Everything you need to know about fabric sublimation

From time immemorial, people have tried to decorate their clothes, household items, so that they bring joy to those around them. Previously, embroidery, appliqué on fabrics and other types of needlework could help for this purpose. With the development of technology, processes are improving, which means that there are more options for improving clothing design.

One of these technologies at the moment is the so-called sublimation on fabric, which has recently entered the service market and quickly won the trust of a large number of customers. Let's consider the features of the method in more detail.

What it is?

Sublimation is the process of applying a bright picture or photograph to a fabric using professional equipment and under the influence of high temperatures. Thanks to this technology, the picture literally penetrates the tissue, becomes one with it at the cellular level, as a result of which the picture is as bright as possible. Under the influence of a temperature of one and a half hundred degrees, a special paint passes from a liquid to a gaseous state, it is transferred from a certain source to the fabric, which must necessarily include artificial fibers (at least 50%). It is worth noting that the most clear image quality can be achieved if you use a light material as a base.

Most often, the sublimation printing method is found in the field of souvenirs: these are all kinds of cups, pillows, T-shirts, flags.

The technology we are considering is especially popular among large and small companies that order corporate products for the office or for their clients.

Separately, it should be noted about the pros and cons of sublimation printing on fabric. So the benefits:

- printing goes without rinsing, which saves time and money;

- does not harm the environment;

- images are of high quality;

- the obtained specimens are resistant to fading;

- you can use a wide color palette, rich shades;

- numerous washes will not interfere with the pattern;

- printing even complex images with a large number of colors does not take much time;

- the number of editions is not limited by anything.

The disadvantages of the sublimation printing technology include the following:

- in the technological process, it is important to observe strict conditions, which is not always convenient for manufacturers;

- a high-quality result can be obtained only when the fabric base has a light shade, although customers often wish to choose other colors;

- the paint is applied exclusively to the fabric, which contains at least 50% synthetic fibers, which does not always suit customers who prefer natural materials.

What fabrics are suitable?

Natural materials, such as cotton, linen or wool, do not absorb paint well, so it is impractical to use them for sublimation technology on fabrics. After the item has been washed 1-2 times, there will be no signs of a bright pattern on it. Therefore, the best option for this type of technology can serve as a mixed fabric, which has at least 50% polyester. The following types of fabric are perfect for this technology: satin, chiffon, blackout, gabardine, satin, deshain, oxford, charmus.

If we talk about knitwear, then the most successful options are ribana, prime, supplex, as well as felt, fleece, hockey net. Again, they take only their light shades so that the drawing is not distorted when printing or over time. Also in the textile industry, not so long ago, an innovation was presented - sandwich fabric, which is a two-layer fabric made of knitwear and featuring a unique weaving technology. The inner layer is natural cotton, the outer layer is polyester fibers.

Such material is used for sewing T-shirts, T-shirts, sweatshirts, the density can vary in many values.

The fabric wears well both in hot summers and in cool seasons. In terms of sublimation printing, it does not preclude making colorful and lasting designs.

Views

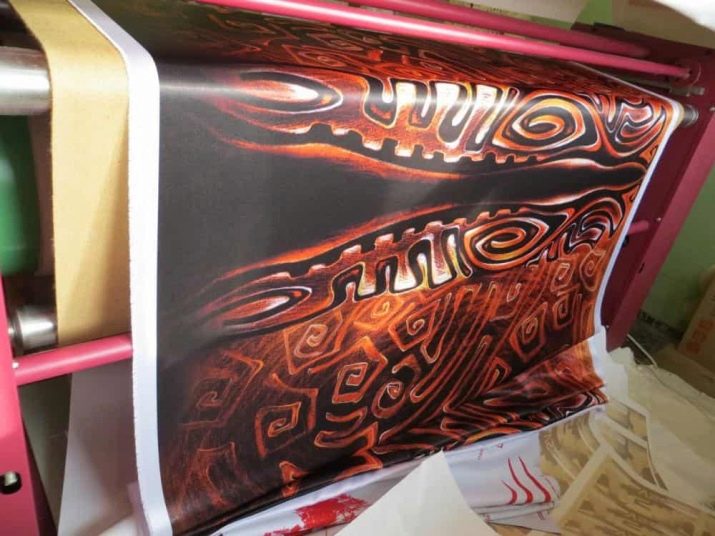

Specialists distinguish two types of sublimation printing: direct and indirect. In the first version, the paints are mixed and heated directly inside the sublimator, and then the drawing is transferred to the product. This is ideal for curtains, flags and wide woven fabrics in general.

There is also a wet technology of direct printing, when before work the fabric is treated with a primer (a kind of primer), and then a special printer with inkjet technology is used to apply the pattern. The dry method uses a laser printer and professional paper.

