Features of polycotton fabric

Polycotton appeared on the Russian market relatively recently, and this high-tech fabric of a new generation came to us from abroad: it was created using American technologies. Today, the material has become quite popular among Russians, and for those who still have doubts, we will tell in the article what kind of fabric it is, in what areas it is used and how it differs from other materials.

What is this fabric?

Polycotton belongs to the innovative high-tech materials of the new generation. It is a blended composition of natural cotton fibers and artificial polyester. When buying polycotton products, pay attention to the information that goes to the description of the product: the percentage of cotton and polyester must be indicated there.

It can be like this (respectively, cotton - polyester):

- 65% up to 35%;

- 50 to 50%;

- 35% to 65%;

- 15% to 85%.

At the same time, keep in mind that the lower the content of natural fibers, that is, cotton, the cheaper the polycotton product will be, and, accordingly, the lower the quality.

Manufacturers of Pakistan, America, Turkey, China, Russia offer consumers a different ratio of polycotton in terms of price and quality - it all depends on the composition.

What does matter take from cotton:

- porosity, that is, the air permeability of the fabric depends on the amount of cotton in the composition;

- hypoallergenic;

- softness and naturalness.

What Polycotton gets from synthetic fibers:

- strength;

- homogeneous structure (fibers do not get confused, fabric does not deform);

- lack of crumpled lines;

- stain-resistant base.

In the absence of available information, the ratio of cotton to synthetics in polycotton can be determined as follows:

- take a piece of cloth and set it on fire;

- if the composition melts and drips, then there is quite a lot of polyester in it, while the flame is blue-green - this is how the film burns;

- if the material burns in the usual way, does not melt, and the flames are yellow, then at least half of the composition is made up of natural fibers.

Polycotton is of several types.

- White. This bleached linen with an even texture (no weaving patterns) is mainly used in hotels and resorts.

- Colored: patterned and solid color. Applicable in the process of sewing sheets, duvet covers and bedding sets in general.

- Quilted. Covers for pillows, blankets, mattress covers, even car covers are sewn from this material. It is a good base for woolen stuffing or synthetic winterizer mass.

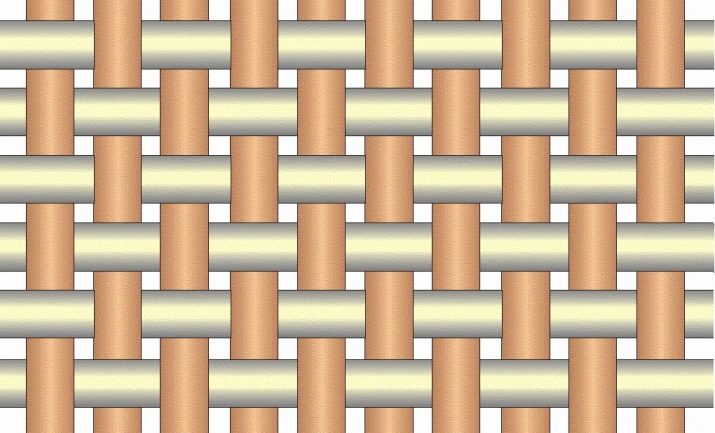

When weaving polycotton fabric, the following methods are used.

- Linen (according to the principle of making chintz, calico, cambric). The result of this weave is a two-sided warp with a smooth surface on each side.

- Twill weave. Such a base also turns out to be bilateral, but slightly with shine and diagonal ribs. Such fabric is softer than linen, does not wrinkle so much, but the previous method guarantees greater strength.

- Satin. This technology makes it possible to produce fabric of a combined composition, very similar to satin. One side of a polycotton that is woven in this way will even slip and the edges may peel off.

- In the technique of weaving satin-jacquard. Such a polycotton is made only by foreign manufacturers. Having a high density (215 g / square meter), it is used for upholstery.

Why is the type of weaving so important? The properties of the fabric and its further purpose depend on this. For example, for sewing accessories for sleeping and home textiles, a base made by the first method is used. Camouflage is sewn from polycotton twill weave.

If, in addition, a water-repellent layer is applied to the polycotton, the material will not absorb moisture and absorb dust.

Advantages and disadvantages

Like any other fabric, polycotton has advantages and disadvantages. The pluses include the following points.

- Low cost. Even a polycotton with a high cotton content will not cost so much compared to similar fabrics.

- Increased wear resistance. The mixture of cotton and polyester makes the fabric quite strong and durable. Bright colors do not fade over time, the color is quite stable even after long-term use.

- Low crease. This mixed fabric practically does not wrinkle, even the bed linen does not need to be ironed after washing.

- Shape retention. The fabric does not shrink and does not stretch, the matter does not deform just due to the presence of synthetic fibers in the composition.

- Easy maintenance. Polycotton is washed both in automatic mode and by hand, while the fabric is equally well washed and dries quickly. By the way, you don't need to spend a lot of powder on the process.

