Membrane fabric: description and types

One of the most popular materials produced using innovative technologies is membrane tissue, in everyday speech called a membrane. Clothing made of it not only protects from rain, but also allows steam to pass through, guaranteeing maximum comfort to its owner. It is enough for the latter to choose the most suitable type of membrane tissue, paying due attention to the description of the characteristics of the material in question.

What it is?

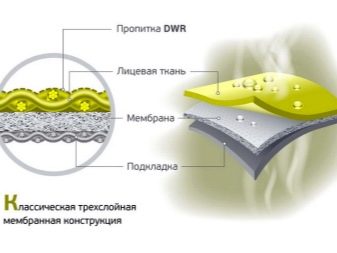

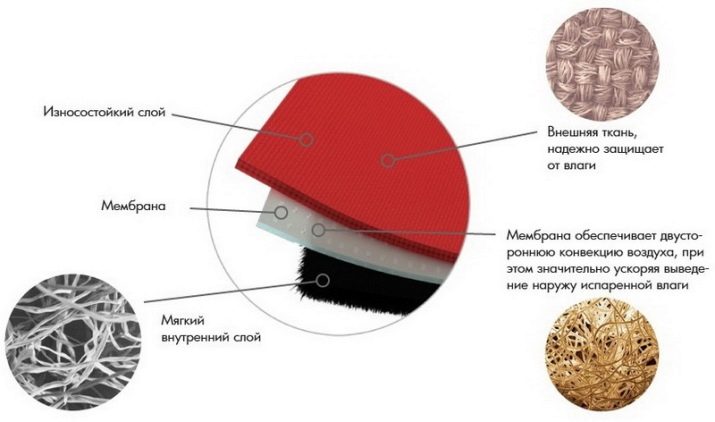

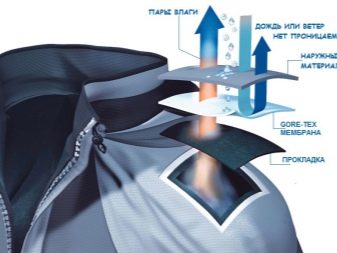

The described fabric is a synthetic material belonging to the multilayer category. Due to their properties, membrane products effectively repel moisture from the outside and at the same time do not prevent the escape of vapors that accumulate in the underwear space. The outer layer of such fabric performs not only an aesthetic, but also a protective function, while the inner one is characterized by softness, which contributes to the comfort of wearing (in some cases, it can be replaced by a lining).

As for the membrane itself, it is located between the layers mentioned above. This component of the fabric is a thin film made of high molecular weight compounds and applied to the base material. In Russia, the described fabric is produced on the basis of GOST 28486-90, the requirements of which it must fully comply with.

Composition

As mentioned earlier, the membrane is an important component of the material in question, but not the only one. As the basis of the latter, synthetics (for example, polyester) are most often used, to which this film is "soldered".

To date, several materials are used for the manufacture of membrane tissues.

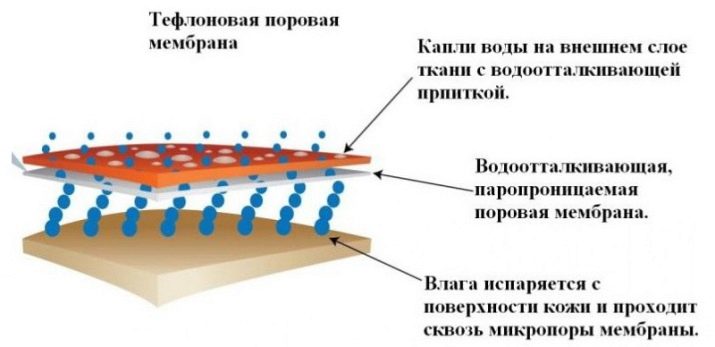

- Teflon. It has microscopic pores that effectively prevent the penetration of external moisture and facilitate the evaporation of internal moisture. The main disadvantage is gradual clogging.

- Polyurethane. The key feature is maximum water resistance. The main drawback of polyurethane products is the relatively slow evaporation of moisture accumulated in the underwear space.

- Polyester. The main advantages of this material are wear resistance and high strength, thanks to which it can be used for many years. In addition, polyester is pleasant to the touch and holds its shape perfectly.

