Percale: characteristics, composition and application

Percale is a beautiful and practical material and is widely used in light industry for sewing bed linen and clothing. Due to its high performance and excellent decorative properties, consumers increasingly prefer it to other materials in this price category.

What is this fabric and how is it made?

Percale is extremely popular in today's fabric and textile market. The excellent working qualities of the material are due to the presence of cotton threads in its composition, which determine its basic properties. However, percale differs from other cotton-containing materials in its manufacturing technology, in which long-staple cotton is impregnated with special solutions. This process is called sizing and allows you to get a particularly durable and pleasant to the touch material.

As an adhesive composition - dressing - a mixture of potato starch, glycerin and animal fats is used. The use of sizing technology can significantly increase the wear resistance and antistatic properties of the fabric, and also eliminates excessive hairiness, gives a pleasant smoothness and eliminates thread breakage.

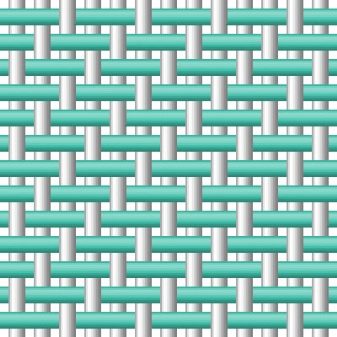

In the manufacture of percale, a dense cross type of weaving is used, which, in combination with the processing of each thread with an adhesive composition, results in a very strong material in its structure. For the production of percale, medium and thin untwisted threads are used, while their density is about 90-160 pieces per 10 cm. At an earlier stage of production, percale resembled rubberized fabric in its appearance and was used for sewing parachutes.

However, with the development of high-tech weaving production, modern material looks quite presentable and is actively used for sewing clothes and bed linen. Percale dyeing is often done by the printed method, using complex large-scale paintings and photo printing as a pattern. As dyes, high-quality compositions are used that do not contain toxic or poisonous components, and are quite resistant to regular washing and fading.

Characteristics and composition of the material

Percale contains cotton and linen, the fibers of which are evenly coated with glue. Sometimes polyester fibers are added to cotton and linen threads, thanks to which the fabric becomes even softer and more elastic and acquires a beautiful shine. However, the proportion of synthetics in fabrics is usually small, which is why percale can be considered a natural and environmentally friendly material. Important performance properties of the material are its density and resistance to external factors. The fabric behaves ideally at low temperatures, which is why it was at one time actively used in shipbuilding for sewing sails and in aviation for covering the hulls of the first aircraft.

However, along with high density and strength, percale combines extraordinary lightness and tenderness. It is the combination of these seemingly poorly compatible qualities that makes it unlike other materials and significantly expands the scope of its application. In addition, products made of percale are capable of retaining the brightness of colors and original shapes for a long time. Another important characteristic in the description of the material is its non-flowing and pliability during sewing. Thanks to these properties, the fabric is ideal for sewing complex models with an abundance of lace inserts and other decorative elements.

Advantages and disadvantages

High consumer demand and a large number of approving reviews about percale are due to a number of indisputable advantages of this material.

- The fabric is very durable. With careful use and timely care, percale products can serve for 10 or more years. On average, each such product can withstand up to five hundred washings without losing its initial characteristics.

- Complete absence of pellets. Even with numerous washes and active use, for example, bed linen, the surface does not roll and looks like new.

- Due to the presence of synthetic threads in the composition, percale is very easy to iron, and products in which the proportion of polyester is slightly higher do not require it at all.

- The fabric does not cause allergic reactions, which is why it is often used for sewing children's bedding sets.

- Despite the presence of synthetic fibers, percale does not contain static electricity.

- The material has a very high strength, however, at the same time, it is quite light and airy. Due to its dense structure, the fabric is ideal for sewing pillowcases and pillowcases. Percale does not allow down and feathers to come out, but at the same time ensures normal air exchange, promotes the evaporation of excess moisture and prevents unpleasant odors.

- The fabric is distinguished by high temperature-regulating properties: in summer it will not be hot to sleep under such linen, and in winter it will not be cold.

- The material practically does not shrink and even after numerous washes it does not lose its original shape and does not deform.

- Percale is easy to wash and has a moderate dirt-repellent effect.

However, with many obvious advantages, percale also has weaknesses.The main disadvantages include a rather high cost, in comparison with other cotton and linen fabrics. On average, one meter of fabric with a standard width will cost more than 300 rubles.

In addition, the material is not recommended to be bleached or washed in hard water. This is due to the presence of an adhesive component in the fabric, which is adversely affected by the factors listed above. The ban on bleaching makes it difficult to care for white products, which is why they quickly lose their original appearance and look somewhat washed out.

Manufacturers

In Russia, most of the fabrics entering the domestic market are produced by weaving factories located in the city of Ivanovo. The enterprises produce a wide assortment of percale, represented by fabrics of various colors and compositions. From foreign manufacturers, weaving factories in India, Egypt and Pakistan are supplying material to the Russian market. There are slightly fewer products from Turkey and Uzbekistan.

France was and remains the recognized leader in the production of percale, whose weaving factories provide practically all of Europe with this practical and durable fabric. Along with their French colleagues, Italian and Portuguese masters are successfully engaged in the production of percale, whose products are elite fabrics and are quite expensive. So, the cost of a kit in the middle price category is within $ 460.

