Overview of awning fabrics and areas of their use

It is impossible to imagine awnings of street cafes, large vehicles or summer pavilions by the sea without awning fabrics. Today there are several varieties of such materials, each of which has its own distinctive characteristics and nuances of use.

general description

The awning fabric resembles an ordinary canvas, which, due to its unique qualities and strength, can be used as a canopy or as a protective layer in the construction industry. In addition, this material is actively used in transport or in domestic conditions.

In order for the awning fabric to fully fulfill its functions, it must be distinguished by certain qualities.

- Strength. Typically, these fabrics are subject to various mechanical stress, so the fabric must be able to effectively resist them.

- Resistant to weather conditions. Such coatings are often found outdoors, so they must be resistant to atmospheric precipitation and direct sunlight.

- Ability to cope with temperature changes, which is especially important in the winter season.

- Preservation of the form. Even after some time, the fabric should not stretch, since the safety of the entire structure depends on this.

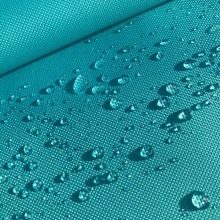

- Waterproof. Both on vehicles and on storage yards or cafes, awning materials must provide reliable protection against moisture.

- Ease, which is important during the installation of awnings, since too much weight forces the creation of more complex structures.The elasticity of the awning materials makes it possible to mount them without the use of special tools.

- The ability to resist the effects of chemicals. If we are talking about industrial facilities, then gasoline or other chemical liquids can get on the canvas. A good material not only does not lose its reliability, but is also quickly cleaned of these products with the help of cleaning agents.

A distinctive feature of awning fabrics is that they are able to maintain their original appearance for a long time, even with active use. Wear resistance is one of the most important factors to look out for when choosing a material like this. In addition, optimal awning fabrics do not contain hazardous components and do not emit them during use, which makes such products as safe as possible for humans and the environment.

Ease of maintenance is explained by the fact that this material does not collect dust and other contaminants, and is also quickly cleaned if necessary. Even at high humidity, awning fabrics are able to maintain their functions, not subject to rotting and mold growth.

And also on the market you can find models that are additionally processed from the effects of harmful microorganisms, which is especially important if awning fabrics are used in the process of arranging a summer cafe.

Manufacturing features

The process of making awning products is quite simple, but responsible. To create an awning, a rectangular piece of canvas is used, which is tucked several times and reinforced with a polymer cord. Only after this is brewing taking place, which ensures the reliability, safety and strength of the entire structure in the future. Small holes are usually made on all sides of the canvas into which metal rings can be inserted. The eyelets are necessary in order to pass the cord through them and secure the fabric to the frame. The frame in most cases is made of wood or metal, since these materials are distinguished by their reliability and durability.

The production of awning fabrics is usually carried out using natural materials or synthetic analogs. In the first case, fabrics are capable of performing their function from 3 to 5 years, but synthetic products can boast of greater durability, which is about 10 years.

Views

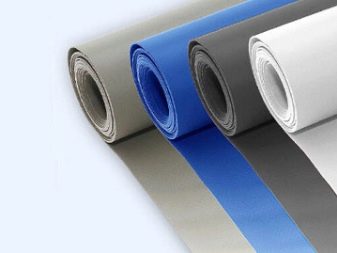

There are several types of awning fabrics on the modern market, each of which has its own unique features and advantages. Such fabric can be transparent, white, black, rubberized, waterproof, hardened, and so on.

Tarpaulin

This is a fairly durable and waterproof material, for which linen or cotton fibers are used. It is possible to achieve high density and strength due to the fact that the material is produced by means of plain weave. Sometimes, in order to provide greater strength, jute yarn can also be used. Tarpaulin can be either ordinary or processed with the help of various impregnations.

They are necessary in order to provide protection against moisture or fire. Such means contribute to the creation of a special film on the surface of the fabric, which prevents mold from forming and microorganisms to multiply. A tarpaulin protected from moisture can be chosen by tourists or hunters.

