All about the width of the fabric

Novice seamstresses and needlewomen sometimes face the choice of which roll to take the cut from. Equally mistaken are those who look only at the price tag, and those who take into account the total area, calculating the cost per square meter of fabric. In each case, the calculation will be unique; it is the width of the canvas that plays an important role in it.

What it is?

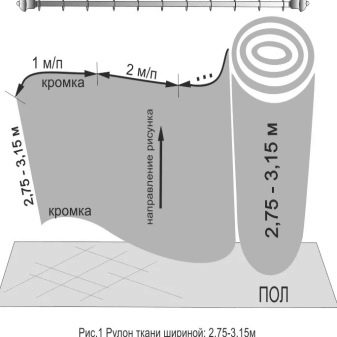

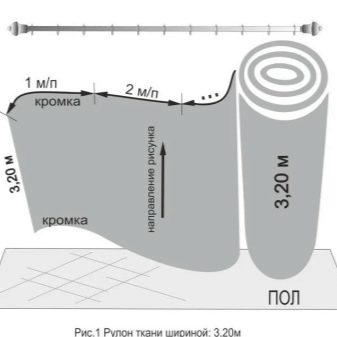

Sewing textbooks unanimously refer to this term as the distance measured in a straight line between the edges of the fabric perpendicular to the longitudinal thread. In this case, the calculation can be carried out taking into account the edge edge and without it. The width allows you to understand what cutting options you have. For example, whether there is enough cut for large-volume jobs with high material consumption, whether there is enough stock for allowances.

Focusing on the transverse size, you can understand how economically the fabric will be consumed. This will be facilitated by the print on the fabric, and taking into account the direction of the thread, and preparing the cutting. But it is the width that sets the initial condition for all calculations. Therefore, it can be considered the second most important indicator after taking measurements.

High-quality fabric will have uniform width on the roll, frequent and significant differences - a sure sign that problems may arise during cutting and wearing. For example, the edges will be stitched or the seams will become oblique after washing. All this is the result of unequal thread tension in the process of forming the panel.

What is the width?

Materials of different quality and purpose may differ in width. This measurement depends on the machine on which the fabric was assembled and finished. In the process of finishing and processing the fabric, shrinkage occurs, so the dimensions may vary. For most materials, processing "eats" 10-15% of the width, drying (drape, fabric on the coat) allows a reduction in width by 30%.

However, for the sake of convenience, there are also standard values: 61, 71, 100 and 133 cm. The extreme values are set as 40 cm and 220 cm:

- linen rolls - 40-50 cm;

- bedding and furniture materials - 160-220 cm;

- dress options - 90-100 cm;

- suit - 142-152 cm;

- cloth for coats - 130-150 cm.

How to measure correctly?

In production, special machines are used that reject and measure deviations, help to see the uneven width of the web. These machines use non-contact measurement with photocells. For control purposes, the width of the web is fixed in several places. The standard provides for checking rolled fabrics at least in 5 places over 50 m in length so that measurements are taken at approximately the same distance from each other. It is impossible to estimate the width along the edge of the roll; the width is taken into account at least at a step of 1.5 m from the cut. If the roll is shorter than 50 m, then it is enough to make 3 control measurements.

In small workshops and home workshops, a special straight ruler made of metal or wood is used. Even a beginner can cope with such a tool. The material is unrolled in one layer on the table, leveled, avoiding folds and tension. Here, to save fabric, greater accuracy is needed, therefore, every 3 meters of length, a transverse measurement is carried out, applying a ruler to the edge edge at a right angle.

This should be done carefully, trying not to move the material when the ruler is displaced. The width in the measurement process is specified to 1 millimeter, and when calculating, it is rounded to 1 cm. The width of the web is calculated as the arithmetic average of such measurements.

If the width difference in the roll exceeds 1 cm, then the smallest value of +1 cm is taken for the calculation. This value is called the actual value. The actual width is of particular importance for cutting out of expensive fabrics, for example, with wool or suiting. Then the actual width is the measurement that was most often encountered during the measurement.

Such manipulations are needed not only for the love of precision. This is an opportunity to check the condition of the canvas, to identify defects before the start of cutting. Knowing the exact width of the fabric, it will be easier to calculate the consumption and think over cutting economically and correctly, observing the direction of the longitudinal threads and weft. Indeed, it is in such a competent cutting that one of the main secrets of straight lines lies.