Features of PAN fabric

Modern textile workers produce more than a wide range of products. In parallel with this, new types of material are constantly being developed, and advanced technologies are being introduced.

PAN can be called one of the interesting types of artificial fabrics. This material has a whole list of features that determine its outstanding performance. The fabric looks and feels somewhat like wool, and at the same time has excellent consumer properties, which, in turn, provides it with more than widespread use.

general description

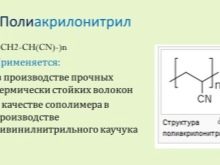

Today, the demand for artificial fabrics, including, for example, velvet, is growing actively and deservedly at a record pace. This is due to the high quality of both the materials themselves and products made from them, as well as their unpretentiousness and cheap production. In the situation with PAN, it is worth starting with the decoding of this abbreviation. We are talking here about polyacrylonitrile, which is a special type of modern polymer fiber used in the production of the described web.

This material is often called faux wool because it feels like:

- dense enough;

- slightly fibrous;

- pleasant;

- warm.

Manufacturers produce canvases, both monochromatic and with a printed ornament. The latter is geometric in the overwhelming majority of cases. Determine the naturalness, as well as the key parameters of any material, will allow the study of the features of the production process. If we consider PAN, then we can say that it is made practically out of thin air. The fact is that when creating matter, natural gas is used - carbon... By the way, this is why the described fabric is called carbon fiber.

According to one version, the first polyacrylonitrile threads were obtained by Edison back in 1880. It is worth recalling that one of his inventions is the incandescent lamp. By the way, it was for the light bulbs that the PAN fiber was created. Much later, interest in these developments appeared in the search for materials for the manufacture of rocket power plants.

It turned out that PAN at that time was the only material that met the requirements in terms of heat resistance, strength and resistance to aggressive action of caustic substances.

The production of carbon fiber involves several stages, which are chemical operations. Initially, oxidation occurs, the purpose of which is to form a carbon structure. Then the substance is heated in a nitrogen or argon atmosphere. The ultimate goal is to increase the carbon concentration to the maximum, that is, 99%. In addition to the PAN fibers and viscose themselves, lignin, phenolic resins, as well as coal and petroleum elements are used as raw materials in the manufacture of various products.

Another important point in production is the dyeing of the material. The fact is that this procedure is performed when the fibers are in a liquid state. It is this factor that determines such important performance characteristics as the absence of a tendency to fade and shed.

On the market you can find fabrics and yarns with 100% polyacrylonitrile content. And also these fibers are additives found in other tissues. Some of the most common types of products are PAN nonwoven yarns and webs.... The threads are continuous and cut, that is, chopped. By the way, PAN is often referred to simply as acrylic. This material, like other types of synthetics, has its undeniable advantages and certain disadvantages. The type of acrylic may vary depending on the thickness of the thread.

The presence of the described fibers in a particular fabric will be indicated by the corresponding Russian or English abbreviation on the label. The percentage of polyacrylonitrile content should also be indicated there.

Advantages and disadvantages

An objective analysis of the key advantages and the most significant disadvantages of polyacrylonitrile will help to make a choice in favor of the described synthetic material. And in fairness, it is worth noting that there are much more advantages here. In this context, the following factors will play a major role.

- The fabric is characterized primarily by softness and lightness.... For example, cardigans made of this type of acrylic can be placed in a tactile row with cashmere products.

- Artificial material practically does not wrinkle, which allows, subject to careful washing and drying, to eliminate the need to iron things. It is thanks to this feature that PAN fabric products tolerate transportation well.

- Considered the material is deservedly called artificial wool... It is successfully used for the production of warm clothes, including outerwear.

- PAN is resistant to aggressive environment... For example, the fabric does not react to contact with many corrosive liquids, including alkalis, acids, gasoline and solvents. In addition, it easily tolerates harsh dry cleaning methods when removing stubborn dirt. Such characteristics significantly expand the scope of the material.

- As noted, fibers are dyed at the stage of liquid state... This makes them immune to ultraviolet radiation, and also allows you to maintain all consumer qualities with long and continuous wear. By the way, as practice shows, things made of polyacrylonitrile do not fade.

- Regardless of the artificial origin of the material, it is absolutely safe for allergy sufferers.

Another important point is that PAN is an extremely unfavorable environment for dust mites and other insects that successfully settle in natural tissues.

Despite all of these undeniable advantages, it is worth paying attention to a number of obvious disadvantages of polyacrylonitrile.

The list of cons here can include the following points.