This material is also actively used on construction sites or open warehouses, where it is necessary to protect items from moisture. As for the refractory options, they are presented in the clothes of firefighters and workers of various factories. In most cases, this fabric has an orange color scheme and is sewn from thick threads.

Tarpaulin can boast of similar properties due to its increased density, which is more than 900 g per square meter. Regardless of its type, tarpaulin is characterized by high mechanical strength, wear resistance, air permeability and reasonable cost.

The main disadvantage of tarpaulin is that it becomes too heavy when it gets wet, so this can negatively affect the process of transporting certain things.

PVC materials

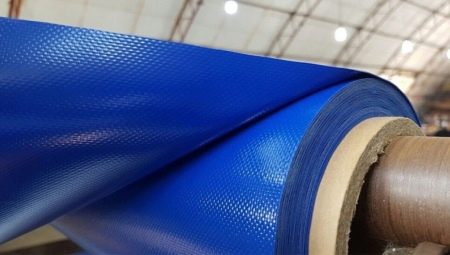

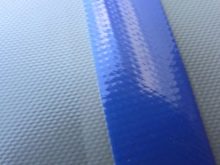

Awning fabrics made of PVC materials are made using artificial fibers, special polymer components. All this allows to achieve optimal density and reliability, which positively affects the process of use. Incredible density and strength are achieved due to the fact that all the fibers are connected to each other at a special angle, resulting in a weave like a basket. The strongest and most durable PVC materials are considered, which are obtained by casting. This method is considered more expensive, but it is reliable and provides maximum material resistance to any external influences.

Lamination is also a popular method of making PVC materials, however, they do not boast high durability. The main advantage of this type of awning fabric is that it is able to withstand the effects of the sun. This result was achieved due to the fact that the product is coated on both sides with a special varnish, which also provides protection from dirt and makes the product more attractive.

Products made of polyvinyl chloride with acrylic impregnation are quite popular on the market today. They are able to withstand the effects of sunlight and also do not accumulate electricity, which provides greater comfort during use. In addition, such fabrics are non-toxic and do not emit any components harmful to humans or the environment.

PVC materials for the production of a canopy are actively used in almost all areas due to many advantages, among which are tear resistance, the ability to repel water, as well as resistance to aggressive components. In addition, this material does not deform due to temperature changes or environmental influences. PVC tarpaulins are in great demand due to the fact that they are easy to repair if necessary.

Regular soldering is sufficient to remove any cuts. In this case, the design will be as strong and attractive as it was originally.

Oxford

The main feature of this waterproof fabric is that it uses a special weave of threads, which makes it possible to achieve strength and elasticity. That is why this type of awning fabric is actively used for sewing sports or tourist clothing. In addition, it can be used to make shoes, bags and other similar accessories.

In most cases, Oxford is done in black or gray. Among the distinctive advantages of this material are its resistance to dirt, protection from wind and the ability to withstand temperature extremes. In addition, this material is quite durable and easy to clean.

Tarpaulin

This tent material is the most modern, it boasts an attractive appearance, reliability, strength and durability. For the production of this material, ordinary polyethylene is used, which is produced in the form of long strips. They are intertwined and then laminated, which ensures such a high quality of the finished product. It should be noted that this type of awning fabric is available only in blue and green colors.

The main advantage of the material is its affordable cost, elasticity and ability to maintain its shape even in the most aggressive environment. In addition, this material is very light, which makes it stand out favorably in comparison with tarpaulin. The unique properties of tarpaulin provide reliable protection against moisture and fire.

Popular manufacturers

There are several well-known manufacturers on the modern market who were able to recommend their products on a positive side. In Russia, the products of the Chinese company Crona and the French brand Sunbrella are popular.

Both manufacturers offer many types of awning fabrics. Chinese options are more affordable, but their quality and durability are inferior to their French counterparts.

Applications

Awning fabrics are actively used to create gazebos on the street, in the process of sewing tourist items or garden furniture. Besides, This material is the basis for the manufacture of tents, car covers, swings or pool covers.

The ability of awning fabrics to withstand weather conditions makes them the optimal solution for creating tents, verandas or awnings.