Also, to solve the described problem, cotton is used, primarily remarkable for its ability to retain heat, and bamboo, which can boast of strength and hypoallergenicity.

Combined materials are also worthy of mention: due to the presence of a protective layer, they minimize the likelihood of membrane clogging and extend its life.

Properties

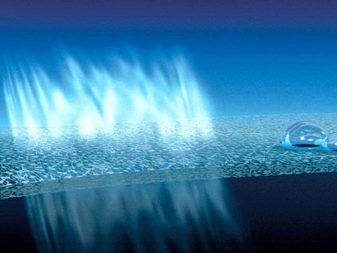

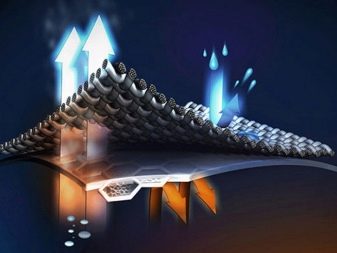

There are two main qualities of membrane fabrics - water resistance and vapor permeability. The first provides protection from external moisture (for example, rain): the higher the value, the longer a person will feel dry. It should be borne in mind that the membrane can repel water for a certain time, after which the latter begins to penetrate into the space underneath. In this, the described fabric differs from polyethylene and rubberized materials, which are completely impervious to water, but also unable to provide air exchange that is optimal for a person.

As for vapor permeability, it determines how "breathable" the membrane is. The higher this value, the more comfortable it will be to wear clothes made of this material during significant physical exertion.

As in the case of water resistance, the vapor permeability of the membrane fabric has its limits, and therefore it may not cope with its duties if the perspiration is excessively intense.

Other advantages of the material in question deserve attention, namely:

- maximum wearing comfort, eliminating stiffness of movements;

- versatility, thanks to which products made of membrane fabric are suitable not only for adults, but also for children;

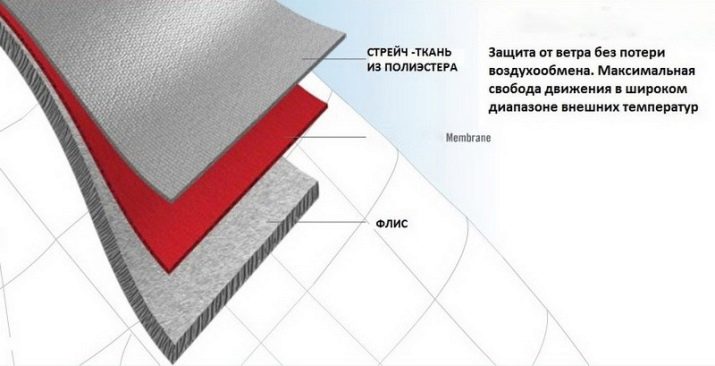

- good protection from strong winds;

- relative ease of removal of contaminants.

Separately, it is worth mentioning the shortcomings, the list of which looks like this:

- high cost of products (provided that they meet the established quality standards);

- the use of artificial components that does not suit the supporters of natural materials;

- not the highest resistance to wear, the specific value of which depends on the category of membrane fabric.

In addition, it is quite difficult to look after the described material, which will be discussed in detail below.

Many people believe that membrane tissue warms well, but this is not the case. By removing excess moisture to the outside, it reduces the risk of body cooling, but at low temperatures there should be two layers of warm clothing under it.

Types and their characteristics

Depending on the characteristics of their structure, membrane sheets are divided into 3 categories.

- Porous. The second name is hydrophobic. Due to the presence of micropores, it ensures effective removal of moist air from the underwear space to the outside. At the same time, this fabric retains water, providing its wearer with a feeling of dryness for a long period of time. A noticeable drawback of the materials in this category is the clogging of the pores, the degree of which depends on the operating conditions of the product.

- Non-porous. This variety, also called hydrophilic, is characterized by the absence of microscopic holes in the membrane layer.It copes with the removal of wet vapors outside due to diffusion, which implies their smooth transportation from the inner layer of the fabric to the outer one. Given the duration of this process, the owner of the product may experience some discomfort (it will seem to him that the clothes are wet).

The effectiveness of using a non-porous cloth is especially reduced when the outside humidity is too high.

