How to insert a needle into a sewing machine?

The ability to sew clothes yourself, repair and alter finished products arouses great interest in sewing machines. In addition to buying such equipment, it is necessary to master the basic principles of its operation, be able to establish the sewing process, and also cope with breakdowns. One of the most common troubles that happen to inexperienced seamstresses is the breakdown of the game, so it needs to be replaced. To find the right needle and put it in accordance with the rules and regulations, you need to know what to look for and what the replacement procedure is.

Features of replacing needles on different types of typewriters

Sewing machines can be home and industrial. In addition to the name, they differ in size, number of functions and structure. It is necessary to select the correct needle for each device, otherwise the machine will not work well or will not sew at all. The choice of needle should be made depending on the equipment, the thickness of the fabric and the thread to be used. Despite the differences, the structure of sewing machine needles is the same, namely:

- eyelet, the hole through which the thread is threaded - it can turn into a groove of different lengths: short and long;

- kernel - the main part of the needle;

- the top of the needle, having a flat part on one side - a flat.

The construction of home sewing machines may also differ depending on the model. To change a needle on a specific piece of equipment, you need to know how to properly fit a new part instead of an old one. An assistant in this case can be the type of equipment seam and the model of the machine itself.For straight stitch machines, thread from left to right; for zigzag equipment, thread from the front to help determine where the flat side is at the base of the needle. To insert a needle into a manual Podolsk machine, you need to raise the needle bar to its highest position and install a new part so that its flat part is on the right.

When replacing the needles, it is important to insert them all the way so that during operation it does not fall out and break. For full fixation of the needle, a special screw is provided, which securely fixes it in its place. If everything was installed correctly, then during the operation of the machine the seam will be smooth and beautiful.

Several manufacturers have developed their own technique for replacing needles. So, Brother equips its equipment with a special screwdriver, which allows you to unscrew the old and put in a new needle, its flat part will be located away from itself.

To tighten the new part, you should use a screwdriver that will grip the screw well. If, after repair work, there are malfunctions in the operation of the sewing equipment, it is worthwhile to read the instructions again and check the correct installation of the new needle.

Step by step description of the process

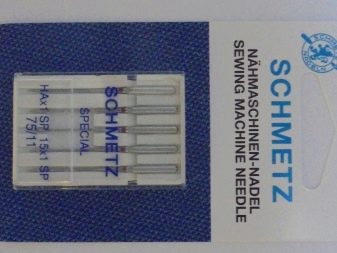

To achieve a high-quality sewing machine, an even seam, without skipping stitches, it is important to choose the right needles for certain equipment. There are a large number of options, so it is important to look at the labeling, namely:

- the standard version, which is suitable for most machines and overlocks, is designated HAx1 or 130 / 705Н;

- when choosing a needle for a coverstitch machine or overlocker, you should give preference to products labeled HAx1SP or ELx705.

In addition to choosing needles for a particular machine, you need to pay attention to the type of fabric. For silk, you need to take a needle with the number 60/6, where 60 is the size of the needle, and 6 is the diameter of its shaft. For the finest materials, products with numbers from 60/8 to 80/12 can be used.

For linen and knitted fabrics, specialized threads and needles with numbers from 80/12 to 100/16 are selected. If you have to work with coarse and dense materials, then the work is carried out using thick threads and a needle with a number from 100/16 to 120/19.

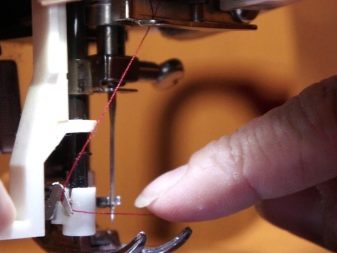

After the correct needle has been selected, you need to install it in the machine so that the device does not cause any problems and the quality of the product is as good as possible. It is not difficult to insert a new part into a sewing machine if you adhere to the following work procedure:

- with the flywheel, it is necessary to set the needle to the highest position;

- the foot should be lowered;

- the left hand should hold the needle, and the right hand should loosen the screw that holds it;

- remove the needle from the needle bar;

- the new needle must be in the same position as the previous one, since this is the correct option for the specific equipment;

- with your left hand you need to hold the new part, and with your right hand you need to fix it with a screw.

