Bath inserts: features, types and choices

A bath insert is most often purchased in cases where it is not possible to restore the old coating, and you do not want to take water procedures in a rusty container, risking flooding your neighbors. The features of the plastic inserts allow them to be placed directly on top of the old bowl of the sanitary fixture. At the same time, the bath is warmer, more comfortable and outwardly looks like new. But not only the aesthetic side of the matter matters, because a metal base leaking near the drain can lead to flooding of neighbors and even greater expenses.

How to choose an overlay and what should you consider when applying it? Will the liner completely replace a new bath or is it a temporary solution? How difficult is it to fit the insert correctly? An overview of reviews and a detailed analysis of all available options will help to understand these issues.

What is it and what is it for?

The bath insert is a finished product made of polymeric materials that completely repeats the size and shape of a standard range of plumbing fixtures. Such an insert allows for the restoration of the outer coating, replaces the worn out enamel. The use of liners on cast iron products with thick walls is especially important. During installation, the thin attachment part will not buckle and bend, there will be less risk of voids.

But for steel baths, the use of additional linings is not very suitable - too thin walls will give deformation loads, breaking a brittle polymer.

It should be taken into account right away that the insert is made of cast acrylic or composite material in standard shapes. If a bathtub with original parameters, purchased abroad, or simply non-standard in depth, height, width, shape is to be restored, the insert will most likely fail. The material of manufacture also matters. In addition to acrylic, there are vinyl and a combination of flexible industrial ABS plastic with an acrylic outer layer on the market.

The main purpose of the bath cover is to restore its presentable appearance and extend the service life of the product by several years. You should not count on its long-term use. With the estimated durability of acrylic at 20 years, the actual service life of the product barely exceeds 3-4 years.

Accordingly, the liner can be viewed as an inexpensive alternative to buying a new bathtub, allowing you to postpone larger expenses for a long time.

Advantages and disadvantages

Among the obvious advantages of bath inserts, the following are worth noting.

- Comfort level. It is much higher than that of any metal bathtubs, allowing you not to experience discomfort from contact with a cold surface. The bath heats up faster and provides a pleasant tactile sensation.

- Thermal conductivity. In this capacity, acrylic polymers are superior to their metal counterparts. The cooling rate of water does not exceed 1 degree in 30 minutes, respectively, taking a bath with the insert will be even more pleasant.

- Aesthetics. Acrylic bathtubs are considered to be one of the most beautiful ones. Their coating is always perfectly even and smooth, without defects or roughness. Even after applying the enamel, cast iron remains porous, and this property is clearly visible during operation. The pores intensively accumulate dirt and can become a place of accumulation of pathogenic microflora, mold and mildew.

- Minimum noise level. Polymers have higher sound absorption properties, so they can muffle audibility when a jet of water beats against the walls of the bathtub. This is important if you have to take water procedures in the evening or at night.

- High density. The lack of pores means that the material does not absorb dirt in the same way as its more porous counterparts. A soft sponge and a non-abrasive detergent are sufficient to remove plaque. You no longer need to scrub the bathtub for hours.

- Possibility of self-installation. With a minimum set of tools and a second person, even an owner with little experience can cope with the work.

In addition to the advantages, there are also disadvantages that complicate the operation of acrylic liners. The insert itself is much thinner than a conventional acrylic bathtub. and it retains its properties only partially. In addition, the product does not remain glossy and shiny for a very long time, its easy to scratch and even split... In multilayer products with a plastic backing, the lower part will inevitably become visible after some time due to wear of the decorative coating.

Varieties

All types of bath-to-bath repair inserts can be divided into several varieties.

- Cast, made of acrylic. The desired shape is given to them by heating and subsequent processing. The product turns out to be one-piece, with rather thick walls, uniform throughout its thickness. The manufacturing process is simplified as much as possible and excludes violation of geometric parameters. Such linings are quite durable, but more often they deform when they do not fit snugly against the base of the bath.

- Composite. They are molded from ABS resin, then finished with an acrylic layer to enhance aesthetics. The plastic liner is less susceptible to deformation, it is more elastic, but its service life is significantly shorter. In addition, the acrylic coating can wear off over time.

- Vinyl. The most fragile, rather slippery, but very aesthetic, with a pronounced glossy shine. Vinyl should be considered only as a temporary option, providing with its help the restoration of the bath for 1-2 years.

Obviously, each of the types of earbuds has its own advantages and disadvantages, but the main argument in most cases is the minimum price.

How to choose?

Among the most important parameters when choosing an insert, several can be distinguished.

- Coating color... If it is cast acrylic, it should be only white, without impurities and shades. The presence of gray, blue, pink tint indicates the use of low-grade components that do not meet quality standards. Such a polymer will crack rather quickly.

- Wall thickness... It is recommended to check it in the area of sideboards, where manufacturers traditionally save on materials. The standard is considered to be a thickness of 5-7 mm, but the larger it is, the less dangerous deforming loads will be. When pressed, acrylic can bend, but without hesitation and too much deformation.

- Material type... If the budget allows, it is better to give preference to cast acrylic. ABS plastic can be used where it is planned to change the bath soon enough and it is only necessary to close problem areas for a while.

