Description of nylon and its scope

Currently, various types of synthetic fabrics are very popular. So, in many areas, nylon is widely used. This fabric has many distinctive features and characteristics. In this article, we will analyze a detailed description of nylon, as well as the areas in which it is used.

History

Capron is a type of fiber that was first obtained during experiments by specialists from Germany. Initially, this material was able to be withdrawn by means of polycaprolactam. In 1938, the first good results were obtained regarding the synthesis, and 5 years later, the technological production of nylon on an industrial scale was established.

It is worth noting that the nylon fiber itself had one very significant drawback - it was extremely rough. Because of this, matter was initially exploited as an auxiliary production component. After some time, Soviet scientists turned to some additions to previously implemented experimental actions. Thus, the polyamide was synthesized.

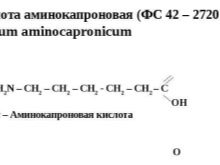

As a result of this major discovery, the production of polyamide fibers began. Then aminocaproic acid was added to it. The Germans created a product that had similar characteristics. This unit was named Perlon. In other countries, it is also called nylon or dederon.

Features of production

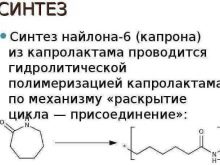

The main production process in the manufacture of nylon is the hydrogenation of phenol. In most cases, the correct isopropylbenzene oxidation formula will be employed. The oxidation process is made possible by two main components, namely benzene and propylene. Petroleum products are used as raw materials in this business. From these products, a component such as caprolactam is produced.

Polycaproamide is obtained from this element. At a further stage, fibers are produced from the resulting product, which make it possible to obtain nylon as a result. Technological operations were primarily focused on continuous work.

Many people are interested in what type of fiber nylon is related to. It should be noted that it is characterized by an exclusively synthetic nature.

During polymerization with the participation of caprolactam, a special gel of high density is formed. As a rule, the gel is a fire hazardous product, therefore, enterprises for the production of nylon fabrics are classified as objects of the highest danger.

The polymerization process is carried out against the background of a temperature value of 270 degrees Celsius. Threads are pressed through a specialized technique from the gel mixture. A little later, these worn-out threads change into fiber form. Before this, the threads are stretched through a special manufacturing process.

Based on the technology, 2 production methods are distinguished. They differ from each other in the direct type of weaving during manufacture.

Properties

If you focus on the appearance of nylon, you will notice that it is a material, the color of which can be transparent or reaching a pale yellowish hue. This product is characterized by a light, discreet shine. It is quite thin but dense fabric.

The material in question is characterized by the following important characteristics:

- sufficient level of strength;

- wear resistance;

- ease.

High-quality nylon material does not stick to dirt. Matter does not deteriorate or deform if it is influenced by water. It is very easy and simple to provide care operations for nylon things - the material is undemanding.

Products that are made from nylon fabric are allowed to be subjected to physical stress, for example, compression. However, if a piece of such fiber is scratched with a sharp object, it can be damaged very easily.

The composition of the matter under consideration is not subject to pathogenic influence from various microorganisms. The constituent fabrics do not absorb moisture into their structure, but during the washing process against the background of excessively high temperature values, they may lose their previous correct shape. The density level of nylon varies. This material is not capable of burning - it only melts, forming a special oily type of substance.

Nylon is an elastic and resilient fiber. It can withstand impressive stretching, after which it always takes its original shape. If you treat such material carefully and carefully, then it is able to serve for a long time. Nylon is not subject to abrasion and rapid wear.

The main disadvantages of the nylon fiber in question should also be noted.

- Such matter is not sufficiently resistant to light influences. Under the aggressive rays of the sun, nylon can quickly burn out, become faded, unattractive.

- Along with many other synthetic materials, nylon is capable of significantly accumulating static electricity. For this reason, products made from this raw material very often stick to the body unpleasantly, until you walk over them with a special antistatic agent.

- Nylon fiber is not hygienic. In conditions of heat and high temperatures, products made from such raw materials should not be worn. Capron does not absorb moisture at all, is not hygroscopic and breathable.Because of this, the human body finds itself in conditions of discomfort.

