All about fabric density

Predictably, when purchasing this or that material, as well as products from fabrics, the overwhelming majority of buyers are interested in their quality. Here it is worth focusing on the key characteristics, and therefore it is recommended to know everything about the density of the fabric. The corresponding indicator becomes one of the key criteria for choosing any things. However, most often, density is focused on when buying bed linen or the material for making it.

What it is?

The density of a tissue is understood as the weight of a fragment of a certain area. In the overwhelming majority of cases, this indicator is expressed in grams per square meter of canvas, that is, in g / m2. This means that the density directly affects the amount of raw materials used in the manufacture of the fabric, as well as its strength. On the modern market there are samples of bed linen made of material with a density in the range from 75 to 150 g / m2. However, it is recommended to give preference to fabrics with indicators of at least 100.

In the process of choosing a canvas or ready-made products, many buyers, not having information about the density, try to assess the quality and even the potential service life by touch. It is important to take into account that the described parameter determines the key performance characteristics of the fabric, namely:

- strength;

- wear resistance;

- durability;

- hygiene (inverse relationship);

- hygroscopicity;

- ventilation (inverse relationship).

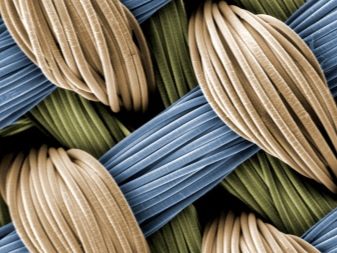

The density itself is the number of threads of both warp and weft, which fall on 10 square meters. see canvases. It should be noted that there are two corresponding meanings. To understand the features of the density of a material, it is necessary to highlight key concepts.

- Absolute density - the actual number of fibers within sq. see canvases. It should be remembered that in the same area of large-diameter threads there may be noticeably fewer threads, but they will be located more densely. On the other hand, more fine filaments will be placed at significant intervals.

- Maximum rate - the limiting number of threads that fit in one square. see It is important to take into account that they are all the same diameter and are located without shifts, at equal intervals.

- Relative density - the ratio of the maximum and actual values, reflected, of course, as a percentage.

In addition to everything already listed, it is important to focus on two types of density, namely:

- linear;

- superficial.

In the first case, we are talking about the already mentioned number of threads, which, according to world standards, is measured in "Thread Counts" (TC). The most popular fabrics have the following linear indicators:

- cambric - low density (from 50 to 75 TC);

- coarse calico - value below average (from 80 to 100 vehicles);

- flax - medium density (from 120 to 140 TS);

- poplin and ranforce - above average (from 160 to 200 vehicles);

- percale and satin - high density (from 200 to 300 TC);

- jacquard is a very high figure (from 320 to 700 TS).

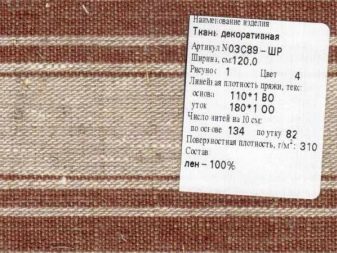

Surface density is exactly the parameter that is indicated on the price tags. It is measured in the already mentioned g / m2, and is determined by the formula: P = m / L * B. Here m is the mass, and L and B are the length and width of the fabric, that is, to find the desired indicator, the mass is divided by the area.

It is worth noting that this is the key parameter and is regulated by the current GOST.

How to determine?

Today, the simplest and most affordable way to check the density of a particular fabric is visual counting of threads. In this case, an ordinary magnifying glass will be a device for determining the required indicators. Another method to find out the characteristics of a material in order to understand how suitable it is is to use a projector. In this case, the device, due to a system of lenses and mirrors, displays a multiply enlarged image of a fragment of the canvas on the screen with appropriate divisions.

It is worth noting that both of these methods for calculating tissue density, despite the significant differences, will require significant time costs. It will be much easier to use special kits, which include:

- digital scales with a measurement step of 0.01 g, the main characteristic of which is increased accuracy;

- weight for calibrating the measuring device;

- circular cutter designed for cutting out circles of the test material with an area of 1 square decimeter;

- area for cutting samples.

To calculate the surface density, you will need:

- cut out a sample in the form of a circle using the above-mentioned device;

- weigh a piece of tissue on an electronic scale;

- the resulting parameter is multiplied by 100.

The calculation of the described value can be made according to the formula: MSp = (To * Po + Tu * Pu) * 0.01. Here To and Tu are linear indicators measured in tex, warp and weft fibers, respectively, Po and Pu are the number of threads per 100 mm of fabric.

Indicators for different types of fabric

To compare the key characteristics of materials made from fibers of different thicknesses, concepts such as relative and maximum density were introduced. And in this case we are talking not only about fabrics for curtains, tulle and bed linen. For example, the density of classic denim is 13 to 14.5 ounces per square yard. Indicators of heavier species reach 15.5.

If we consider the most dense materials, then it is worth mentioning banner fabric. We are talking about a modern advertising medium, the density of which directly determines the scope of its application. The standard density of material for outdoor and indoor advertising is 280, 340, as well as 440 and 510 g / sq. m.

Satin

One of the key features in this case is the use of twill type weaving, which provides for double twisting. This approach provides the smoothest possible surface. In addition, the material is characterized by good density and gloss.

The seamy surface of satin is more dull. It can pile and sometimes feel like flannel. Standard satin has weights ranging from 115 to 120 g / m2. The material of the De Luxe class is made using active dyeing, which increases the analyzed indicator. In this case, the latter reaches 130 g / m2.

