Sewing machine oil: types, tips for choosing and using

Sewing machines are often used by housewives in everyday affairs, and some craftswomen can sew on them original and unique things. Professional seamstresses and hobbyists alike use different types of sewing machines, but each one needs to be cared for. Whether at home or working in a sewing workshop, you need to use oil that improves the performance of the equipment and prolongs its life. In order to choose the right lubricant and use it on your machine, you must have a certain understanding of the species diversity of oils for this technique and the places of its use.

Purpose of grease

The sewing machine is an excellent assistant in household chores, allowing you to sew, remodel or build what you need for the family. This device plays an even more important role on a production scale, where the company employs a large number of seamstress-mechanics who make sewing products every day. Regardless of what role the machine plays, what device and appearance it has, the main thing is respect for it and timely care.

With frequent sewing, using fabrics of different density and composition, dust, dirt, threads and remnants of matter begin to get into the equipment. If you clean the machine on time, then there will be no problems with its operation. To remove dirt, a special brush with a long and hard bristle is used, which makes it possible to remove hard-to-reach debris.

Cleaning the sewing machine alone will not work to achieve ideal and long-term operation of the device, an even more important measure is the introduction of oil for sewing equipment. Thanks to such additives, you can achieve:

- reducing the load on parts that constantly rub during operation;

- improving the condition of parts that will wear less;

- additional protection of the inside of the equipment from dust and dirt;

- no rust on metal components.

If you apply lubricant to the sewing equipment on time, processing only the necessary areas, then the most important components will be protected, ensuring the reliable operation of all equipment for the longest possible period.

Composition

To know which oil will be the best choice for a particular sewing machine, you need to study its composition.

For this technique, there are two options for oils: synthetic and mineral, for each specific equipment there are certain instructions, which are noted in the instructions.

The lubricant supply can be drip or dry, depending on the type of machine. In large industries for sewing equipment, automated lubrication is used, where the oil is supplied by a computer built into the equipment. Ordinary cars are devoid of such a mechanism, because the hostess must manually select the oil and add it to the appropriate points on the equipment.

Each type of oil has its own structure, composition and method of action, therefore, the selection of raw materials should be taken seriously. Among synthetic oils, the silicone variety is especially popular, which is best used for working with threads, blades, knives, machine parts and assemblies, as well as rubber and plastic elements.

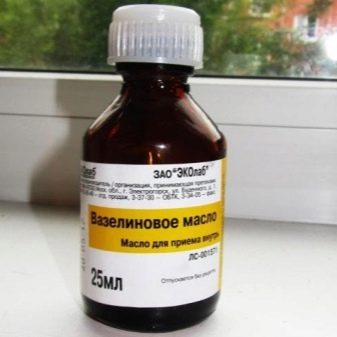

When choosing the most suitable mineral oil, it is worth focusing on vaseline, it is equally well suited for home appliances and industrial use. It can be used to lubricate knives, blades, rubber and plastic elements, parts of knitting machines, in addition, it can help open the zipper on clothing if it is jammed.

Each of the above options is a specialized compound for working with sewing machines, and its cost is quite high., therefore, many housewives recommend using alternative means, processing the machine gun oil. If you have a car in the house, many advise you to pay attention to engine oil. To understand what needs to be added to the technique, and what should be discarded, you need to clearly understand the composition and purpose of each oil option.

Mineral

Mineral engine oil is recovered through a petroleum refining process that results in a mixture of high boiling carbons. To keep your sewing technique in good working order, it is recommended to use petroleum jelly variety.

It is a watery white oil, odorless and tasteless, which is used when the machine needs clean lubrication of the components. Among the advantages of this variety are:

- odorless and tasteless composition;

- has no color;

- safe for health;

- has an antistatic effect;

- after use does not give oily stains;

- there are no solvents in the composition;

- helps to protect the mechanism from corrosion;

- promotes better sliding of parts;

- prevents sticking.

Vaseline oil is used for sewing machines and overlockers, because it does not leave marks on the fabric, and in case of any contamination it is easily washed off. Mineral oils have a moderate cost, therefore they are used more often than analogues.

Synthetic

Synthetic oils are produced through the synthesis of chemical elements, which leads to the exclusion of minerals with solvents from the composition. This option has its advantages, which include:

- the ability to work in temperatures from -40 to +200 degrees;

- good indicators of fluidity of the composition;

- the ability to penetrate into the deepest parts of the mechanisms;

- absence of solvent and mineral components in the composition;

- the ability to use oil when working with parts made of different materials, such as metal, plastic, rubber;

- in contact with fabric or other surface, it is removed thanks to any solvent;

- helps to avoid twisting and sticking of threads, as well as to reduce the number of revolutions of the machine;

- makes it possible to effectively protect equipment from corrosion and oxidative processes.

