What is non-woven and where is it used?

Although non-woven is not a fabric, it is considered one of the most sought-after materials for clothing. Most often, a nonwoven fabric is used as a lining for various fabric products.

What it is?

Non-woven is a semi-synthetic non-woven fabric that looks and feels like regular paper... The name, which quickly became a household name, he received from the German brand Vlieseline. The fact that the fabric is non-woven means that there are no transverse and lobar threads on the cuts.

Non-woven fabric can be used not only in the textile industry, but also in construction, medicine, and the production of a number of finishing materials. The cushioning material is often used in sewing clothes, making stuffed animals, and in handicrafts. The material can be used as an alternative to paper, technical and conventional fabrics.

Non-woven fabric most often looks like a soft, translucent and very light fabric. Unpainted material is snow-white or yellowish, but there are also gray, black and even colored versions with patterns. There is an adhesive layer on the surface of the material, which is activated when the fabric is heat treated with a hot iron. Some people compare interlining with an adhesive spider web, but the difference between the two lies in different compositions. In the adhesive web, only glue is present, and in the non-woven, in addition to polyamide, there is also a mixture of cellulose fibers and polyester. The complicated composition makes the second material more versatile and gives it additional properties: for example, the presence of polyester increases the durability of the material.

Nonwoven fabric has higher tear strength than paper, as well as abrasion and fire resistance. Nevertheless thin matter is torn quite often. The material practically does not wrinkle, and hard samples also quickly restore their original shape. Since non-woven fabric perceives any non-aqueous paint, it can be tinted in different shades. The advantage is the low cost of material with a density of 20 to 60 grams per square meter.... Among the shortcomings, it is noted that a continuous adhesive layer makes the fabric heavier, and a point one makes fixation worse.

When creating a material, you first create a pulp from modified cellulose filaments, a liquid carrier and some additives. Further, a long tape is formed from the substance by the method of continuous casting. If necessary, it is subjected to another pressing and glued. The process ends with drying and rolling of rolls 100 meters long and 30 to 150 centimeters wide.

Varieties

There are several variations of non-woven fabric, differing in their properties.

Water soluble

The water-soluble material is used for temporary fixation of fabrics, for example, using the crazy wool technique. If this type of interlining is used when sewing, then the result is more accurate due to the denser and more even arrangement of the threads. The fact that the fabric does not stretch also plays a role.

It is not necessary to remove such a lining, since it is able to dissolve on its own in warm water in just 3-5 minutes.

Formband

Formband is a tape with a standard width of 12 millimeters, with the help of which it is possible to process sections of products: bottom, neck or armholes. To strengthen the shape, a chain seam is planned in the middle.

Volume

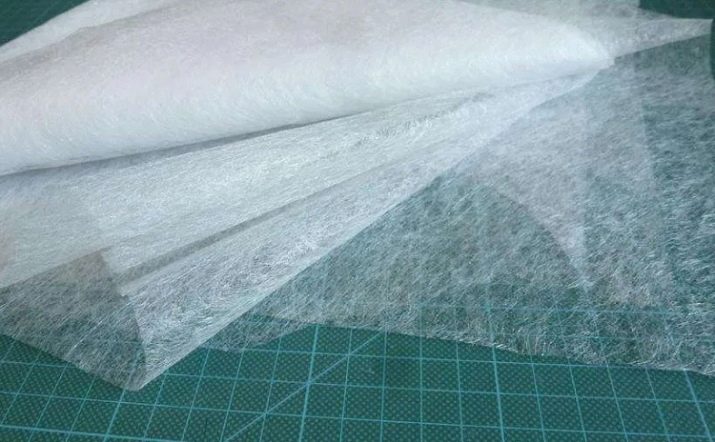

The voluminous non-woven material outwardly resembles a piece of padding polyester: the material is thick, but rather soft. The presence of an adhesive layer and volume makes it possible to use it for the manufacture of quilted products.

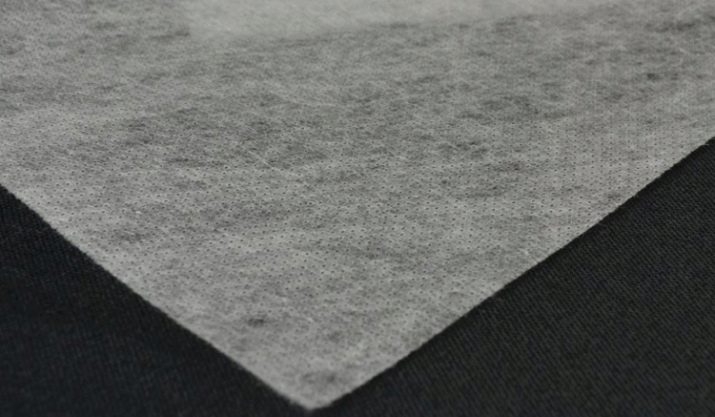

Point

Dot interlining is a subtype of adhesive material, the fixing component of which is distributed over the material in a dotted manner. The lining created in this way turns out to be dense, but rather flexible.

Most often, the variety is used for chiffon, silk and other similar fabrics.