Satin Jacquard

This material has a relief pattern, which is the result of a special weave of fibers. Today, jacquard is used to create products belonging to the elite class. Such things are characterized by:

- maximum softness;

- lack of electrification;

- intensive absorption of moisture;

- presentable appearance.

The density of jacquard fabrics ranges from 135 to 140 g / m2. It should be borne in mind that it wrinkles a lot.

It is necessary to iron it half-wet and from the reverse (seamy) side.

Calico

In accordance with the GOST standards that are current in the Russian Federation, we are talking about 100% cotton. Such underwear sets are in record demand these days. A feature of the material is the weaving of large-diameter plain weaves. Depending on the thickness of the fibers, coarse calico is distinguished with the following density classes:

- low - 80 g / m2;

- medium - from 90 to 100 g / m2;

- good (most popular) - from 110 to 125 g / m2;

- high - from 130 to 160 g / m2.

The latter type of fabric is now less common. This is due to the comparative stiffness of the web, which is the result of multiple fractures at the intersections of the fibers.

Poplin

Plain weaving is also used in the production of this material. However, unlike coarse calico, threads of different thicknesses are used here. Small scars on the surface are formed due to the fact that thinner fibers act as a base, and a larger thread is taken for the weft. Another important difference is the greater curl, which in turn provides softness.

The average density of poplin ranges from 110 to 120 g / m2. It is worth noting that the fabric itself and, accordingly, products made from it are slightly more expensive than coarse calico.

As practice shows, the best choice in the overwhelming majority of cases is the material of domestic production, which is characterized by quality and increased density compared to many foreign analogues.

Tencel

In this case, we are talking about a silky material that is produced using advanced technologies. In this case, the raw material is high-quality cellulose (in the overwhelming majority of cases, eucalyptus is used). We are talking about the most environmentally friendly material that is soft and hypoallergenic and has a bacteriostatic effect.

A high-quality tencel is able to adapt to a certain temperature, and also absorbs moisture well and allows air to pass through. However, it should be borne in mind that when wet, the material can noticeably deform (sit down or, conversely, stretch). Taking into account all the characteristics, the fabric should be protected from direct UV rays, washed exclusively with liquid detergents (dry cleaning is recommended) and ironed only on the back side. The density of tencel and mixed fabrics ranges from 120 to 130 g / m2.

Linen

Linen can be deservedly called one of the most environmentally friendly. Such an assessment will be most relevant for things made of unpainted fabric.

It should be noted that, in comparison with cotton, flax is less whimsical, and therefore its cultivation does not require the use of pesticides.

In this case, the natural color for the fabric is gray-beige, and shades of "ivory" are also possible.

A good indicator of the density of linen material is considered to be the range from 125 to 150 g / sq. m. But it is important to take into account that such a fabric quickly deforms (crumples) and is relatively difficult to smooth out. It is also quite tough to the touch when compared to cotton linens. By the way, blended samples of fabrics, in which the proportions of linen and cotton are 30 and 70%, respectively, are very popular.

Ranfors

In this case, we are talking about 100% cotton with a basis weight of 120 g / m2. This fabric belongs to the premium segment, and high quality yarns are used for its production. The key competitive advantages of Ranfors coarse calico include durability, strength, and increased linear density. It is worth noting that this fabric in the production process is treated with alkaline solutions, which provide it, in addition to wear resistance, smoothness and hygroscopicity.

Biomatin

The fabric, which is based on cotton, is made from threads impregnated with hypoallergenic drugs using a special technology. The density of biomatin does not exceed 130 g / m2. At the same time, the fabric is in many ways similar to calico, which belongs to the premium segment.

Bamboo

At the moment, this fabric is becoming more and more popular in Russia. It is made from bamboo mass using modern technologies, which determines the appropriate characteristics. Quite soft and pleasant to the touch, it has a density of at least 90 g / m2.

Silk

Legendary fabric originally from the "Celestial Empire". However, it should be noted that today the highest quality samples of the material are the result of manual labor and are produced in the "Land of the Rising Sun". It is noteworthy that the unit for measuring the density of silk fabrics is Mommi, and it is denoted mm. Indicators range from 6 to 30 mm.

Mako

This is a material that originated in Egypt. The described indicator in this case is 220 g / m2. This fabric looks very similar to silk, and manufacturers use the so-called reactive printing to print on it. It is quite gentle to the touch and stretches well.

Percale

Outwardly, this fabric looks like poplin, while its outer part is noticeably brighter than the inner one. The material made from long-staple cotton using plain weave is characterized by increased wear resistance, shine and smoothness. Percale was originally a 100% cotton fabric, but over time, manufacturers began to add polyester, polyester and silk. The density of the material ranges from 100 to 160 threads per square centimeter of fabric.

Other

In addition to all the fabrics already considered, it is worth paying attention to a number of other popular materials. For example, the lightest fabric used for the manufacture of jackets should be highlighted. This refers to the material called Duspo. Its density ranges from 80 to 90 g / m2. In the same context, it is appropriate to mention also the lining fabric. It, in turn, is divided into three categories, taking into account the described indicator:

- light - up to 90 g / m2;

- medium - 90-100 g / m2;

- heavy - from 111 g / m2.

In addition to all the fabrics considered, cambric and satin are popular, the density of which is 20-30 and about 240 g / m2, respectively.