Now let's mark the minuses of the polycotton.

- Poor breathability. Moreover, the material will “breathe” worse, depending on the amount of synthetics in the composition - the higher this indicator, the more problematic the fabric will be to let air through. Due to the fact that moisture (sweat) during sleep will not be absorbed well, irritation may appear on the body if resting on such bedding.

- The appearance of pellets. This material rolls down, the first pellets can be seen after several washes, and after longer use, a polycotton product may look unaesthetic.

- Electrostatic. The combined composition of cotton and polyester is electrified and is a good "Velcro": hair and pet hair quickly appear on it, other debris and dust adhere.

The best option is to buy a composition with 65% natural fibers and 35% polyester.

A material in which an equal amount of synthetics and cotton is also considered to be of good quality.In such proportions, the fabric is able to provide the required hygienic qualities.

Comparison with other materials

I must say that polycotton appeared on the market recently, but has already managed to compete with other fabrics. By the way, to the touch it is practically indistinguishable from calico - in terms of density and texture, these materials are practically the same.

And yet the blended fabric, in contrast to the 100% natural composition, has a slightly glossy sheen. In this case, polycotton cannot be distinguished from satin, especially since it is made with satin weaving? No, there are still differences from satin: the latter shines somehow more naturally, while the mixed composition has an artificial shine, fabric with synthetics is more rustling.

By touch, you can understand which of the materials contains synthetic fibers: natural fabric is softer and more delicate. But again, the supporters of polycotton give their arguments about which is better: a natural composition or a mixed canvas.

It's not a secret for anyone that natural fabrics (the same coarse calico) shrink and wrinkle strongly, which means that ironing after washing is indispensable. In the modern rhythm of life, there is not much time to spend on additional manipulations.

I want to put on a thing and go, wash and put on again, and so on. Well, the density of polycotton (up to 125 g / m) resembles “gauze” - a comfortable thin fabric. Of course, you need to choose a polycotton with the least amount of synthetics in the composition - then we can talk about worthy competition to other fabrics.

If you take teak and polycotton, then both are made from natural fibers and synthetics. Here it will already depend on the percentage of mixed raw materials. It is much more difficult to compare polycotton and microfiber.

Cotton microfiber is classified as a premium fabric, but most of that sold on the Russian market is still a fleecy, slightly spongy fabric, in which there is more synthetics.

Application

This mixture is primarily used for the manufacture of home textiles. So, from it they sew bedding sets, covers for pillows and blankets. An interesting fact is that 8 out of 10 hotels of different levels and from different countries choose bedding from polycotton.

Such a high level of demand for this fabric is associated with its practicality, economy and ease of use. Polycotton is mainly used for sewing various home textiles.

Casual clothes from this material are rarely made, mainly used in the production of sportswear. But when choosing such a shape, you need to pay attention to the percentage of cotton content in this combined fabric.

It should be quite high in order to provide a good level of hygroscopicity during sports activities and allow the body to "breathe". In order for polycotton products to be comfortable, it is necessary that the fabric at least half consists of natural cotton fibers.

This is especially important for those specimens that will be in direct contact with the body. But a high percentage of synthetics is appropriate for decorative elements, for example, curtains, covers, various bedspreads and more.

This fabric is used to sheathe seats in cars, tables in restaurants, and is often used in the manufacture of overalls in factories. So, working overalls, waterproof jackets, raincoats and caps are developed and sewn from polycotton.

This material is used where it is necessary to highlight such a quality of products as waterproofing, for example, they sew tents for military and tourist recreation. But the main area is still bedding: here the material is used without additional processing.

Care

Polycotton managed to gain popularity among many housewives, for whom he made life much easier. For example, many of them express approving reviews about the bedding sets made from it (like these: “I put it in the wash, took it out, dried it and that's it”).

Nevertheless, there are certain rules for caring for this fabric that must be followed. Let's designate the main ones:

- it is better to wash products made of mixed fabrics turned inside out;

- before throwing them into the automatic machine, you need to fasten all the zippers and buttons;

- it is better to wash with ordinary powder (dry or liquid) without chlorine or bleaching particles;

- when washing, do not heat the water above 40 degrees;

- it is advisable to wash the fabric separately from linen and cotton products;

- if ironing is needed, then carry it out on a temperature-sparing mode (not higher than 170 degrees) or in the positions "synthetics", "silk";

- dry only flat and not under the scorching sun;

- store polycotton products in a ventilated place.

Before the first use, it is recommended to rinse any polycotton product in lukewarm water. If we are talking simply about the fabric that needs to be cut, then it is not necessary to wash: it will not shrink after sewing due to the presence of synthetic fibers in it.

In general, polycotton is not such a whimsical material to care for. Subject to all the rules, this fabric can last a very long time.