- Combined. Such materials organically combine the advantages of the two categories discussed above. Their production involves the use of a hydrophobic membrane on which a relatively thin layer of polyurethane is applied. There is only one drawback for the canvases of the combined category - the high cost.

Also, depending on the design of the membrane tissue, 3 other varieties are distinguished, each of which has its own remarkable characteristics.

Double layer

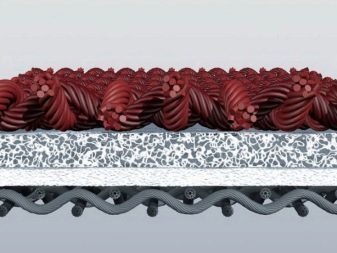

In this case, the membrane has only external protection, and therefore requires the use of an additional lining (usually mesh). The absence of the latter leads to inevitable clogging and mechanical damage to the material, and therefore is unacceptable.

Such products, marked as "2L", boast low weight and good vapor permeability. In addition, two-layer membrane fabrics are used in clothing, the inner surface of which has an insulating layer.

Three-layer

The described variety is marked as "3L" and provides more reliable, two-sided protection of the membrane. Due to this feature, the latter has increased wear resistance, which is its obvious advantage. The material in question looks like a fabric, the seamy side of which is covered with a fine mesh.

Despite its obvious advantages, the three-layer version has one significant drawback - high cost. Given this circumstance, such fabric is used relatively rarely - mainly for the manufacture of professional equipment.

Jersey lining

This type of membrane fabric, also referred to as "2.5L", resembles a two-layer fabric in many ways, but does not involve the use of a standard lining. Instead of the latter, a layer of foamed knitwear is used, which protects the membrane from mechanical stress and clogging.

The main advantages of this material are compactness and lightness. It should be noted that these advantages do not detract from other advantages of the membrane tissue.

How to distinguish from ordinary fabric?

There are several basic ways to distinguish membrane tissue from normal tissue. To buy a product with properties of interest and minimize the likelihood of acquiring a fake, the client just needs to adhere to the following recommendations.

- The simplest solution is to visit stores selling products of proven brands.

- The price of a product made of membrane fabric cannot be low. This is due to the complexity of the manufacture of this material, which involves the use of advanced technologies.

- Often the name of the product in question contains the letter combination "-tex" (for example, "Sympatex" or "Gore-Tex").

- Many popular brands are sold under license. If the seller does not sell counterfeits, he must have all the permits.

In addition, the customer can test the water resistance of the product at home using an ordinary shower. As for the breathability, to determine them, you need a container with hot water, located under the fabric, and glass, which covers the latter.

If the material is a membrane material, it will allow steam to pass through, resulting in fogging of the glass surface.

Where is it applied?

Practice shows that the use of membrane fabrics is justified in a variety of situations that require optimal air exchange and effective protection from high humidity. Such materials are especially appreciated by fans of winter sports, tourism, mountaineering, hunting, fishing and many other hobbies that involve significant physical activity. In addition, membrane fabrics are suitable for the manufacture of children's clothing - jackets, suits and overalls.

It is also worth mentioning the undesirability of everyday use of products made from the material in question. This circumstance is explained by three main reasons - the high cost of such products, the relative complexity of caring for them and the need to wear an additional layer of warm clothing.

Selection rules

Before purchasing clothing made of membrane fabric, the buyer needs to take into account the conditions in which it will be used. Following this recommendation, you can acquire exactly the product that best suits the tasks set for it.

When choosing a suitable product, the buyer needs to pay attention to two key parameters - the previously mentioned water resistance and vapor permeability (for example, 7000/7000). The indicative values of the former are listed below:

- 3000 - insignificant precipitation lasting for a relatively short time;

- 5000-7000 - rain of medium intensity;

- 10000-15000 - heavy and prolonged downpour;

- 20000 - storm (products with such water resistance are intended for yachtsmen and fans of extreme recreation).

To select a product with suitable vapor permeability, the buyer should use the following list:

- 3000 - low level of physical activity (normal walking);

- 5000-7000 - Slow movement on terrain with difficult terrain or jogging;

- 10000-15000 - maximum physical activity (skiing).

There may be some other interpretations, slightly different from the ones given above.