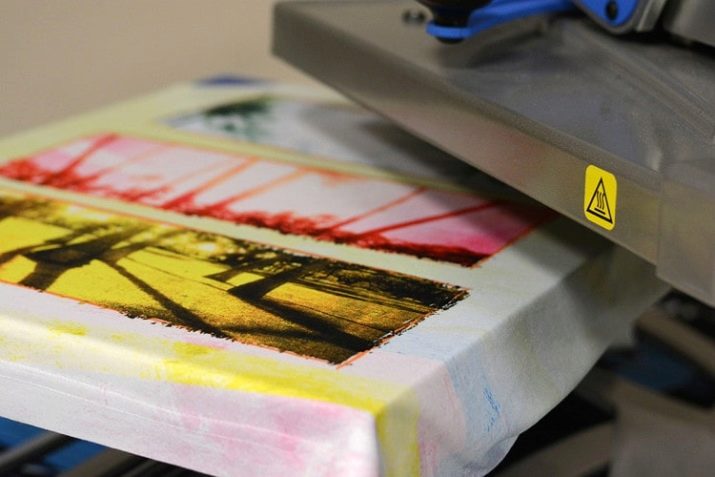

As for the indirect type of printing, it is called thermal transfer. This procedure consists of two stages: first, the mirrored image is drawn on siliconized paper, and then the image is transferred to the fabric using a heat press and special ink. Direct printing is used for industrial scale production, and indirect printing is used for piece production.

Equipment and materials

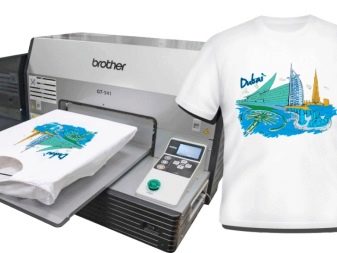

The first step for dye sublimation printing on fabric is a printer. Such equipment is offered to customers by more than one well-known brand: Canon, Mimaki, Mitsubishi, HP, Epson. There are several nuances that you need to pay attention to when choosing a printer:

- dimensions of the drawing (A4 format is suitable for small blanks, but A3 and A2 are needed for drawings on a large-format canvas);

- the presence of the possibility of continuous supply of ink;

- the number of colors (choose between 4 and 6 colors, while the first option is not often clogged, but the second provides the most natural color palette of the image).

The choice of ink is also influenced by what material you will apply them to, since the same dyes apply differently to the fabric and to the mug. Lomond ink brightens colors, but they give off a reddish tint, while InkTec products emphasize green.

As for paper, it also has its own nuances: for ceramics it would be better to use the Lomond brand, and for fabric - IST paper. It is important to consider all the specifics of the printer and ink.

The heat press is another essential component for sublimation printing. There are flat devices that are used to work with T-shirts, textiles, lace and plate (for printing unique patterns on ceramic items), baseball (for the production of a unique headdress and corporate logos).

Process description

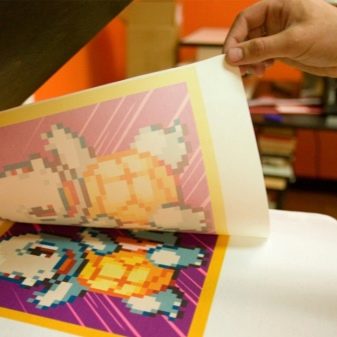

The technology of sublimation on fabric is that the design is first printed on sublimation paper, which is made in such a way that it does not absorb ink. Further, a high temperature acts on the ink, the pigment becomes gaseous and is transferred to the fabric laid out on the printer for a certain time.

The temperature required for sublimation on the fabric is based on the density of the fabric. Dark and colored polyester T-shirts need 170 degrees for 2 minutes. T-shirts with 50% cotton composition - 170 degrees and 140 seconds. Baseball caps - 160 degrees for 40 seconds. Atlas needs 180 degrees and an application time of 130 seconds.

How to do it at home?

In order to transfer your favorite drawing to fabric at home, you will need sublimation paper on which the image will be applied, a polyester product (50%) and an iron. Let's consider the nuances of the process.

- Cut the desired image from the sheet. It doesn't matter what size the field is. The main thing is that the drawing that you are going to transfer is intact.

- Make sure that the fabric is free of a variety of lint and debris.

- Place the picture face down on the fabric. It is important to consider the following: if the fabric is not very dense, then you need to put a sheet of paper under it so as not to stain the work surface or the back of the T-shirt. If the paper moves, you can glue it down gently.

- Heat the iron. Usually this is done up to the maximum temperature, but it must be borne in mind that devices are different. Place the iron over the image so that it completely covers it. You can press down on the device. Keep it for 45-60 seconds. If the area of the drawing is larger than the sole of the iron, the same must be done with the other part of the picture, the main thing is to follow the boundaries.

- Remove the iron and allow the workpiece to cool completely. The pattern is fixed while the paper is cooling.

- Make sure everything is cool and remove the paper from the fabric. Faint traces of the drawing will remain on the paper, and the image on the fabric will turn out to be bright and vivid.

You can wash the resulting product in a washing machine at a temperature of 30-40 degrees, and you need to iron it from the wrong side.

The sublimation method is a great alternative to buying printed T-shirts or sweatshirts from stores.

You can choose or even draw your own image, which, thanks to modern technology, will be transferred to the fabric.