All about self-adhesive fabrics

Self-adhesive fabric is one of the subtle, but significant components in sewing clothes. Without it, it is impossible to create shirts, dresses, fancy dress and much more. The article will talk about self-adhesive fabric for repairing clothes and handicrafts, as well as how to use it.

Peculiarities

Self-adhesive fabric is a material on one side of which a layer of glue is applied. Obviously, such a fabric is used for gluing. As a rule, parts of clothing are glued together during the repair process. And also such self-adhesive makes it possible to give the details of clothing a certain shape.

For example, thanks to this fabric, you can "put" the collar, tighten the cuffs and so on.

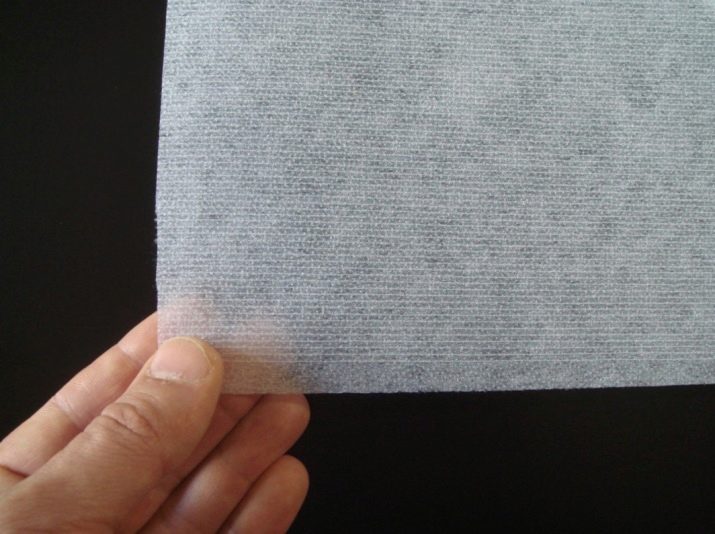

Non-woven, spunbond, dublerin, thermal fabric are used as a basis. They all look like loose matter. But, despite this, such products are quite durable - they hardly break. And also self-adhesive fabric drapes well and easily takes any shape. Among the advantages of the product, it can be noted that thermal fabric tolerates washing well - the glue is not washed off with a gentle mode.

Views

Self-adhesive fabrics can be divided into two main groups.

- Elastic... The base is made of knitted fabrics with a pile and knitted fabric without a pile. Often this is the basis used for needlework. These models are relatively expensive and not readily available.

- Inelastic... They, in turn, are also divided into hard and soft. The fabric is usually made from polyester or cotton. A similar fabric is used to repair clothing. Particularly for repairing fur and leather goods. It is inelastic self-adhesive fabric that is used for collars; some of these products support corsets, give them their characteristic rigidity and strength.

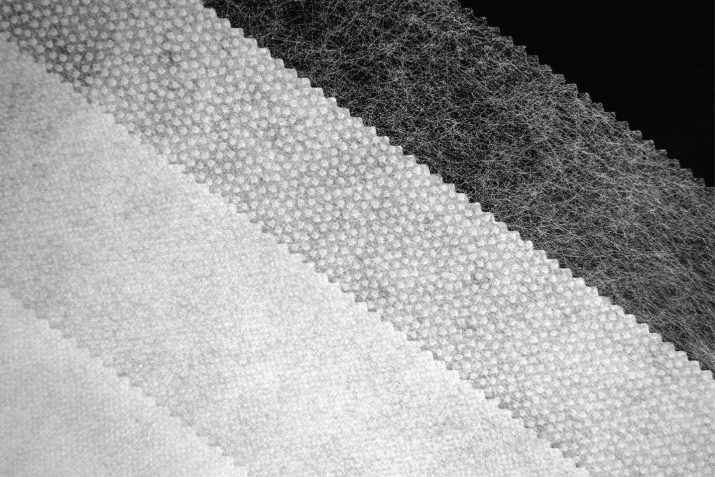

And also thermal fabrics can be divided into several groups according to the glue used: polyester, polyethylene and polyamide... The main difference lies in the melting temperature - the lowest for polyethylene (110 degrees), for the rest it is a couple of tens of degrees higher.

The basis may also differ.

-

Tissue... Obviously, it is a fabric. Used for lapels and splines.

-

Non-woven... Most often seen. It is a compressed fiber.

-

Jersey... It is usually used when sewing business suits and outerwear (for example, coats).

How to use?

It is quite simple to glue such a base fabric. But in order to do this, you need an iron.

- First you need to take a self-adhesive base and wet it... This is best done with a spray bottle. After that, be sure to let it dry.

- Next, you need to find a shared thread at the base and at the fabric on which the product will be glued. The direction of the lobar should be the same for both tissues. You can skip this step if you are using a non-woven material.

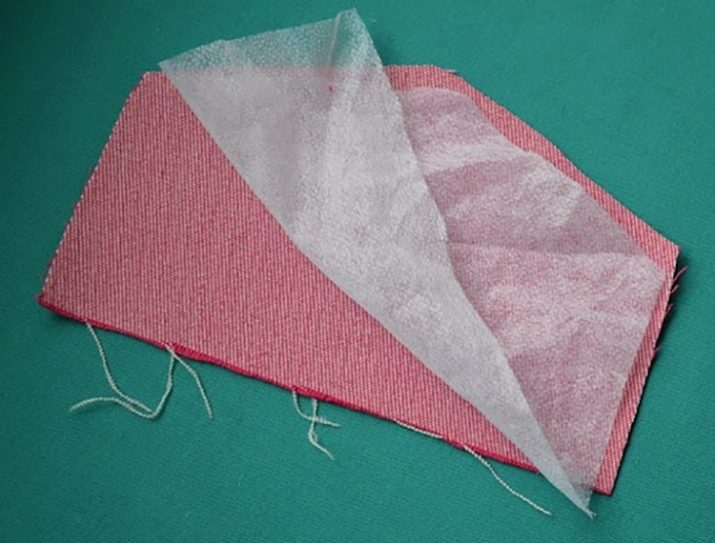

- Self-adhesive material is applied to the material with the rough side... You need to glue only on the wrong side of the material / garment part.

- Afterwards, both fabrics are ironed at 100 degrees.... If the gluing did not occur, then you need to linger for a few seconds on each of the areas. If necessary, you can increase the degree of heating of the iron. This must be done carefully.

You should not glue the thermal fabric to the seams. Otherwise, they can become very hard and cause some inconvenience afterwards.