What does lavsan look like and where is the fabric used?

In the electrical, chemical, textile, automotive, medicine and agriculture industries, they know very well what lavsan looks like and where this fabric, made from fibers with unique properties, is used. Numerous positive properties and features provided the synthetic material with a wide range of applications even before the advent of innovative technologies that made it possible to improve the production process. Synthetic fabric is made by refining petroleum products.

What it is?

Lavsan is a synthetic fiber obtained at chemical enterprises from petroleum products and their processing waste. This name means a rigid-chain polymer, which is obtained due to enhanced intermolecular action. The high temperature to which the polyester granules are subjected leads to their disintegration into their constituent parts, then the threads (fibers) used to make the web are drawn from the melt.

The finished fabric is obtained by different methods, for example, natural fibers (mixed fabric) can be added to it. Polyethylene terephthalate threads are used in pure form. The resulting composition determines the general properties: strength, resistance to rupture, deformation, adverse effects, wear resistance, long-term and problem-free operation, physiological inertness and low crumpling.

The addition of natural fibers means preserving all useful properties and imparting other, equally valuable features: preservation of shape, aesthetic appearance and strength. But at the same time, the properties of a natural thread and improved consumer qualities are acquired.Typical examples are knitted fabric, pique, georgette and taffeta, and a number of other fabrics used in the garment industry for sewing clothes.

Recommendations for lavsan or mixed fabrics are indicated by the manufacturer on the label or in the instructions. But there are general tips: avoid exposure to bleaches, alkalis, high temperatures when ironing.

Materials made with a combination of fibers from different fabrics require additional precautions due to their distinctive features.

Terylene is the official name for a synthetic material adopted in England, in the United States. It is also called dacron, in France - tergalem, in the Soviet Union it was called lavsan.

History of creation

Polyethylene terephthalate (mylar, PET, lavsan) is the most famous representative of polyesters. It is a high molecular weight compound, a thermoplastic. It can change to another state upon application of thermal action. The first studies of properties started in the 30s of the last century in Great Britain, they were carried out by scientists D.R. Winfried and D.T.Dixon, the studies were patented and published in the 40s.

In the Soviet Union, the material was obtained in 1949 in the laboratory of the Academy of Macromolecular Compounds of the Academy of Sciences. The name of the fabric is an abbreviation of the initial letters of the full name of the institution. There is a slight difference in the methods and methods of production used by developers in different countries, so they all issued patents for the production of polyester in accordance with the requirements, each group - for its own technological process with its inherent features.

The stages of transformation, through which the substances obtained from oil are carried, were of different duration, sequence, degree of thermal effect.

The common points were granulation and subsequent melting, the use of extruders to pull the fibers.

In the USSR, lavsan was obtained thanks to E. Aisenstein, who independently developed the original technology for the synthesis of thermoplastic, without studying the research carried out by British scientists a little earlier. Later, in different countries, the thermoplastic received other industrial names: trevira, tetoron, melinex, tekadur and so on, until I came to international polyester.

Some varieties are separated into separate categories, and their names are also almost unified. For example, the abbreviation PET (PET) is used - polyethylene terephthalate.

Basic properties

They are determined by the composition of the material. Blended fabrics acquire the characteristics of natural fibers without losing the beneficial bonuses from the polymer. It is a fully synthetic fabric, just like the blended fibers. It has its merits and demerits. They are always mentioned when characterizing the features of the material, because they determine the scope of application.

Lavsan has a lot of bonuses for a potential consumer:

- excellent wear resistance, durability, long-term and trouble-free operation;

- antibacterial properties and inertness to human tissues (this led to the development of endoprosthetics in medicine);

- color fastness, water resistance, long-term preservation of a presentable appearance even when exposed to adverse weather conditions;

- low crease and water absorption, no side effects from washing (does not stretch and does not shrink).

Synthetic fiber has low hygroscopicity (almost does not absorb water, does not lend itself to coloring with organic active substances). It is quite strict, although some disadvantages are determined by a view aimed at a specific area of application, where they act as advantages. Lavsan is irreplaceable in the manufacture of raincoats, umbrellas, tablecloths and curtains for the bathroom. Mixed fabrics are used for sewing clothes, which have their own advantages, balancing the disadvantages of synthetics.Natural fibers also have unpleasant moments, which are neutralized by the addition of synthetics.

Applications

The area of application depends on the category to which the polymer material belongs: film or cast, made by passing through extruders, in the form of fiber. The use of lavsan in its pure form is in demand:

- in the manufacture of household products for protection from precipitation (umbrellas and raincoats, awnings);

- in the household sphere: bathroom curtains, tablecloths and napkins, raincoats, belts;

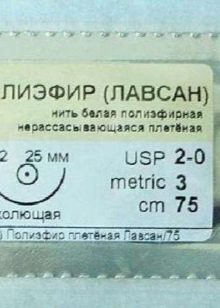

- in medicine: surgical threads and endoprosthetics due to antibacteriality and physiological compatibility with human tissues;

- in agriculture: filter cloth for milk, nets and packaging for received products;

- in the automotive industry: upholstery, drive belts;

- in factories and factories: conveyor belts, ropes, belts, any parts that require strength, lightness and high resistance to repeated permanent influences;

- in the fishing industry (for the manufacture of nets);

- in the food industry and trade in the manufacture of packaging for storage and transportation with antibacterial properties and mechanical strength.

The use of fibers as an integral part of the sewing material allows you to obtain threads and fabrics for sewing with optimized quality. These are decorative and practical materials that are wrinkle-free, resistant to wear, long-lasting staining. Taffeta, satin, georgette are in demand for elegant things. Cotton, linen and wool with polyester are needed to make practical everyday wear with excellent consumer properties. They successfully combine the useful features of synthetics and natural fibers.

Care rules

It is difficult to give a universal recommendation because the precautions indicated are variable. They can be different when it comes to polymeric or blended fabrics. Thermoplastic has the ability to melt under the influence of high temperature, therefore, even if lavsan is in addition, it should not be ironed with an iron with a temperature above + 150 ° C without additional precautions (through a cotton cloth). At the same time, pure lavsan can be boiled and washed in a washing machine, preferably in manual mode and at a temperature of + 50-60 degrees.

There are other subtleties:

- do not use detergents with aggressive ingredients (alkaline salts, chlorine, sodium carbonate);

- dry better in natural conditions;

- it is necessary to wring out the product in a typewriter, without using the maximum revolutions of the drum;

- the properties of lavsan make it easy to remove dirt by hand washing, but the requirement to abandon aggressive compounds remains for soaking;

- straightening the product while drying, you can do without ironing due to its crease resistance.

If we are not talking about fabric, there are precautions in relation to PET, polymer sheets used in construction and agriculture. Manufacturer's requirements are usually indicated in the instructions for use or on the roll labels.

Products made of blended fabric are less whimsical than natural ones, but they can still have drawbacks in the form of vulnerability, accumulation of static electricity, and instability of dyeing. All this clothing manufacturers should indicate on a tag sewn to the seam, or on a tag. When compiling them, generally accepted designations are indicated, so the consumer can avoid unpleasant moments by simply studying the information posted by the manufacturer.