- Acrylic fabrics prevent the skin from breathing... This feature is recommended to be taken into account by those who suffer from sweating, as well as when wearing things in warm rooms. At the same time, this property will be positive if viewed from the point of view of warm clothing. Such acrylic products are capable of performing the functions of high-quality thermal underwear.

- Particular attention should be paid to the temperature regime when washing products.... The fact is that because of hot water things can stretch and lose their consumer qualities. The situation is similar with ironing.

- Often pellets appear on acrylic items... You can prevent this by avoiding rubbing the fabric against anything. At the same time, the pellets are easily removed from the surface of the material.

- Difficulties may be encountered when removing stains... Due to the structure of the fibers, impurities, especially oily ones, are well absorbed.

- Polyacrylonitrile is characterized in that actively accumulates static electricity.

Application

First of all, it should be noted that the described material often becomes the basis for other types of tissues that are of artificial origin and in many respects identical key characteristics. Their list includes, for example:

- eagle;

- acrylic;

- prelan;

- crelon;

- redon;

- nitron.

Another important point is that polyacrylonitrile can significantly reduce the cost of wool products. It is added to angora, wool and mohair in an amount of 5 to 60%. Predictably, things made from such materials will not be as warm as completely natural ones, but they will cost much less. It is important to note that the introduction of these synthetic fibers into the composition of these fibers also makes it possible to significantly increase the strength of products.

Many people are interested in whether PAN is a textile raw material for the production of clothing or the basis for technical fabrics. The fact is that both statements are true, since we are talking about universality. The main purpose of the described fabric is home textiles.

High-quality, aesthetic and very pleasant to the touch are made of it:

- bedspreads and blankets;

- pillowcases;

- decor elements;

- rugs;

- slippers;

- Stuffed Toys.

From the material in question, modern manufacturers make a large number of varieties and models of curtains and curtains that are fashionable today with various decorative elements in the form of folds and frills. These products are predictably characterized by increased durability and maximum service life, within the framework of which their appearance does not deteriorate. And also important consumer properties can be safely called resistance to direct ultraviolet rays, high-quality light insulation.

From textiles, which contain from 5 to 60% polyacrylonitrile, they make high-quality children's and adult wardrobe items. And we are talking here, among other things, about warm winter clothes. And also PAN is a good raw material for the production of workwear for various purposes.

Another application of acrylic fibers is in the production of artificial fur, which is then used in the manufacture of outerwear and warm shoes, as well as various decorative items.

Polyacrylonitrile is widely and successfully used in the modern advertising industry. This refers to the production of durable banners and awning products. Nowadays, you can find such stretch marks, awnings and advertising structures almost everywhere.And here the key characteristics of the starting material are increased strength and, most importantly, resistance to negative effects of external factors, including sudden changes in weather conditions. As a result, PAN is now quite deservedly one of the best technical materials. In addition to all of the above, considering the fields of application of polyacrylonitrile, it is important to mention the manufacture of:

- fishing and other nets;

- components (fillers) for plastics;

- shipping belts.

Warm and pleasant to the touch, knitwear is made of acrylic yarn.

Care

Taking into account all the listed features and key advantages, it can be concluded that PAN requires minimal maintenance. In principle, the long-term practice of using this fabric confirms the compliance of such a statement with reality. But at the same time it is strongly recommended to follow certain rules and take into account the following points, on which the service life of the material and products from it will directly depend.

- Products are washed at a water temperature of no more than 30 degrees... Both manual and automatic modes are allowed. The material is undemanding to cleaning agents, and therefore both dry powders and liquids can be used.

- Particular attention should be paid to the spinning process. It is not worth twisting and wrinkling the fabric, since it will be enough to squeeze out the bulk of the water with minimal effort.

- After wringing, the item is laid out on a flat surface and given the required shape.... It is in this position that the product should be until completely dry.

- Iron the PAN at a low temperature with the obligatory use of a pad in the form of wet gauze or thin cloth.

- Stubborn stains can be removed with such chemicals.like dichloroethane, acetone and gasoline.

- Garments made of polyacrylonitrile, it is strongly recommended to periodically treat with an antistatic agent, since it is characterized by a tendency to electrify.

In addition to all of the above, it is important to note that stubborn stains in the form of stubborn stains on products should be removed with products that should not contain formalin and phenol. The rest of the PAN fabric is as simple as possible from the point of view of both operation and maintenance. And these factors are among the key competitive advantages.

Subject to basic rules, this material, regardless of its artificial origin, will demonstrate high quality for a long time. A striking proof can be considered a multiple improvement in the characteristics of wool, which contains polyacrylonitrile fibers. This is true for other fabrics containing PAN as well.