All about rip stop fabric

The desire of many to learn everything about the properties and features of rip-stop fabric is explained by its record popularity and outstanding performance. In this case, we are talking about a material, the main characteristic of which is its strength, due to the special weaving structure, as well as the presence of reinforcing threads.

Today, different types of such fabric are available, which differ from each other in their properties and characteristics. Moreover, they all find wide application.

What it is?

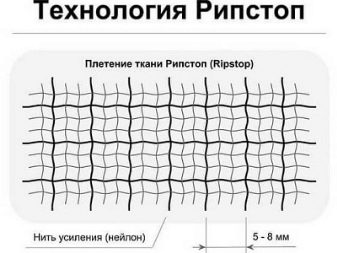

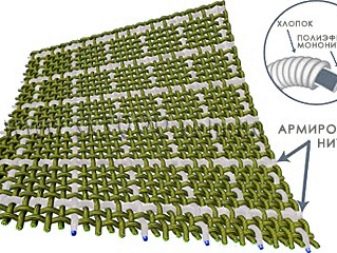

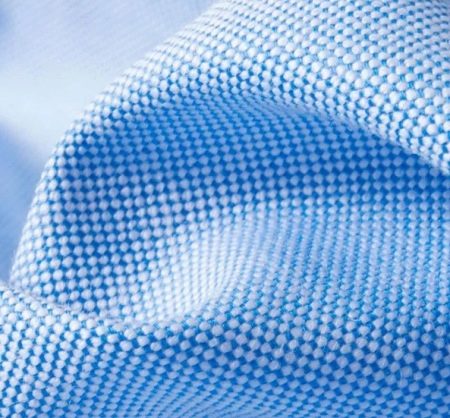

The increased strength of the rip-stop fabric is provided due to the technology of its production. And first of all, we are talking about weaving patterns, in accordance with which reinforcing threads are cross-passed through the base with an interval of 5 to 8 mm. It is important to note that the volume of the reinforcing components (fibers) is superior to the load-bearing component. That is why you can see a checkered pattern on the finished fabric. By the way, the comfort of use (socks) is provided by a natural cotton braid of the reinforcing mesh.

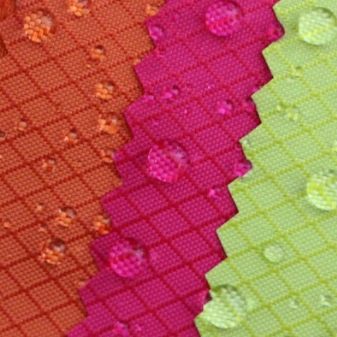

An important feature of the production of rip-stop lies in the various impregnations of the material, namely:

- water and oil repellent;

- frost-resistant;

- resistant to acids;

- dirt-repellent.

In addition, the production technology provides for the presence of the following fibers in the material:

- antistatic;

- kevlar;

- silicone;

- teflon;

- aramid.

Analyzing the key characteristics of this type of modern textiles, one can single out its main and most significant advantages. Regardless of the type of fabric, the rip-stop class has the following indisputable advantages.

- Resistant to tearing.

- They are not rubbed or stretched regardless of the severity of the operating conditions.

- They practically do not wrinkle, which greatly facilitates care.

- They have high performance due to special impregnations. In parallel, the material is breathable due to the presence of natural ingredients in the composition.

- They retain their appearance even after repeated washes.

- They are lightweight. This is most relevant for workwear.

- They are soft and pleasant to the touch, despite the presence of reinforcing threads.

- Can be washed using almost any chemical agent.

- Easy to dry and iron if necessary.

- Pills and puffs do not form on things.

Naturally, one cannot do without focusing on the description of certain disadvantages of the material. And in this context, it is worth highlighting the following points.

- Synthetic fabrics are not the best solution for long-term wear. This is due to the fact that air is poorly passed through, moisture is retained.

- The accumulation of static electricity is possible in the absence of special impregnation.

- Due to the complexity of production, some types of rip stops have a relatively high cost.