The positioning of the needle in the needle bar can be different, the flat side can be turned right and left, forward and backward relative to the seam. Each manufacturer indicates the correct position of the needle in the device.

Adjusting the size and thickness will be necessary when sewing with different fabrics and threads. In some cases, it is necessary to install a twin needle when sewing with a zigzag stitch. When everything is ready to start work, all that remains is to thread the thread and start the sewing process.

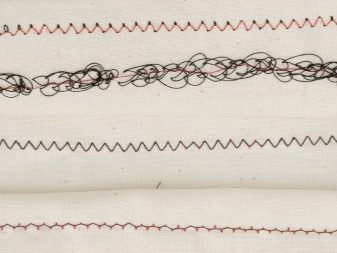

Checking the quality of the installation

To find out how correctly the work on replacing the needle in the sewing machine was carried out, it is necessary to make a test seam. For work, you should take a small unnecessary piece of material and test the machine on it. If the seam came out ugly, with obvious irregularities, skipped stitches, different stitch lengths, then the needle was installed incorrectly. If on the sewn fabric there is an even seam, without flaws and inaccuracies, then nothing needs to be changed, since the work was completed successfully.

It is impossible to leave an incorrectly installed needle in the machine, since you can not only spoil the fabric or product that is being sewn, but also break the needle or disable the machine itself. In order to prevent negative consequences, it is important to immediately change the position of the needle, namely:

- the machine is completely disconnected from electricity;

- the screw is loosened by hand or with a screwdriver, the needle is set in the correct position;

- if the thread starts to break during the quality check of the work, then it is necessary to correct the position of the needle by turning it slightly in one direction or another;

- when the needle is in place, tighten the screw;

- once again check the quality of the work done.

Important! It will be necessary to adjust the position of the needle until the seam is perfectly even and beautiful.

Consequences of incorrect installation

Each manufacturer makes the shape and size of a needle for a specific sewing machine; the flat side of the base of this product also differs from company to company. All this is done in order to provide a more reliable fixation and optimal position of the needle in the needle holder. If you put in the wrong needle or position it incorrectly, the hook will not catch the thread, which will result in a missing stitch, as it will not be able to form.

If the needle is incorrectly replaced, it will not be possible to obtain a high-quality seam, the threads will get tangled, not all stitches will be sewn, which will damage the product being worked on. In addition, due to the incorrect position of the needle, it will not always fall into the hole, from time to time bumping into the throat plate, which will entail the formation of potholes and irregularities that will deform thin and delicate fabrics during operation. Another unpleasant outcome can be breakage of a needle that cannot withstand constant collisions with the plate... The hook of the machine can also be damaged if the tip of the needle breaks and falls into it during operation, so it is important to correctly replace this element, avoiding such consequences.

How often do you need to change?

In the process of studying the structure of a sewing machine, its operation and troubleshooting, it is difficult for beginners to find an answer to the question of how often a needle in equipment needs to be changed. If you can figure out the replacement procedure itself and find the right position, guided by the manufacturer's tips or by making your observations and searching for the optimal position, but figuring out when to replace the existing needle is not always clear.

Among the most objective reasons why it is necessary to remove the old needle and put a new one, the following can be distinguished:

- breakage of an old part;

- change in shape, bending;

- dullness of the tip;

- depending on the thickness of the fabric and threads;

- with frequent damage to the thread with a needle.

Manufacturers do not provide clear guidelines on how often the needle should be replaced because the main factor is the quality of the seam produced by it. If there are no complaints about the work, the seam is smooth, then there is no reason to replace the needle. Most often, it is necessary to change this part because of the different thickness and type of material with which it is supposed to work even after changes in its characteristics. If a bent or dull needle is not replaced in time, it can not only spoil the product that was being worked on, but also harm the sewing machine itself.

Important! To avoid any problems with the operation of sewing equipment, it is necessary to buy only high-quality parts and install them correctly. By making timely maintenance and replacing worn-out parts, it is possible to operate the machine for a long time and get excellent results on it.

For information on how to insert a needle into a sewing machine, see the next video.