pamuk or viscose. They are used to create fabrics for business suits that are not subject to intense creasing.

Moreover, the content of plant fibers in the composition rarely exceeds 30%.

Care Tips

Ramie fabric, like other types of natural fiber textiles, needs special care.Recommended for her is a soft hand wash without bleaching. In the presence of stubborn stains, it is permissible to use a professional dry cleaning. The basic care recommendations are as follows.

- Washing by hand or machine, on a gentle cycle... The temperature range is 40-60 degrees Celsius. It is recommended to wash ramie clothes separately from other things, using special washing gels.

- Pressing machine or manual, without strong twisting of products... Kinks are difficult to fix. For machine spinning, set the drum to medium speed.

- Drying is natural. Before hanging the product, straighten it. Good ventilation is important when drying indoors. Outdoors, it is also possible.

- Ironing at a temperature of +150 degrees... Beforehand, things are turned out to the wrong side. Products can be steamed.

It is not recommended to paint independently, bleach or expose nettle cloth and products made from it to other influences of aggressive chemicals. It is necessary to dry and fold products in a horizontal position, especially when it comes to natural 100% ramie. Its fibers are more brittle, and it is quite difficult to smooth out the resulting folds even with a steamer.