History of appearance

First of all, it is worth paying attention to the features of the name of the material in question.... It represents two English words: rip and stop, which in this case are translated as "to break" and "to stop". By the way, you can find different spellings of the name of the fabric: "rip-stop" and "rip-stop". This is due to the two-sidedness of the original. This high-strength material was born thanks to the leadership of the North Atlantic Alliance. It was at the request of NATO that the development of a fundamentally new production technology was initiated back in the 20th century. Later it was modernized and today it is widely used by many fabric manufacturers.

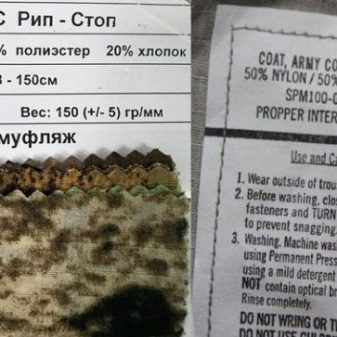

It is worth noting that the first rip stop samples were exclusively camouflaged. These samples of the material differed in bulk and coarseness when compared with modern fabrics.

Due to the active implementation of innovative solutions, manufacturers now have the opportunity to produce products of a wider palette and at the same time vary their properties.

Species overview

Today the potential consumer is offered a fairly wide range of the described fabric. Taking into account a number of features and technical issues, the following types of rip-stop material can be distinguished.

- One of the current achievements of modern manufacturers is the creation of the "Hypora" fabric., which is characterized by maximum water resistance of the inner and moisture resistance of the outer surfaces. Similar results were achieved by the interweaving of a 3-layer coating and a microporous polyurethane-based film. This type of rip stop retains its properties when the temperature drops to -40 degrees. Another important feature is the increased resistance of the material to the effects of gasoline, engine oil and other corrosive liquids. This type of fabric is used to create the inner layer of various products.

- A fabric called "Moss" (cotton and synthetics, 35% and 65%, respectively) - high-quality material for elements of military uniforms and clothing for hunters. One of the distinguishing features is a special pattern that allows you to effectively mask.

Equally important properties are fabric impregnation, providing windproofness and moisture resistance, as well as strength and durability.

- "Flora" - a kind of fabric with characteristics very similar to "Moss". The main difference here will be the color palette, which is dominated by green, black and brown.

- "Twill" - rip-stop for sewing workwear, characterized by strength and increased density.

By composition

Taking into account the presence of certain components in the composition of the described material, it can be of the following types.

- Naturalmade of cotton and reinforced polyester thread. Cotton in this case can be replaced by wool.

- Mixed, in the manufacture of which both natural and artificial components are used as raw materials in equal proportions.

- Nylon... This refers to the material from which both the reinforcing threads and the fibers for the warp are made.

- Polyester, similar in characteristics to the previous version, but differing in rigidity and weight.

- Ballistic, which differs from other varieties in increased strength. It is worth noting that at one time the material was used in the manufacture of body armor.

By density

It is important to note once again that the manufacturing technology of the fabric in question is rather complicated. In some cases, this is reflected in the cost of both the material itself and products made from it. However, another determining factor here will be density, taking into account which the following types of rip stops can be distinguished.

- 220 to 250 g / cm2 - fabric designed for use with relatively light loads. It contains cotton and polyester and is breathable.

- 200 g / cm2 - this weaving "Tormofort". The material consists of 100 percent reinforcing threads and, in most cases, is impregnated with oil-repellent or refractory agents.

- 280 g / cm2 - weaving class "Super protection", which is currently the most dense.

Separately, it is necessary to pay attention to the universal membrane fabric, consisting of two layers. The inner part is a thin film (membrane), and the outer part is dense polyester.

Areas of use

Today, the considered type of fabric with increased strength has found wide application in various fields. The material is used in the manufacture of clothing, accessories, items of equipment and awning products for the following activities:

- production;

- military;

- tourist;

- commercial;

- sports.

Particularly dense and durable samples of such textiles are the raw material for the production of special equipment, as well as narrow-profile workwear and uniforms. Softer fabrics are relevant for creating household items. At the moment, rip stops are used to make:

- the daily uniform and equipment of military personnel, employees of the Ministry of Emergency Situations, firefighters, medical workers;

- body armor, including army, gun cases and other protective equipment;

- sportswear;

- equipment for tourists (backpacks, sleeping bags, tents, tents, etc.);

- durable backpacks and bags for various purposes;

- awnings and awnings, including commercial tents;

- covers for gadgets;

- paragliders, parachutes, balloons and kites;

- sails for kites and yachts;

- flags, banners and streamers.

