All about thermal printing on fabric

The relevance of thermal printing on fabrics is due to the budget cost, quality, and aesthetics. In the article we will tell you what it is, what it is, how it is done.

general description

Thermal printing on fabric involves applying a pattern to the material. The execution technique may be different. A common feature is the use of high temperature transfer.

The print can be transferred to natural or artificial substrates. The pigment is securely fixed on any material or finished product. It can be clothes, souvenirs, a banner, a flag.

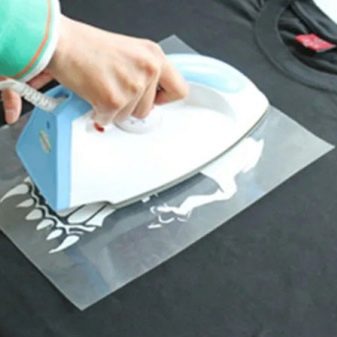

Printing can be indirect and direct. In the first case, the drawing is transferred to a transfer (option with the use of thermal stickers), in the second - directly onto the fabric using a heat press. The technique is performed by thermal transfer and screen printing. In this case, a printing device (inkjet, laser, sublimation type), a heat press, a plastic transfer, and fabric are used.

The printing technology is extremely simple. For maximum image durability, devices with solid waterproof pigments are chosen.

The picture is printed mirrored. The fabric must be completely dry to avoid water evaporation. The type of transfer is hot and cold.

In the first method, the picture is separated from the substrate after heating. Due to the fact that some of the paint remains on the paper, the layer is thin but unsaturated. This is bad for transferring print to dark fabrics.

With cold peeling, the picture is peeled off only after complete cooling. The paint is completely transferred from the substrate to the material. The image is bright, glossy. The pattern overlaps the dark tones of the textiles.However, it is more dense and rigid.

Views

Thermal printing can be classified according to different criteria. According to the type of pigments used, it can be monochromatic and multi-colored.

- One-color is performed with direct and flexiprinting.

- Multicolor assumes layer-by-layer application of a pattern of individual colors.

Direct printing implies fast transfer of the design. However, such products require the most gentle washing in the future.

By the type of application, thermal printing can be sublimation, silk-screen printing, thermal transfer. Each type of technique has its own nuances.

In sublimation printing, a printer is used to print pictures on sublimation paper. Then the image is transferred to the fabric. The method is designed for fabrics with a predominance of artificial fibers.

Thermal transfer silk-screen printing uses the principle of silk-screen printing using special paper for printing a pattern. This technology requires expensive prepress preparation. Along with this, with this type of printing, fonts and small details are not always accurately displayed. In addition, the technique is limited to the set of tones used.

Thermal transfer printing is performed using flex-film made of polymer compounds. The technique is universal, after transferring the picture to film, the drawing is cut out on a plotter and transferred to the fabric using a press.

The latter technique is used for printing one- and two-color images. It is high quality and extremely fast. Allows you to transfer various textures and even glare to fabrics.

Allows transferring the image to an uneven surface. With careful care of things, the images are durable, optimally resistant to deformation and retain their original brightness for a long time.

Prints can be applied using stencils. At the same time, the maximum color rendering, abrasion resistance and gradual fading are observed.

Screen printing allows decorating a picture with sparkles, textures, and glow. The sizes of the images vary, the transfer speed is quite fast.

The disadvantage of this technology is the impossibility of changing the pattern. In addition, screen printing is impossible to achieve photographic precision and the finest contours.

The printed form of the stencil table is a fine mesh, which is pulled over the existing frame and fixed. After that, the light-sensitive layer is spread, then the positively patterned film is placed and exposed.

Equipment and materials

For transferring the image, thermal transfer films of a roll, format type (ribbons) are used. The pattern is cut by means of a cutting plotter.

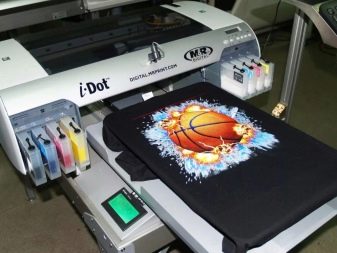

The very process of welding the film to textiles is carried out using a thermal press. When using the digital method, the textile base is impregnated with paint with further heating. When using equipment with direct printing, the pattern is fixed on the fabric due to the high temperature. The paint penetrates into the structure of the fabric, therefore it is visible from both sides.

Press automation varies. The simplest options are manual and semi-automatic, requiring an overlay product. Teflon sheets are used to seal both sides. To decorate light-colored fabrics, special thermal transfer paper with a transparent plastic layer is used. To decorate dark materials - opaque.

Also, a special cut vinyl film is used in production. The films used consist of 2 layers. They are securely attached to the fabric; this procedure takes no more than a few seconds.

The equipment may differ in functionality. There are models for large editions on sale. Other types of devices transfer the print within 30 seconds.

Impressions can be made in 1 or 2 passes. Direct textile printers differ in resolution, the number of printheads.

Other varieties add white ink to the selected color when printing. This increases the brightness of the picture. Also, the transfer of the image can be carousel.

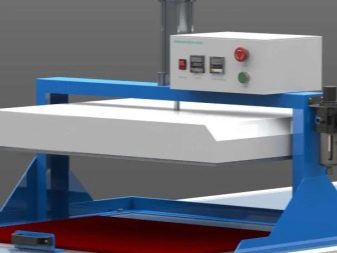

In addition, equipment with a convex surface type is used for thermal printing. It is used for finished products of a convex shape (baseball caps, caps, sleeves of clothes).

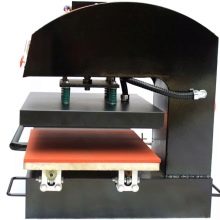

A flat flatbed heat press is used to fix the print. The temperature of the plate, which presses the pattern to the fabric, varies within 220-250 degrees.

The equipment mechanism can be rotary and vertical folding. The options of the first type, when opened, rotate away from the table. The upright-folding counterparts, when opened, rise up.

The equipment differs in the parameters of the heated plate. This makes it easier to transfer the image to products of different sizes. Heat presses differ in power, pressure regulation, type of material.

The equipment is versatile and multifunctional. Consumables are ink, special thermal paper or thermal film, image media.