Trouser hemming tape

There are several ways to hem the trousers - give it to the professionals in the atelier, or complete the task yourself with the help of threads and a needle. However, the first method can be expensive and the second time-consuming, so more and more people decide to use the special tape.

What it is?

Pant hemming tape, also called trouser tape, is designed to shorten the bottom of the leg to protect the fold from abrasion and warping. Frankly, there are two varieties of it, the first of which, in general, is devoid of an adhesive layer, but most often it is about the second - a sticky cobweb. The ease of use of the duct tape makes it suitable even for those who cannot sew. Such a piece of cobweb allows you to very quickly change the length of the pants, without even leaving visible seams. It is customary to purchase it by footage in the hardware departments.

It is recommended to clean things with adhesive tape in a washing machine at a temperature of less than 60 degrees, or in dry cleaning.

Views

It is possible to tidy up the trousers with the help of two types of trouser ribbons.

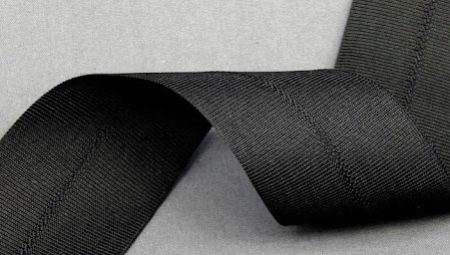

Reps tape

Rep ribbons, also known as braids, are made from cotton and very durable polyester. The presence of flax and wool is also possible, which does not cause irritation even on sensitive skin. It is intended for processing trousers, sewn from materials with a thickness above average. By folding the bottom of the legs and fixing it with a tape, you can increase the wear resistance of the product, as well as protect its edges from rapid deformation. The width of the cut, slightly thickened along one edge, is about 15 millimeters.It is necessary to sew on a rep tape on a typewriter, which takes a certain amount of time, but this method allows for greater strength. As a result, the trousers are not afraid of regular washings, and the braid itself, without shedding or rubbing, serves for a long time.

Iron-on adhesive tape

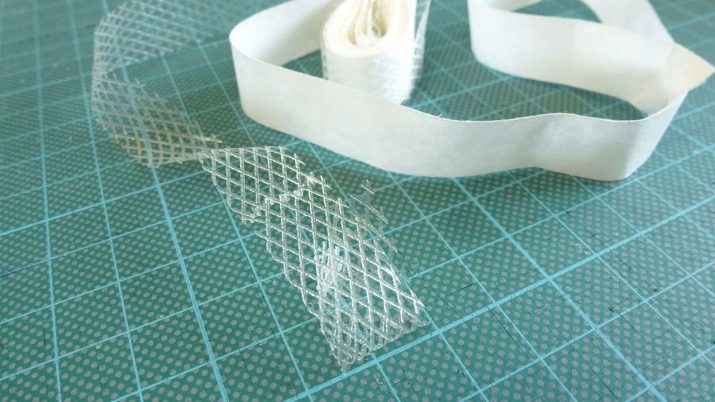

A sticky spider web with an adhesive base is much more popular. The translucent adhesive tape is made of polyamide that can easily withstand hand washing and does not contain any chemicals or any toxic substances. A piece of non-woven fabric is covered with an adhesive in production. For hemming trousers, a double-sided version is most often used, available in white and black shades. A spider web 10, 15 or 20 millimeters wide is fixed with a hot iron and steam.

It is sold in rolls and packaged sachets of 3-5 meters, it has a very budgetary cost.

To hem suit trousers from a thicker fabric, you will need to use a hot-melt mesh - that is, the same cobweb, but of greater rigidity. Such a tape has a paper backing on one side, which is removed before the allowance is applied. Its width varies from 0.5 to 5 centimeters. In general, the thickness of all types of cobweb can range from 0.17 to 0.25 millimeters, and the width can be from 5 to 70 millimeters.

It should be noted that adhesive tape is not recommended for use on finely textured fabrics, as this may impart unnecessary stiffness to the tape. And also the spider web is not suitable for jeans and dense fabrics due to the fact that it peels off over time, as well as for expensive products that can deform after processing.

How do I work with the ribbon?

Correctly using a trouser tape is not too difficult. You can determine the required amount of material right in the store. To do this, the lower part of the trousers is straightened on a flat surface, and the width of one leg is measured. Then the resulting number is multiplied by 2 to get the length of the tape for one leg, and then - again by 2 to understand how much it will take to process both legs. Some experts, however, add 2-3 centimeters to the doubled leg width.

If the tape is purchased several centimeters longer than the result obtained, then on a small piece it will be possible to test the new technology.

The length to which the pants are folded is determined by eye, or with a reference point to the middle of the heel. The fitting is carried out either in shoes or without them, but always with a belt if a person constantly wears it. If the pants are worn on bare feet, then their bottom edge should reach floor level. The correct length is secured with pins in the area of the crotch and side seams after folding the legs to the right side. It is important that after trying on and marking the gap from the waist to the line along the main seams coincide on both legs.