Where is it used?

The scope of application of percale is wide enough and before talking about where this practical and comfortable fabric is used, one should refer to its classification. A modern manufacturer produces two types of material: household and technical. The first is characterized by increased density, necessary to prevent the eruption of down and feathers, and, accordingly, is used for the manufacture of bedding sets. At the same time, household linens are highly hygroscopic and breathable. This allows you to use bed linen made of percale throughout the year. In addition, due to its high hygienic properties, the fabric is used in sewing women's blouses and dresses.

The second type of percale is technical - although it is no longer used in aviation, however, continue to be used for sewing parachutes, sails and awnings. Such material has a lower density in comparison with household material, therefore it is not used for sewing pillowcases and pillowcases. In addition, work clothes, curtains and a tent can be sewn from technical percale, and in the furniture industry, upholstery for sofas and armchairs is often sewn from it.

Comparison with other materials

Percale is often compared to other materials used in bedding. Based on the comparative analysis of experts and consumers, the material is a strong average in its niche of paintings, and in some respects it even surpasses some of them. So, if we compare percale and ranfors, then the density of the first is undoubtedly higher, however, the second is made from twisted threads, due to which it is softer to the touch and easier to wash. In general, these two materials have a lot in common: they both practically do not shrink after washing, do not fade in the sun and are pleasant to the body.

When comparing softcotton and percale, it is difficult to give the palm to one of them., since the materials are somewhat similar, and both have fairly high working qualities. However, there are still some differences. So, the composition of the first includes viscose and synthetic microfibers, which is why the material has much better hygroscopic properties than percale, therefore it is often used in the manufacture of towels and home clothes.

In addition, the softcotton is easier to iron and less wrinkling. But at the same time, the content of artificial fibers in percale is much lower, therefore, in terms of hypoallergenicity and environmental friendliness, it easily bypasses softcotton.

If we compare tencel and percale, then in terms of operation, percale, of course, is better and more convenient. Tencel, which is based on wood pulp made from eucalyptus, has a low resistance to deformation and shrinkage and requires more careful and gentle care. So, many manufacturers recommend only dry cleaning for products made from Tencel. However, in terms of hygroscopicity, ventilation and thermoregulation, Tencel has the best performance.

Criterias of choice

There are a number of important factors to consider when buying percale.

- Due to the fact that the fabric belongs to rather expensive luxury materials, the price for it cannot be too low. If there is a product on sale at a suspiciously low value, then most likely it is either a fake or a defective canvas.

- In order to be absolutely sure that there is really percale on the counter, you need to pay attention to the interweaving of the threads.

Upon visual inspection, a cross type of weaving with a long length of threads is clearly visible on the percale fabric.

- To visually determine the density, and therefore the strength of the fabric, it is necessary to look through it at the light: if the material is truly high-quality, then there should be no gaps. Otherwise, it is most likely a fake, and it is better to refuse to buy such a translucent canvas.

- If possible, it is recommended to pull the thread out of the fabric and set it on fire. If the canvas is a real percale, then the smell will resemble the smell of burnt paper. If synthetic fumes are felt and the thread begins to melt, then there is a counterfeit on the counter.

Care features

In order for percale products not to lose their attractiveness for a long time and to serve as long as possible, they must be properly looked after. The material belongs to the category of rather demanding fabrics to maintain, therefore washing and ironing must be done according to certain rules.

- The water temperature during the first wash should not exceed 45 degrees. It is strictly forbidden to use bleaching agents, as well as to soak or boil products. Before washing, it is recommended to place the laundry in a cool room and allow it to stand for a while. In addition, the laundry must not be starchy and use too hard water for washing and rinsing.

- All subsequent washings can be done in water with a temperature not higher than 80 degrees, although 60 are considered optimal. Only mild detergents or powder for children's clothes are allowed for use. A conditioner is also recommended. Washing in an automatic washing machine should be carried out at a power of no more than 800 rpm, and the drum load should not exceed 50%. Pillowcases and duvet covers should only be washed inside out. This will help preserve the pattern and help wash the laundry better.

It is recommended to spin at low speed. This will significantly reduce the load on the fibers of the fabric and significantly extend the life of the product.

- After spinning the laundry, the items must be removed from the drum immediately. It is forbidden to leave percale in a wet crumpled form for a long time. You can dry products both vertically and horizontally, without fear of hanging them in the sun: percale is not prone to fading, and the sun's rays will allow the material to dry quickly and evenly. However, when hanging it, it should be borne in mind that wet percale crumples very much, therefore, when placing it on a rope, it is necessary to wrinkle the products as little as possible. It is recommended to iron percale products immediately after drying, and the optimum temperature for ironing is 140–150 degrees.

As you can see from the above, percale is quite capricious in maintenance, so if you are not ready for such painstaking and meticulous care, then it is better to purchase another material.

However, with the right choice and strict adherence to the rules of operation and washing, percale products will delight their owners with bright colors, durability and excellent appearance of this expensive and chic fabric.

For information on how to properly iron percale bedding, see the next video.

Good article, detailing the characteristics of the fabric and its care.