All about sewing machine feet

Sewing machine feet are not just an accessory, but an indispensable structural element that holds and propels the material strictly within the specified boundaries. Their description and purpose, types and applications often raise many questions. Therefore, those who seriously decided to start sewing should know everything about sewing machine feet.

Description and purpose

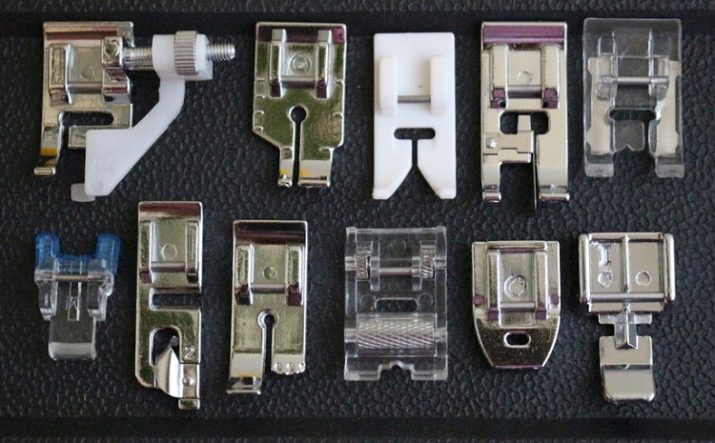

Novice seamstresses usually need the minimum kit for creating a straight or zigzag stitch. More experienced craftswomen may need a clipper walking and hemming foot, overcasting or triple advance. In any case, the wider the range of operations performed by the technique, the more varied the need to purchase additional components for it will be.

Feet for sewing machines are clamping elements with a removable structure, necessary to fix the material in one or more layers on the surface of the bed. Their use allows you to perform various operations: making edging, sewing on a bias tape and buttons, stitching in a zipper, hemming edges. Feet for decorative work make it easier to decorate the material with beads, cords, braid, allow you to make embroidery, appliques. There are special pressing elements for leather and fur, jeans, quilting and patchwork.

Depending on the purpose, the legs are made of metal, plastic, Teflon, and have softening rubber pads. In the construction of the sewing machine, they are fixed on a special rod - a foot holder that moves up and down, fixed with a screw or a special quick-release clamp.

Views

Depending on the operations performed by the sewing machine, there are highly specialized and widespread options. For example, the one-sided (or one-sided) foot is used when sewing on a zipper, and in combination with the triple advance is used when sewing piping or keder. But these operations are needed mainly when creating bags, wallets, accessories, where it is required to form a rigid frame that can keep the shape of the product. In other cases, the presser foot is needed for straight sewing, for sewing on elastic.

There are such varieties.

Standard sewing / zigzag

This is a versatile option, made of metal. The foot is used when sewing in a straight or serrated line, while maintaining the specified pitch.

By default, it is included with all sewing machines.

Walking

It is also called the top feed and is sometimes supplied with the machine in addition to the main foot. The main task of this accessory is to prevent displacement of fabric layers when sewing leather, suede, drape and other thick materials.

In addition, walking feet are needed for quilting blankets and blankets.

For oblique inlay, or "snail"

A special foot into which a prepared bias tape or material for its creation is inserted. Passing through the device, the fabric is edged along the edge with a hem strip. In the course of attaching, the inlay does not move, it lies flat, simultaneously from both sides. The seamstress can only stretch the fabric under the foot.

For lightning

There are options for surface and blind sewing, left and right one-sided. Which one to choose, each master decides on his own. As a rule, a zipper foot is included in the standard equipment of the machine.

For buttons

Use for quick and accurate sewing on buttons with parallel holes. For work, a zigzag stitch of the desired width is used. If there is a darning plate, it is placed down.

If there is no such part, you can simply turn off the lower conveyor.

Undercutting

The hem foot has a different width of the work piece. The fabric is automatically folded in half.

Jersey

Dedicated feet for stretch fabrics with high stretch fabrics prevent the fabric from passing through the hole in the throat plate, keeping the stitch in order. The sole of such a conveyor is equipped with additional rubber pad to prevent sagging of the fabric.

It is recommended to work with tricot feet only at low speeds.

To create pintucks

Presses of this type are used to form decorative pintucks, parallel, and also for sewing on cords. There are special teeth on the conveyor that prevent the line from shifting.

For quilting

Used in needlework - from embroidery and applique to patchwork. Creates seams with different thread spacing and pitch.

For assemblies

With such a conveyor, you do not have to manually gather the product. The gathering frequency is adjusted by changing the stitch width and upper thread tension.

For narrow hems

This foot allows you to create a neat seam along the edge of thin and delicate fabrics, while bending them inward.

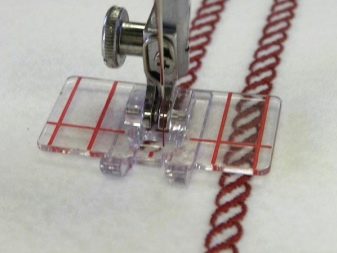

For parallel stitches

This type of feet can be equipped with special guides. Provides for the possibility of uniform formation of two adjacent seams.

Teflon

It is used when working with leather and suede. Prevents creasing and deformation of the material. The seams are smooth, without puffs and gaps.

