All About Reflective Fabric

Reflective clothing and accessories were invented to improve the safety of employees and workers in hazardous areas and industries. Among them are such specialties as miners, road workers, medical workers and police officers. Recently, reflective fiber has become a fashion trend in everyday wear among young people and athletes.

general description

The textile industry produces a variety of reflective fabrics that are designed for narrow special applications or for everyday wear. The ability to reflect light falling on it is an additional layer of protection. The use of materials capable of returning the light from headlights, spotlights or lanterns to them serves to ensure better visibility of people in the dark. So, in road conditions, the driver will quickly notice a pedestrian or an athlete doing an evening run, a cyclist or a motorist fixing a problem in the motor.

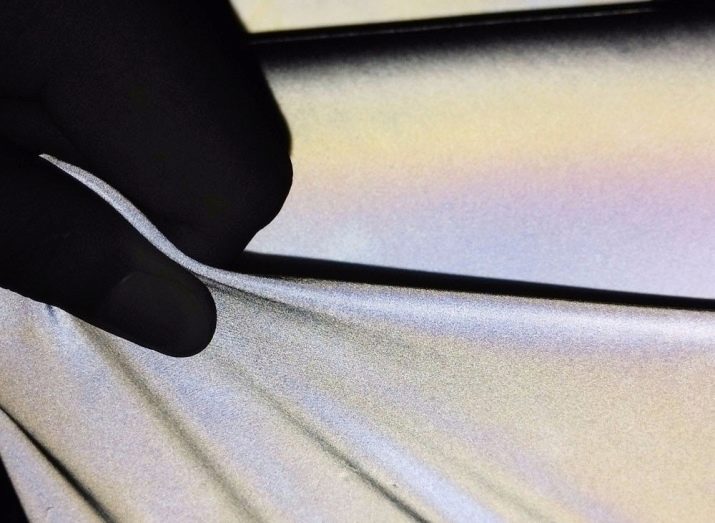

The reflection of light by the fabrics from which the clothes are sewn occurs due to the coating of the surface with special compounds. The tissues interact with the rays of artificial light falling on it in different ways, therefore there are several types of materials. Some of them are made using the method of cubic prisms, from the edges of which the rays falling on them are reflected in turn.

Others are made using wide-angle glass microscopic lenses, which are coated with a silicone varnish on top to prevent mechanical stress.

Views

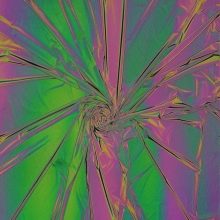

The reflective qualities of the material depend on the type of reflective coating. From the total volume of reflective fabrics, three main groups can be distinguished, which differ in the ways of reflection of directed rays:

- mirror: reflects incoming light from a directional artificial source;

- diffuse: much less light returns to the spotlight than was directed at the reflective object;

- reflective: Application of a range of mirrored surfaces at an angle of 180 degrees, which produces a significant glow effect on the fabric.

Qualitative differences in the methods of reflection of light rays are due to the use of various components and completing compositions for the manufacture of all clothing or luminous inserts.

Most often, fabrics that reflect light are gray, and when the directional beam of the lighting device hits the material, the material receives a white reflective backlight. Fabrics with a reflective gray effect are versatile, as they go well with any other color. Inserts of gray fragments are suitable for any style and purpose of clothing, and also contribute to obtaining more brightness when reflecting rays.

Basically, three types of materials are used as a basis for applying special compositions. One of them is polyester, which has a low density, but has maximum flexibility when applied to a reflective layer. The cost of a polyester-based fabric is relatively low, and it is sold in rolls about 1 meter wide.

The base, made of polyester with added cotton, is denser than the previous one. The fields of application of the blended fabric are very diverse. The material, which is 100% cotton, needs special impregnation, as it is used for specific tasks. The impregnating compound has fire-fighting properties and is intended for workwear for workers in fire-hazardous industries and firefighters.

All kinds of reflective fabrics can be divided according to the degree of brightness, the coefficient of which is measured in Candela. Materials made on the basis of gray are characterized by a maximum brightness level - from 300 to 500 Candelas. Brightness is largely dependent on the shade of the microscopic glass beads that make up the reflective layer.

The industry also produces reflective fabrics based on other colors, but their brightness values are far behind their gray counterparts and range from 70 to 125 Candela. They are used for decorative or advertising purposes.

Particular attention in the production and use of reflective materials is paid to their resistance to abrasion during operation, cleaning and washing. The most practical was the fabric based on 100% polyester. Clothes made from it greatly increase the visibility of a person in the dark and can withstand about 50 machine washes without changing the reflective effect. During transportation and long-term storage in a warehouse, special polyester clothing does not wrinkle and does not lose its qualities.

Applications

Reflective fabrics are widely used for the manufacture of various sports attributes, including stripes, signs on the form, various signal and decorative inserts. Fashionable materials are widely used for decorating and sewing accessories. Sewing brands in many countries use reflective fabrics for clothing and footwear.

Practical fabrics with a reflective effect are used for sewing special protective clothing that meets the necessary requirements for functionality, comfort and aesthetic appearance. All useful parameters are taken into account when creating suits and accessories for workers of professions associated with work at night or in poorly lit places. In addition to work suits, overalls, jackets, robes, aprons, separate vests, arm ruffles, shoes and other necessary equipment are made from light-reflecting fabrics.

The nuances of the development and production of special clothing are associated with industry characteristics.So, the fabric must be waterproof, and also not wrinkle or absorb dirt. The material should not lose its qualities if frequent disinfection is required, as in the case of medical workers.

Modern work clothes must meet criteria such as the individuality of the corporate style and reliable comprehensive protection against harmful production conditions.

To reliably protect the interior of the house, located on the sunny side, a reflective coating for roller blinds has been developed. Thanks to such simple protection, a comfortable atmosphere is created in the apartments, and the owners can save significant money on the purchase and operation of an air conditioner. At the same time, curtains with aluminum spraying do not block the view from the window to the residents who are inside, but are completely opaque to the outside view.

Care rules

Reflective clothing or items with reflective fabric inserts do not require special maintenance. However, there are several recommendations that allow you to maintain its main distinctive properties throughout the entire service life.... In this case, you should choose the right detergent for washing, avoiding alkaline or bleaching agents. The washing process should be soft and gentle so that reflective elements are less exposed to mechanical abrasion. When drying such clothes, do not wring them out too much. You need to hang the item to drain water at moderate temperatures.