- The material in question is cold. With the help of nylon, you will not be able to keep warm in cold weather. Warm and cozy things are not made from such fibers. It should be borne in mind that nylon is part of the fabrics from which outerwear is made. Due to this, things are windproof.

- Nylon fiber is not acid resistant.

- Wearing nylon clothes on a naked body causes a lot of inconvenience and discomfort.

Views

Nylon is a popular material that comes in many different types. Each type has its own external and operational qualities. We will find out into which varieties nylon is divided according to the weaving method and color performance.

By weaving method

Currently, there are only 2 main types of nylon fiber weaving:

- linen;

- twill.

With the linen technique, finished products acquire a good strength level, they turn out to be thinner. In the case of twill weave, the thickness turns out to be greater, and the wear resistance increases.

If you fold the threads several times and then twist them, a cord-type thread can form. In addition, the matter under consideration may differ in the level of transparency. The more transparent the thread, the more durable it is. The transparency spectrum varies from absolute colorlessness to a dull yellow shade.

By color

If we consider different variations of nylon, starting from this criterion, then we can distinguish monochromatic and patterned versions of the material.

- Monochrome. From the name of this type, it is clear that the fabric exhibits a single shade. It should be noted that the range of colors of all possible colors of nylon is very rich. There is a choice of pieces from soft and pastel to neon colors.

- Patterned. The material belonging to this category bears another name - flocked. In such a case, the manufacture of nylon turns out to be much more complicated. In the course of special processing, a very attractive and original fabric is formed, which has a pleasant velvety texture. Usually, the type of fabric in question is more expensive than plain.

Application

Today, nylon threads are widely used in textile enterprises. Usually, the range of manufactured garments is expanding due to the production of mixed fabrics. This is achieved by introducing other components to the main material belt. It can be silk or rayon.

Nylon is a modern polymer that is often used in the production of sports goods, as well as products for cars, such as tires. Fabric filters, indispensable in the manufacture, are also made with the use of nylon components.

The matter in question is suitable for the manufacture of a huge number of things that are useful in everyday life. The use of synthetic nylon is reflected in the following popular products:

- different types of cables and nets;

- ropes and curtains;

- tulle;

- consumables used in medicine.

Medical garments, as well as professional uniforms, can also be produced using synthetic fibers due to its composition.

Of course, the fabric in question was most widely used in the production of tights and various accessories. Often, nylon inserts can be found in clothing where a transparent sector is required. These can be T-shirts, T-shirts, or dresses. With nylon inserts, the clothes look very interesting and original.

Care Tips

Despite the fact that synthetic material is unpretentious and widespread, it still needs proper care. Consider a few useful tips regarding care procedures for nylon products.

- Washing such items at high temperatures is not allowed. If the product is going to be washed in a machine, then it is necessary to set the delicate mode. It is recommended not to exceed the temperature of 30 degrees Celsius. However, even at 40 degrees, nylon things will not lose their original properties.

- When washing the products in question, you do not need to use a detergent such as bleach. If necessary, it is better to soak the thing in prepared soapy liquid.

- In the course of washing the items and products in question, it is very important to keep the process of dissolving powder agents under control - they must dissolve completely.

- An item made from synthetic fibers must be rinsed very well. If you do not adhere to this important rule, then the product may lose its previous brightness and saturation.

- It is very important to remember that ironing and wringing nylon products are unacceptable procedures. If there is a special need for this, ironing of the material can be carried out exclusively under the influence of low temperature values.

- If a thing made of nylon fibers is covered with dust accumulations, then it is recommended to use a vacuum cleaner at a moderate power to remove them.

- When wearing nylon items, it is very important to completely exclude their contact with sharp and tenacious objects. If you neglect this simple rule, the product can suffer serious damage, which nothing can be done about it.

- If there are very strong contaminants on the nylon product, then it is not recommended to try to get rid of them on your own. It is better to contact a dry cleaner, where specialists can quickly put things in order.

- Instead of wringing out the nylon product in the washing machine drum, it is recommended to simply hang it over the bathtub. Thus, all excess liquid can drain from it.

- You can squeeze things out of the material in question on your own, but only using a terry towel. In this case, a person must act carefully so as not to spoil the quality of the product.

- When caring for nylon things, it is recommended to use high-quality liquid detergents designed for synthetic fabrics.