Naturally, this is not a complete list of ways to use the material described.

Care rules

Taking into account all the features, rip feet is a fabric that is very practical and easy to clean. At the same time, careful use and competent maintenance of products from it will help to maximize their service life. In doing so, it is strongly recommended to keep in mind the following basic rules.

- Cleaning of wet things is inadmissible. First, they must be dried and only then the dirt must be removed with a brush. This is especially true for backpacks, bags, and camping tents.

- Small holes and cuts can be repaired with self-adhesive tape. If we are talking about large-scale damage, then you will have to apply patches on both sides and sew them with nylon thread.

- It is not recommended to keep the products under the influence of direct ultraviolet rays for a long time, which can destroy the outer protective layer.

- Items that are rarely used should be periodically ventilated and cleaned.

In addition to all of the above, it is important to focus on how to properly wash and dry rip feet. And in this case, the following key points should be considered:

- both hand and machine wash are acceptable;

- the water temperature should not exceed 50 degrees;

- it is possible to use any cleaning agents, including bleaches (the exception will be preparations containing trichlorethylene);

- in the presence of strong contamination, preliminary soaking in soapy water is recommended;

- it is undesirable to use spinning at high speeds;

- you can dry things indoors or outdoors, avoiding direct sunlight as much as possible.

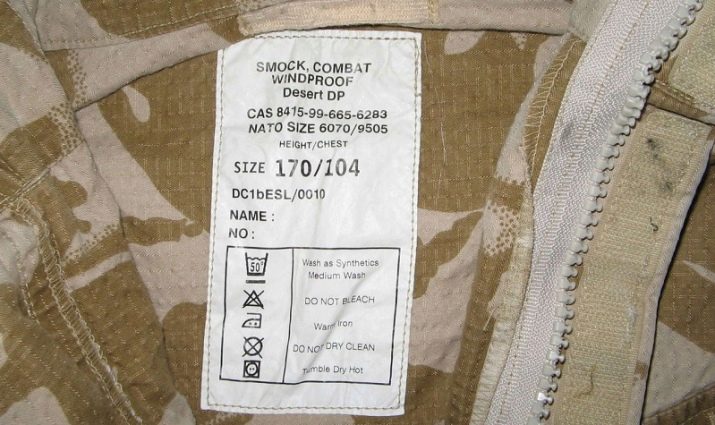

In the process of developing this fabric, the peculiarities of its operation were taken into account. This means that there is no need to iron things after washing or long-term storage when folded. However, deep creases are often formed, the elimination of which will require:

- spread the thing on a flat surface;

- wet a little using a spray bottle;

- lay out gauze folded in two layers or other fabric on the surface;

- iron, taking into account the temperature indicated on the label (if there is none, it is better to iron the wrong side first).

An alternative to this method can be the use of modern steam generators. But in any case, after the described processing, as well as washing, it is recommended to store the clothes on hangers (hangers).

Review overview

Analyzing reviews and testimonials from real users, you can immediately understand which characteristics of the rip foot tissue are key. So, the owners of things made of this material focus on their strength... This, judging by the reviews, is most relevant for fans of fishing and hunting, as well as fans of outdoor activities. At the same time, many note in their comments that in such clothes you can go to the forest and go out into the city.

No less important points - it is the convenience and safety of using products. The overwhelming majority of users claim that things made of rip feet can be worn in all weather conditions without fear of chafing and allergic reactions. In parallel, lightness, windproofness and waterproofness (up to a certain point) of the fabric are indicated as the main advantages.

It is important to take into account that a large number of mostly positive reviews are published not only about clothes made from rip-stop... In such comments, we are also talking about backpacks, tents, awnings and many other products. Hunters, fishermen and tourists alike find this material to be durable and wearable, as well as durable when properly cared for and maintained. Many fishermen praise boat awnings made from this material. At the same time, they focus on effective protection against moisture, even in difficult weather conditions.

Some reviews indicate that direct sunlight may affect the fabric. For the rest, the overwhelming majority of commentators list only its merits.