It should be mentioned that the correct length is determined only if the model is completely immobile. If you need to hem your own trousers yourself, it is better to use a sample in the form of old, most successfully cropped trousers.

When processing dense products, in principle, it is not scary if the color of the braid does not match the color of the fabric, however, for thin summer trousers, you will need to purchase a white spider web. If the store only has narrow adhesive tape, then you can arrange it in two rows next to each other.

Finally, it is worth mentioning that although the cobweb allows you to get a beautiful, even cut, processing with its help is considered less reliable than in the case of hemming with threads.

It is quite simple to hem using rep tape. First, both the clothes and the braid itself, purchased in the same color as the trousers, will need to be ironed, including so that the finishing material shrinks. Another option involves pre-soaking the trouser tape in hot water and further drying. You will also have to prepare threads: contrasting, intended for sewing, as well as in tone, necessary for hemming. The work will be carried out on a sewing machine fitted with suitable needles.

After processing the edge of the trousers, the pants are turned inside out. After trying on them, by this time there should be a line indicating the required length and applied either with soap or chalk. The braid is applied to this line with its thickening upwards so that its end edge extends 1.5 centimeters beyond the step seam. In order to avoid movement of the tape, it is fixed on the trousers with pins. The tape is hemmed with a needle and thread of a contrasting color so that the line is placed in the middle.

In the area of the crotch seam, the remaining end of the tape is folded over and the fold is marked. Further, the leg is processed on a sewing machine with two lines: the first - next to the thickening of the tape and the second - on the opposite side. Another seam is made at the seam of the tape. Turned inside-out leg allowances are swept in so that 2-3 mm of tape protrudes from under the bottom of the trousers. Upon completion, the hemming is carried out manually with a blind stitch or on a machine with the function of "blind stitch". Everything ends with the processing of the bottom with an iron through a damp cloth.

To glue a standard spider web, you need to bend the bottom of the leg so that you get a fabric pocket. Then both sides of it are connected to each other by gluing to the tape on both sides. It is important that the tape runs along the edge of the seam allowance, but does not protrude from behind it. In order for the adhesive to melt, it is necessary to iron the fabric to the nonwoven material, preheating the iron to a sufficiently high temperature. If it was not possible to stick the tape, then you need to lightly sprinkle it with water, and repeat the ironing again.

Before starting work, you will need to prepare a number of tools. A centimeter will allow you to measure the required length of the product, and a ruler with chalk or a piece of soap will make it possible to make markings. With the help of scissors, the excess cobweb is cut off, and the fabric itself, and the sticky substance melts with an iron. It will be most convenient to work on an ironing board. It is also worth preparing a piece of cotton cloth or gauze for the safety of processing.

A number of masters advise to pre-clean the pants themselves and the cobweb from the smallest particles of debris, which can make the fixation less reliable, and also carry out decating. The essence of the procedure is that the fabric is sent to the washing machine for 1 wash cycle. If there is no opportunity to wash the material, then it is processed with steam using an iron or steam generator. Decatting promotes shrinkage of the fibers, which, in turn, prevents deformation of the product during wear. This is especially true in the case of clothing made from natural materials, such as cotton or linen.

It is even easier to interact with a mesh cobweb equipped with a paper layer. After the markings have been applied to the leg, you will need to put the adhesive tape on the wrong side with the paper up and carefully glue it until it is fixed on the fabric. Next, the paper layer is carefully removed and the next part is applied to the exposed sticky part. To fix it, you will already need to use an iron.

If the cobweb does not lie evenly, or the trousers require re-stitching, then the adhesive material can be removed without any problems on its own. The first method suggests carefully, without touching the product, to process the gluing site with the steam of the iron or with a hairdryer set to the hottest setting for 2-3 minutes.After the adhesive tape has been carefully peeled off the legs, a piece of cotton is placed in its place. The pants are ironed with a steam function, as a result of which the remaining substance is absorbed into the fabric pad. Remaining glue will go away after washing.

And you can also cope with the problem with the help of 70% or 90% medical alcohol. A cotton pad is impregnated with liquid, and with its help the place with glue is smeared. After 5 minutes, the tape should come off the garment. To remove stubborn glue, you will need to hold the soaked cotton swab on the fabric for a few minutes. So that an unpleasant smell does not remain from the alcohol solution, the cleaned thing must be rinsed.

Another effective way is to use vegetable oil. The substance is abundantly impregnated with cotton wool, which is then applied to the junction of the glue and fabric. After a couple of minutes, you can carefully peel off the tape. In principle, it is not forbidden to use a solvent, acetone or turpentine.

However, interaction with these liquids should be very careful and only take place with the protection of hands and respiratory organs.

If there is sticky material on the sole of the iron, it can be removed with a piece of sandpaper. This method is suitable, however, only for products whose durable material is not covered with scratches after intense mechanical stress. It will also help the use of a special cleaning pencil or a liquid product that gently cleanses dirt from the cooled sole with a sponge. Finally, you can use a simple cotton cut: heat the contaminated iron to + 30 ... 50 degrees and "wipe" the required area on the fabric by ironing.