How to make wooden utensils with your own hands?

Not only the original appearance and pleasant natural aroma of wooden home-made dishes makes them valuable and preferable - it is equally important that they can carry a positive charge of energy, make food tastier and healthier, and in some cases change a person's attitude to many things.

Pros and cons of wooden utensils

Plates, bowls and cups made of wood have a number of advantages, which must be mentioned:

- they are useful for consumption already because they are created from environmentally friendly natural material;

- wood has high mechanical strength and at the same time is light in weight, in addition, such material is able to keep food fresh for a long time;

- the tree itself is distinguished by an aesthetic appearance, and, depending on the breed, has an original natural ornament - such dishes become a real decoration of the table, and it is pleasant to eat from them, but even as a decorative element, such an unusual attribute looks great;

- due to the fact that the wood does not conduct heat, it is impossible to burn yourself against it, and the food remains hot for a long time.

Another advantage of handmade wooden dishes is the ability to create any conceived forms according to the most unusual sketches. At the same time, the material itself is not too expensive, so self-production is considered financially beneficial.

The disadvantages of wooden products are that they have a shorter lifespan compared to glass and polymer fiber dishes; wood can darken and crack if it is not used and stored improperly. In order for a thing to serve as long as possible, it needs competent care and periodic restoration.

Material for making

Basic material requirements for the production of wooden dishes:

- high-quality and plastic wood with high strength characteristics, and such it happens when it is harvested recently, that is, it still retains freshness;

- the tree must be of the first or second grade, there is a minimum number of knots on it;

- an unacceptable marriage is the presence of cracks, chips, rot and blue;

- in the production of dishes for food, only living wood is used, and deadwood preparations are not suitable for this, especially since they can be infected with bark beetles;

- for the craftsman, the large diameter of the wood is also important, since it allows the production of a large number of table accessories.

Soft grades are more flexible and plastic, they cut well during processing, but they are not used due to the lack of sufficient hardness and strength.

Most often, breeds such as elm, oak, birch, maple, mountain ash, juniper, cedar, larch or aspen are used for manufacturing; olive and bamboo are considered suitable materials.

How and from what the ancient Slavs made dishes

In the distant past, our ancestors made different types of dishes - cut, chiseled, chiseled or cooper, which were assembled from rivets and then fastened with hoops. The most popular in Russia was chiseled wooden dishes - this method was used to produce plates, mugs, mortars and glasses, as well as cutlery (pestles, spoons, ladles). In addition, the ancient masters attached considerable importance to the healing and magical properties of certain tree species, which is why they took for their work:

- birch, dishes from which were intended mainly for women, as they could cure infertility;

- nut, which helps to find loyal friends and give life energy in return for wasted energy;

- the olive helped to eliminate migraines, opened up new opportunities;

- oak, symbolizing a strong masculine principle, helped to relieve ailments of the urinary organs and liver;

- girls who wanted to get married faster tried to eat from dishes made from the trunk of an apple tree - it was believed that a female tree would help find the other half.

Perhaps modern craftsmen should also use the methods of the Russians and create products that can not only serve as tableware, but also cure diseases, change a person's fate for the better.

Required tools

If the production of a large batch of wooden utensils is envisaged, it is best to make them on a lathe. However, before that, preparatory work will be needed, including the preparation of material, preferably of high quality, and therefore will require:

- inspect lumber;

- remove excess knots and minor defects;

- to cross-cut timber - divide the transversely cleaned logs into multiple parts, in accordance with the required length of the blanks.

After grinding on a grinding or turning device, the products will need to be varnished (if desired, with a pattern).

But if it is supposed to manufacture a small number of products or a piece copy, when performing manual work, you can get by with a minimum of tools:

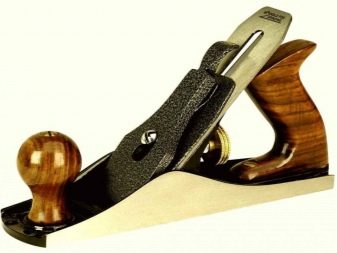

- planer for processing a wooden surface - a plane;

- you will need a jigsaw to cut the workpiece;

- a set of hacksaws of different sizes with different teeth;

- several chisels (cutting hand tools);

- set of cutters required for slotting and planing works;

- emery cloth for sanding wood.

A full-fledged timber, boards are selected as a material, but waste that is suitable in size can also be used. Fewer tools can be used to get the job done if the craftsman is familiar with the manual manufacturing process.

Technology features

For those who are just starting to master the production of wooden tableware, it is better to start with products of a simple shape.

Stages of work.

- First, they make the required workpiece, cutting off the unnecessary part from the lumber, but leaving a margin, since the wood still has to be processed. If this is a plate, then it is better to take a saw cut of a tree of the required diameter.

- Marking of the future thing is applied to the workpiece with a marker.

- After that, the workpiece is fixed with a vise and excess parts are cut off, including recesses and a special relief.

- After marking the lateral contours, proceed to a more subtle process using a chisel or curly incisors.

- It is advisable for inexperienced craftsmen to securely fix the workpiece and work carefully, since any inaccurate movement can lead to the removal of an excess layer.

As a result, the plate takes on its originally conceived shape, but it still needs to be properly sanded with emery stone and paper (the canvas is used for processing curved and internal surfaces).

If a drawing is supposed (ornament, dot painting), then it should be done immediately before soaking and coating with varnish or coloring composition.

The protective layer is necessary because the dishes are intended for food, which means the food can be hot or liquid. This can adversely affect the wood. But the antiseptic agents usually used for this in construction are toxic, so flaxseed oil is used for these purposes. They need to soak the product and wait at least 24 hours until it completely penetrates into its structure. This is done simply - the finished accessory is immersed in boiled oil for a few seconds, twice in a row.

Another coating option is a special food grade varnish that is not exposed to ultraviolet radiation., water, fungal microorganisms and insects. This is a durable product that will help protect wooden utensils from low and high temperatures, the range of its use is from -30 to +60 degrees. If paints such as acrylic or gouache were used for painting, the varnish is applied on top and perfectly preserves the ornament. It is also allowed to cover the tree with a special glue, which is an impregnation of vegetable oil and beeswax.

For information on how to make wooden plates with your own hands, see the video below.