With continuous adhesive base

To obtain a non-woven fabric with a single adhesive base, it is necessary to apply the adhesive evenly over the entire surface during the production phase. The resulting lining has increased rigidity.

Bilateral

Double-sided interlining is also known as interlining. It is equipped with two adhesive surfaces that allow the parts to be fixed to each other. Flizofix can be used to secure folds, create toys and appliques.

Glueless

Glueless interlining does not require adhesive treatment. It, in turn, is subdivided into tear-off and water-soluble. The glueless variety can be removed from the surface of the fabric, and therefore it is often used in needlework. How this is done in the case of a water-soluble non-woven material, as mentioned above, and the tear-off type is simply separated from the base.

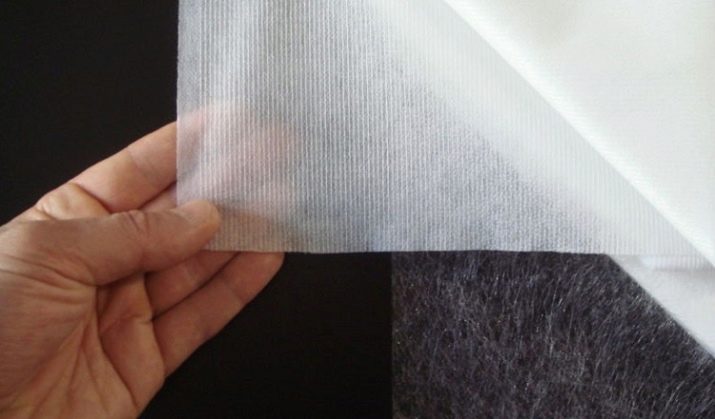

Threaded

Non-woven fabric is thread-stitched, stitched with threads parallel to the edge of the fabric. Such processing of the nonwoven material gives it additional strength, and also allows you to create beautiful folds that do not break at the folds.

How to work with interlining?

It is considered correct to acquire non-woven fabric to match the color of the fabric. If an exact match of shades seems impossible, then for dark products it is better to take gray or black varieties, and for light and colored ones - white. It should also be mentioned that the existing markings indicate which non-woven fabric of what density is best suited for a particular fabric.For example, the thinnest H is intended for silk and wool, the dense E is recommended for leather, suede and substitutes, and the non-boiling F220 is suitable for flax. Stretch G is offered for strengthening pockets and collars.

The fabric can be slightly stretched in the transverse direction, so the material is cut along the line thread and always along the edge. However, the part from the spacer cut should be cut out with the same lobar direction as the piece from the main fabric. Allowances are also required. To successfully glue the material with an iron, you need to warm up the device to the temperature indicated on the package.

Usually, the adhesive layer acquires a viscosity when heated from 110 to 150 degrees, so if no information from the manufacturer is available, it will be enough to set the temperature to 130 degrees.

The non-woven fabric is applied with the adhesive side to the wrong side of the fabric. It is important to carry out this step correctly, as the pad placed on the wrong side will not only be damaged, but also stain the iron. If you can't determine by eye which side is covered with glue, you should run your hand over it - usually both dots and stripes are quite noticeable. In addition, it is necessary to ensure that all parts are dry and that the steam function does not work in the iron. A thin sheet of paper or a protective cotton cloth is placed on top of the backing sheet to prevent staining the iron. The ironer can be either dry or wet, depending on the quality of the non-woven part. The heated device is lowered onto the surface to be treated and left for 10 seconds.

If the non-woven part has a large area, then it is worth warming up individual areas for 3-5 seconds, and then moving it over the entire surface for 8-12 seconds. The glued part is left to cool unfolded for about half an hour. It should also be mentioned that before you start gluing the part, it is recommended to test on an unnecessary piece of base material, and also to check the exposure time and temperature of the iron.

How to remove from fabric?

To remove the non-woven adhesive from the fabric, you first need to steam or iron the product, be sure to use a damp iron... The combination of heat and moisture causes the adhesive to melt, causing the liner to begin to detach from the surface. You can use rubbing alcohol to remove any glue residue. You will need to soak a piece of gauze with the liquid, and then gently remove the sticky substance with smooth movements that do not stretch the fabric. Remains of glue are collected in lumps, which, in turn, are removed by hand.

Another option requires you to first place a blank A4 sheet of white on top of the fabric. The iron is set to the maximum temperature that is not capable of damaging the fabric. The heated device carries out a short pressure, after which the paper immediately rises, "capturing" the adhesive residues. Further, the sheet will need to be moved in such a way that its uncontaminated part appears in each new area. If necessary, the same area can be processed 2-3 times, but with the obligatory replacement of paper.

How to duplicate fabric with non-woven fabric?

Duplication of fabric with non-woven fabric is carried out until the moment the darts are grinded and the cut-off parts are grinded. The specifics of the work carried out by a heated iron were discussed above.

As a rule, fabrics are connected in compliance with the proportional on the non-woven, but in some cases the gasket is cut out obliquely. The contours of the seams on parts requiring an additional layer are applied only after duplication.