What is acetate and where is this fabric used?

Fabric made from acetate fibers is very popular. It boasts high performance, beautiful appearance. Today we will talk about the peculiarities of acetate, analyze its brief description.

What it is?

This material is a fabric that is made on the basis of cellulose through a special treatment. In the manufacture of such fabric, almost 98% of the fiber is used. It is created at a temperature of about +15 degrees.

Acetate has many important properties. It is characterized by increased elasticity, excellent shape retention. This material is practically not exposed to the negative effects of mold, it is easily erased, has dirt-repellent qualities. If necessary, products made from it can be washed by hand or in a washing machine on a delicate cycle. They can dry quite quickly after washing. The smooth surface of the acetate practically does not attract dust and other debris, so it will not get dirty for a long time.

But it should be remembered that such a fabric does not tolerate the effects of high temperatures, and with careless movements, the canvas can easily break. In hot weather, acetate clothing will stick to the body. Under the influence of ultraviolet radiation, it burns out.

The material allows you to create beautiful draperies. It is easy to paint. In specialized stores, you can find fabrics in a wide variety of colors. But at the same time, special pigments are used for coloring. Dyes that are suitable for other fabrics will not be absorbed by the acetate.Acetate fibers have low thermal conductivity, so clothes made from them will be able to retain heat for a long time.

Clothes made from this fabric will not cause allergic reactions, it will not wrinkle while being worn. The smooth, beautiful surface of the material will slightly shine. It is quite resistant to the effects of harmful fungi, microorganisms, so over time, the products will not be damaged by mold, harmful insects.

It should be noted that the tissue is rather weak to tear. To make it more durable and wear-resistant, various synthetic components are added to the composition, due to which it becomes stiff and begins to pass air worse. In addition, the material quickly builds up static electricity.

History

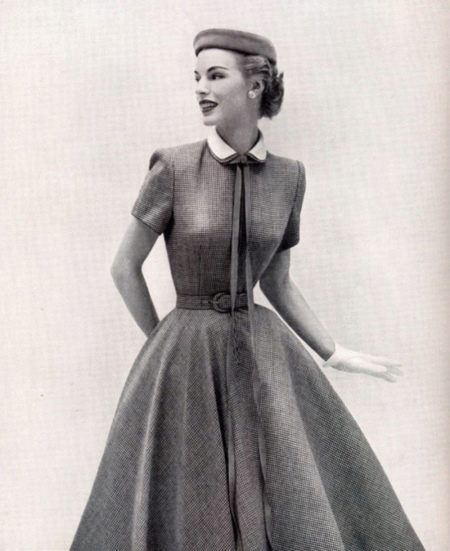

Initially, acetate yarns were obtained in England at the beginning of the 20th century as a result of an experiment. The raw materials were made from cotton fluff and cellulose material. They were processed using acetic acid. The material gained the greatest popularity in the early 50s of the last century. Clothes made from such a base looked pretty attractive and at the same time were inexpensive.

At first, the process of making this fabric was complicated by the fact that there was no dye that was suitable for it. After its creation, acetate began to be used much more often. They used it both as an independent and as a mixed material.

Views

Various types of acetate are currently available. Everything will depend on the composition of the material.

- Wool with acetate. Today, special yarn is produced, which, in addition to woolen fibers, also contains acetate threads. Such material will not roll, shrink. Sometimes yarn is made with acetate fibers and with cotton or mohair.

- Viscose with acetate. This combination will make it possible to obtain fabric with high hygroscopicity and elasticity.

- Acetate with elastane. This fabric is most often used for sewing clothes that must fit exactly on the figure.

- Acetate and silk, cotton. This combination can significantly reduce the cost of the resulting finished material. The resulting base can be used in the manufacture of various garments.

- Acetate and Polyester. The fabric from these components is most often used for the production of lining materials.

We should also mention triacetate fabric. It is also made from cellulose. Raw materials undergo a thorough chemical treatment. This material has a relatively low cost. Triacetate has less strength, low abrasion resistance, medium elasticity. The material is also slightly hygroscopic. But at the same time, the fibers are quite resistant to the effects of various chemical components. The fabric quickly builds up static electricity.

Triacetate is air permeable, the material does not create a greenhouse effect. It keeps its shape well. In its appearance, this fabric is very similar to silk. In addition, the material easily lends itself to various treatments, including soaking, natural drying (in the absence of high temperatures). Clothes made from it will not provoke allergic reactions, skin irritation. She will be pleasant to the body.

Application

Acetate is mainly used in the production of light clothing, including dresses, sundresses, and T-shirts. It is also great for making underwear that can keep its shape perfectly for a long time. The material can be taken to create tablecloths, a variety of decorative items, nightgowns, pajamas, dressing gowns, car covers. Acetate silk is often used for the production of bed linen, curtains, because it drapes perfectly. Also, this material is used when decorating various furniture designs, creating interesting costumes.

Acetate can also be used to make lining for outerwear. Acetate threads easily repel moisture, dry quickly, so it is permissible to use them to create umbrellas, protective curtains for bathrooms, various swimming suits. When mixing acetate fibers and lycra, a rather elastic material is obtained. It is often used to make clothes that fit right on the figure.

Acetates can be found in furniture upholstery. Graduated materials are perfect for interior decoration, creating unusual costumes.

Care rules

In order for acetate products to last as long as possible, you should remember the important rules for caring for them.

- Washing. It is best to wash such products by hand, while the water temperature should be no more than 30 degrees. But it is permissible to send them to the car in delicate mode. Clothes made of acetate threads should not rub too much, so you can simply dip it into a container of water, wrinkle it slightly and squeeze it gently. A small amount of detergent should be used for washing. You shouldn't add bleaches. If you still need whitening, then it is better to prepare a solution with hydrogen peroxide.

- Drying. For products made of acetate threads, it is absolutely impossible to use machine drying. They must be dried on a flat surface, it is also permissible to hang them on hangers. During this procedure, the sun's rays should not fall on the fabric.

- Ironing. Garments made from acetate fibers require little or no ironing. If it is still necessary, then you can use an iron, but you need to iron the material as carefully as possible, and this should be done immediately from the wrong side. The temperature should not exceed 170 degrees. Otherwise, the material will quickly melt and stick to the iron. With proper and careful care, acetate products can last a long time, while remaining bright. It is recommended to iron the fabric through gauze or other thin material.

It should be noted that triacetate is considered to be more resistant to washing and ironing. It can be ironed in the modes for wool and silk. Also, under the influence of hot air, folds can be made on it.