Silicone oils are very popular and have good characteristics, but their cost significantly exceeds the mineral analogue, therefore the choice of option is often based on the financial component.

Semi-synthetic

Semi-synthetic oils are a cross between the previous two options. They contain components of both petroleum and synthetic oils. The amount of each component may be different depending on the purpose.

You can use this option in the absence of a pure variety of one or another oil, or due to the small amount of mineral and synthetic composition, which alone will not be enough to process the internal parts of sewing equipment.

The main factor in choosing a type of composition will be its quality and the effect that it will have on all the details of the machine.

Manufacturers

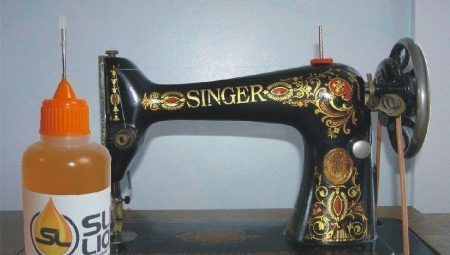

To buy high-quality sewing machine oil, you should navigate not only in the composition, but also in the manufacturers that produce it. It is worth highlighting the most popular and proven brands.

- Mobil - used for garment products, protecting it from corrosion, does not oxidize due to oxidation inhibitors. Available in 1, 5 and 10 liter containers.

- SR-32 oil - Vaseline variety used to ensure good performance of industrial sewing machines. Available in containers of 1 and 5 liters.

- "Cinderella" - a domestic brand of oil for sewing and knitting machines, has an improved formula against oxidation, allows you to increase the operational parameters of equipment. Available in containers of 100 ml.

In addition, you can find oils on sale IGP-18 and I-20A, manufactured for industrial sewing and knitting machines. These products are produced in containers of 5 liters. The cost of each specific product may be different, which is dictated by the country of origin, the composition of the oil, as well as the volume of the container.

What can be replaced

If it is not possible to purchase a specialized lubricant for sewing equipment, and the need for its use is high, then you can try to use what is at hand, replacing the necessary composition with an analogue. Among the most suitable options, it is worth noting:

- replacement of a specialized product with automotive oil;

- the use of a spindle composition;

- you can use M6 engine oil, but not too often due to the higher density of the composition;

- a short-term solution may be the use of vegetable oil, but it is better not to allow it before this option, otherwise the parts inside the machine may stick together and stick.

There are enough options for replacing specialized compounds, but each of them provides only partial help, not being able to process the mechanisms of a sewing machine in the same way as a synthetic or mineral composition does, and often only harm is done to the equipment. Those who are seriously engaged in sewing should not save on care products, otherwise a sudden repair of equipment cannot be avoided.

Oil selection

To find the best quality sewing machine oil, it is necessary to study the available formulations according to the following criteria:

- maximum range of equipment cleaning;

- indicators of the viscosity of the composition;

- the maximum and minimum temperatures at which the full effect of the oil on the sewing machine can be carried out;

- stability of chemical substances of the composition;

- good dirt washout performance;

- the presence of additives.

The cleaner and more transparent the oil, the cleaner the fabric will be after the sewing process, and the internal parts will not stick together even with a long idle time of the tool.

The viscosity index is important in order to understand how strong the film will be, which forms from the introduction of oil into the mechanism. Its optimal indicator should be values in the range of 18-20 mm2 / s. Due to its chemical stability, sewing machine oil does not oxidize and does not lose its basic properties, interacting with metal elements, raw materials and other factors that can act on it from the outside.

Good detergent properties provide maximum cleaning of those areas that are exposed to the greatest friction. Thanks to additives, the quality of the oil can be significantly improved, which will affect the sewing process and the performance of the sewing machine.

To find the oil for a specific machine, it is worth studying the instructions for it. The accompanying documents contain important information about what is best for this equipment and whether it is necessary to lubricate the device. Modern cars have a different structure and materials, therefore it is not always appropriate to use oil for them. To prolong the service life of the equipment and its smooth and high-quality operation, it is important to remove dirt, which becomes the main cause of malfunctions.

With timely cleaning of the machine and the use of lubricants, you can achieve reliable operation of any sewing equipment, regardless of its age and service life.

The choice of oil for lubricating sewing machines is described in the video below.