With limiter

These feet are available in decorative sewing and standard sewing. Provides the creation of a stitch without puckering even on elastic material, allow you to maintain a predetermined indent from the edge when sewing in a straight line. Most often, the stopper feet are used in the industrial production of textiles, when sewing sections, creating blind stitches or detaching. Such accessories are divided into models:

- designed for machines with triple advance;

- with a movable (displaceable) limiter;

- finishing (right and left);

- for vehicles with double advance;

- for patchwork;

- overlock;

- for blind sewing.

Roller

Can replace Teflon when working with leather. In this case, the advancement of the material will occur due to the torque force. It is often used for sewing raincoats, jackets, coats.

Overedge

This foot includes a cutting element that trims the edge before overcasting. When sewing, you need to watch so that the edge of the fabric adheres to the guide as tightly as possible.

Manufacturers overview

The modern market offers a huge number of sewing products. Which manufacturers can you trust when choosing sewing machine feet? Some companies can be distinguished among the leaders of the industry.

- Janome. The Japanese company, one of the leaders in the world market, has existed since 1921; it has had its present name since 1954. It has its own factories in Thailand, Taiwan, and Japan. The firm also owns the American division and the Swiss brand Elna. The company offers a very wide range of presses, is a pioneer in the production of machines for quilting fabrics, embroidery and other operations related to decorative seams and stitches.

A big plus is that Janome has offices all over the world - it's easy to buy the part you need.

- AstraLux. Singapore-based, one of the youngest in the world, manufacturing in Taiwan based on Zeng Hsing Industrial Co. From 2003 to 2013, AstraLux managed to make a colossal leap and from a clear outsider it turned into an almost industry leader, confidently entering the top three world's best brands. The company has a Russian representative office, which makes it possible to guarantee access to all the necessary components among the first.

The AstraLux feet are designed specifically for household use, well adapted to work with different types of materials.

- Brother. A Japanese corporation with its own factories in the USA, Asia, and the EU. It has been operating since 1908, since 1947 it has been represented on the international market. Today it produces not only sewing machines, but also a wide range of other electronic equipment. The model range of legs is quite diverse, in Russia you can buy both original components and universal ones compatible with equipment from other manufacturers.

- Merrylock G. The company specializes in the production of sewing equipment and accessories. Based in Taiwan, it is considered one of the top providers of innovation to the global market. On sale you can find Merrylock G presses for carrying out the most difficult technological operations, working with leather and fabrics, overlock and for covering machines.

- Profi Set. A brand from the budget segment of the market, specializing in the production of feet in sets. Belongs to the Taiwanese company Donwei. The trade mark gained the main popularity among fans of patchwork and quilting.

Manufacturers should be considered separately. "Podolsk" and "Chaika", who manufacture components mainly for their machines, they cannot be adapted for use in equipment from other manufacturers.

Most large Asian and European firms have interchangeable parts.

Selection Tips

When choosing feet for sewing machines, it is worth remembering the main thing: accessories for household models and professional equipment have significant differences. You should not choose the first set that comes across or individual components without specifying this moment. In addition, the presser feet must be compatible with the technique of the particular manufacturer. Many brands prefer to produce components for their cars themselves and do not recommend the use of non-standard parts.

If you want to get sewing equipment with a wide range of default options, you should immediately pay attention to the complete set. The wider it is, the fewer accessories you will have to buy... Conveyors made of Teflon and plastic are most often used for highly specialized applications. They should not be purchased for everyday sewing. It should be borne in mind that accessories for working with decor most often have to be bought separately, it is rather difficult to find a device for working with beads or embroidery in the standard configuration.

How to use?

Many questions arise about the use of sewing machine feet. What recommendations should be followed here? Especially important points should be noted.

- When sewing a bias tape, you can avoid manually overcasting a strip of fabric. It is enough to take the foot with the "snail" device and tuck this material into it. All other operations will be performed automatically. In order for the seam to be even and beautiful, the width of the inlay must correspond to the indicators specified in the instructions for the foot, otherwise the fabric will simply wrinkle inside. There are holes for the unfolded and finished edging - they do not match, you must first figure out what and where to fill.

- The sewing-on feet are for flat items only. This is worth considering. It will not work to sew a button on the leg with their help.

- When sewing in a hidden zipper, you need to start sewing from the top. To correctly fix the teeth of the clasp, it is enough to change the position of the needle.

- It's not just the presser foot that helps you achieve the perfect knit stitch. The best result is obtained by combining it with special needles.

- When sewing thick and thick fabrics, jeans are recommended to set the middle position of the needle, the stitch length close to the maximum (5 mm for household machines). In combination with a special foot, use a No. 100 needle.

- If you need maximum foot lift when sewing in particularly layered areas, but does not sew, shims should be used to eliminate the difference in the height range. It is worth remembering that the conveyor operates normally only in a horizontal position.

How to change?

On older mechanical and electromechanical sewing machines, the feet had to be unscrewed to replace the feet. A screwdriver was included, and the whole operation took a couple of minutes. Modern manufacturers have made this process even easier. You can remove the tab from the stem with one press on the lever on the side opposite to the user. To install a new fixture, you just need to lower the holder into its socket until it clicks. If done correctly, when the lever is lifted, the whole structure will move upward.

You can find out more about which sewing machine feet are really needed.