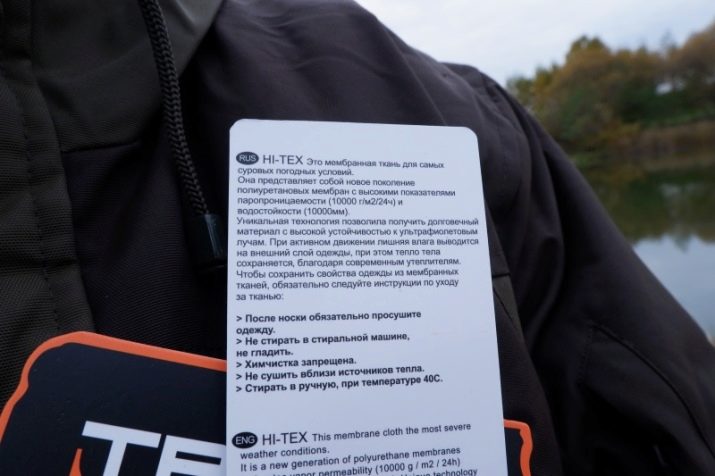

Care advice

In order for clothing made of membrane fabric to delight its owners as long as possible, the latter should pay due attention to caring for it, which provides for a number of important nuances. Washing such products requires certain features.

- Inability to use conventional detergents. This is due to the fact that the washing powder clogs the pores of the membrane, significantly reducing the vapor permeability of the fabric. The same effect is observed after using bleaches and conditioners.

- Detergents containing chlorine act in diametrically opposite ways on membrane materials. They do not clog pores, but enlarge them, increasing vapor permeability and impairing the water resistance of the fabric. Thus, the use of such means will also have to be abandoned.

- In order to preserve the special properties of the membrane material, it must not be machine washed. For the same reason, experts advise against soaking and wringing out such fabrics.

Dry clothes made of membrane materials parallel to the ground surface, having previously straightened, at a temperature of 15-25 ° C. Other significant conditions include good air exchange between the room and the surrounding space, as well as the inadmissibility of direct sunlight on the products.

Do not iron clothing made of membrane fabric. Ignoring this rule can destroy the structure of the material, which is very sensitive to high temperatures.

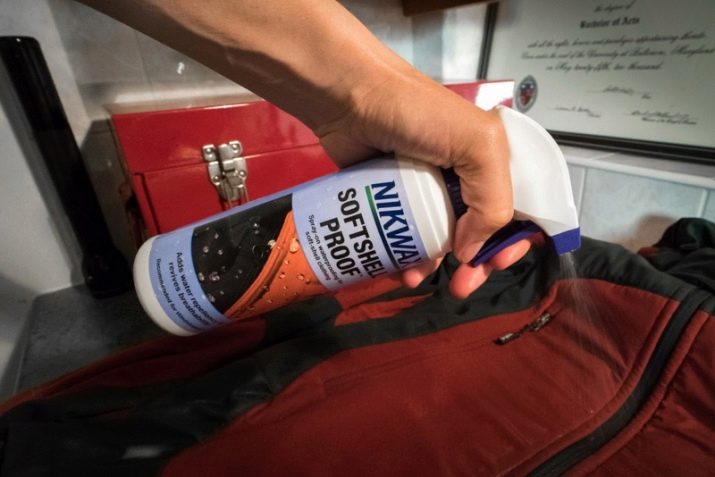

To restore the water resistance of the described fabric, a special impregnation is used - a spray or liquid. This tool forms a film that has several positive qualities at once. In addition to returning water repellency, it:

- does not reduce the vapor permeability of the material;

- increases the resistance of the fabric to dirt;

- reduces the negative effects of ultraviolet radiation.

Processing of products with the use of impregnation must be carried out after washing.It should also be borne in mind that in some cases the fabric may slightly change its original shade.

Storing clothing made of membrane materials requires compliance with two conditions - preliminary straightening and vertical positioning. In addition, it is advisable to cover such products with polyethylene, which prevents dust from entering their pores.

In conclusion, it remains to be noted that an increasing number of consumers give preference to membrane tissues. The advantages of such materials are obvious for every lover of an active lifestyle, which regularly finds its practical confirmation.

For information on how to choose membrane clothing, see the next video.