- Defects. Sagging, damage, scratches, deformations are a sign of a violation of the production technology or storage rules. In any of these cases, discovered deficiencies can significantly affect the life and performance of the product. Slight irregularities are only permissible at the edges.

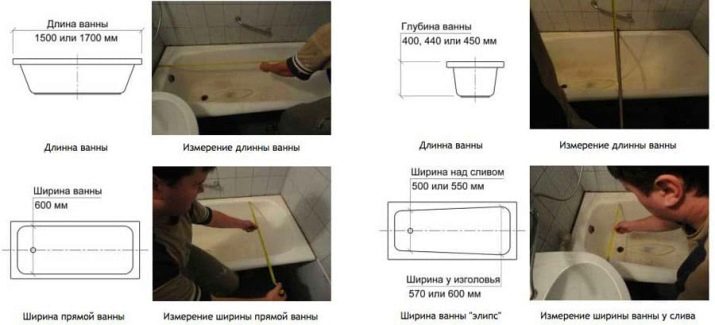

- Correspondence of sizes. If the insert is selected independently, it is worth pre-measuring all the individual parts inside and outside the bath bowl. The shape of the inner pallet must also be taken into account - it can be rounded or with rectangular edges.

All of these parameters can help in the selection of the correct liner for the restoration of the bath. A high-quality product will not create problems in installation and will serve for a long time.

How to insert?

The process of self-installation of the liner in the bath is not particularly difficult if you have the necessary tools at hand. But it is better to entrust the installation to professionals, otherwise in the process of work an expensive tab may be accidentally damaged. The liner installation process can be divided into the following stages.

- Bath preparation. Its surface is cleaned of dirt, the trim is removed from the side (you can skip it if there is a free edge of at least 10 mm). All traces of sealants, cement, and other building compounds must be carefully removed. The bowl itself is treated with acidic compounds, defatted with baking soda. Next, you need to dry the coating and remove all traces of household chemicals. This method allows you to do without completely removing the enamel with a grinding wheel.

- Dismantling of drain fittings. It is worth considering that the drain and overflow will most likely have to be bought again, taking into account the changed dimensions and wall thickness. When installing the product by the master, the siphon is often included in the kit.

- Liner preparation. First, he tries on the bathtub for marking work. It is important to make sure that all elements fit snugly together. Technological holes are outlined (you need to cut them yourself), edges are cut that protrude beyond the sides. The liner is quite large, it is better to load and unload it from the bath after trying it on together.

- Cutting technological holes. It is necessary to saw off the edges and cut out rounded holes in the bottom and on one of the sides to install the drain fittings. Circular cutting is performed using special crowns. It is recommended to use special blades and files for plastic, which are less damaging to acrylic. But in general, the sides can be cut even with a standard hacksaw for metal.

- Sealant and foam application. Fastening of the acrylic insert is carried out using special foam with a two-component structure. Conventional building compounds are not suitable for these purposes.In addition, the drain and overflow holes must be carefully treated with silicone sealant in a circle in several layers - this is necessary so that water does not penetrate between the walls of the bath and the liner. The foam is applied with a lattice along the bottom, sides, edges of the bowl, with a step between stripes of about 10 cm.

- Installing the liner. It is made quickly, until the polymerization foam has polymerized - there is about 15 minutes for everything. It is important to place the liner evenly, joining the technological holes, and firmly press it against the bath over the entire area. Next, a siphon and an overflow are mounted, the bath is filled with water to ensure the required pressure on the surface of the material. The polymerization period of the foam is individual - you can find it out from the information on the package.

- Sealing joints. While the liner and the bath are glued together with foam, you can start sealing the joints that have arisen around the perimeter. For this, a silicone-based sealant with a transparent or matte white structure is used. Further, the perimeter of the bath is decorated with a decorative border.

Once the polymerization process is complete, you can drain the water and use the bathroom as usual.

Review overview

The opinions of buyers about bath inserts can be called quite contradictory. Undoubtedly, all consumers note the striking external changes in the appearance of her bowl. It looks quite aesthetically pleasing, the liner completely covers all previous damage and makes the plumbing fixture truly updated. But the joy often turns out to be short-lived and the reasons for this are a violation of the installation technology, low quality of the product, and even non-observance of the operating rules.

Among the positive aspects, the warm surface of the acrylic coating is noted - it is much more comfortable than cold metal. In addition, the price of the insert costs about half the cost of a new bath, it is less laborious in installation, and allows you to carry out all the work within 1 day. This method of restoring old bathtubs avoids peeling paint from the surface and looks quite attractive in general. Caring for such a coating is also simplified as much as possible and comes down to cleaning with mild compounds without abrasive particles in the form of detergent or liquid soap.

There are also many disadvantages to bath liners. It is noted that they slippery and not too safeespecially for the elderly. In case of a poor-quality installation, a gap is formed between the sides of the old bathtub and the new liner, leaving the feeling that a person is sitting "in a basin". In addition, if water systematically gets between layers of 2 different materials, it will inevitably begin to "bloom", exuding an unpleasant odor.

Thin acrylic liners are not resistant to shock loads - even dropping a shampoo bottle to the bottom of the bath can lead to cracking of the material, not to mention the claws of pets.

For information on how to install the acrylic insert in the bath, see the following video.