What are iron-on transfers and how do I attach them to clothing?

In order to decorate or repair any clothing, today there are a number of popular products that will not only cope with their main task, but also be able to transform and improve the usual thing. Thermal stickers belong to the category of similar products, therefore today they are presented in a wide variety.

Peculiarities

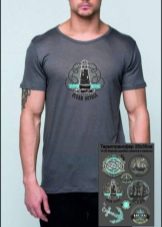

Additional decor on women's, men's and children's clothing is again relevant, in light of which thermal stickers and thermal applications are in demand and are in great demand. Such accessories are actively used by world designers and ordinary needlewomen, fashionistas and young mothers to create a unique image, as well as minor repairs of clothes.

Thermal transfers, or simply stickers and appliques, are, in fact, a picture, the main feature of which is the ability to easily and quickly transfer an image to fabric using available tools, most often an iron. This technology is very popular due to the fact that it does not require significant financial investments, and by sticking the product on clothes, you can avoid the need to purchase a new wardrobe item.

In addition, even the most ordinary monochromatic thing with a pasted applique can become relevant and completely exclusive, transforming beyond recognition.

Iron-on and iron-on applications are accessories whose names reveal the very essence of the product, since in the course of exposure to high temperature and location on the front side of any clothing, the image is transferred or simply glued to the textile.You can buy them at any hardware or clothing store, and a large selection of images makes it possible to choose the right sticker for each occasion, taking into account who owns the thing that requires such a decor, as well as the true purpose of the sticker is only a decorative function or clothing repair.

Today, the most in demand are thermal stickers, where the image is transferred by thermal printing. Such products contain a special film on the base, where a drawing or inscription is printed with ink. This component can be made of polyflex or polyflok. A feature of the first material is the transfer of thinner, but rather dense lines, the latter type allows you to get velvety and soft reliefs.

Before purchasing a thermal sticker, you should clearly define its main function, and also take into account the type of material with which you have to work. Otherwise, even the most high-quality and attractive accessory will not be able to cope with the task, for example, it will sag too much or even spoil the appearance of the wardrobe item. For lightweight fabrics such as silk, a flock patch will not work, this also applies to satin and other summer products. In this case, simpler accessories are used.

But still, the main advantage of stickers is their versatility, since with the correct selection of the combination of the base and the application itself, they can be successfully glued to a down jacket, jacket, trousers or jeans, shorts, blouses, etc. In some cases, needlewomen and designers resort to using thermal stickers for decorating shoes, backpacks, hats and other everyday items.

As professionals advise, stickers are best glued to fabric products., which will be made of dense material. In this case, the risk that the patch will fold into an "accordion" will be minimal. Despite the versatility of the product and the simplicity of operation, the process of fixing thermostickers still has a number of its own peculiarities, which, first of all, relate to the heating temperature of the iron or other device for thermal action on the product. As practice shows, the optimal value is in the range of 120-130 degrees. But when working with a sticker and a heated iron, you should also take into account the capabilities and resistance to heating of the textile base of the decorated product, so as not to spoil it through carelessness.

Despite the fact that thermal stickers and thermal stickers are quite intricate and difficult to call, it is completely unnecessary to purchase them, since such a useful and stylish accessory is quite possible to make at home with your own hands from improvised means.

Varieties

Since the selection of iron-on stickers presented in the accessories and sewing department is quite extensive, there are several signs by which these products can be classified. This primarily concerns the material used for manufacturing. There are the following types of stickers:

- from flex;

- from flock;

- from velvet;

- from atlas;

- from satin.

You can also distinguish two more varieties:

- accessories containing an adhesive base;

- products without it.

Products differ for those that contain reflective elements (such stickers are purchased for workwear, for athletes and children), as well as stickers without phosphorescent applications. Also, stickers can be divided into two main types.

Thermal film

The product is a usual non-volumetric drawing, which was applied to the transfer film. Such products have their own characteristics, first of all, this concerns the impossibility of working with all types of fabrics, since such stickers are intended only for cotton clothing and other products made from these raw materials.Quite often, such products are offered in photo salons for transferring a photo of a person to a T-shirt or creating some kind of commemorative inscription, initials, brand name, etc. The image transfer technology also involves exposure to high temperatures. The main feature of transfer films is their strong attachment to the main fabric, so it will be difficult to remove the sticker over time. If you plan only for a short-term use of an inscription or drawing, then you should purchase a thermal film on a temporary adhesive basis.

Applique on textile backing

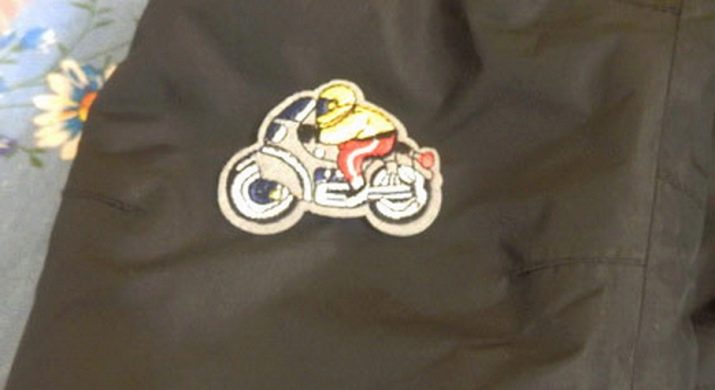

These products are versatile, so they can be worked on all types of fabrics, including delicate and light ones, as well as dense and rough options. Due to this feature, applications are successfully fixed to leather, jeans and synthetics, performing a decorative function and helping to hide existing defects, including holes. Externally, the sticker is not much different from the embroidery. Based on their purpose, thermal stickers can be divided into:

- children's products, which can be performed in the form of images of cartoon characters, animals or toys, bows, flowers, cars, etc .;

- stickers for women's clothes, which can imitate not only hand embroidery, but also lace, contain rhinestones, stones and sequins;

- accessories for men - most often these are logos, emblems of famous sports teams, numbers, as well as inscriptions made in various techniques.

How to glue it correctly?

In order to independently decorate or repair clothes at home, you will need an applique and an iron to work. The technology for manipulating thermal stickers directly depends on the type of product selected for fixing to the tissue.

But before proceeding with gluing, it is necessary to study the information about the product located on the label, since not every fabric will withstand heat, and also conduct a small test at the very edge of the product by touching an iron heated to the required temperature. If the fabric has successfully passed the test and retained its original appearance, you can safely proceed to transfer the selected pattern to the specified area.

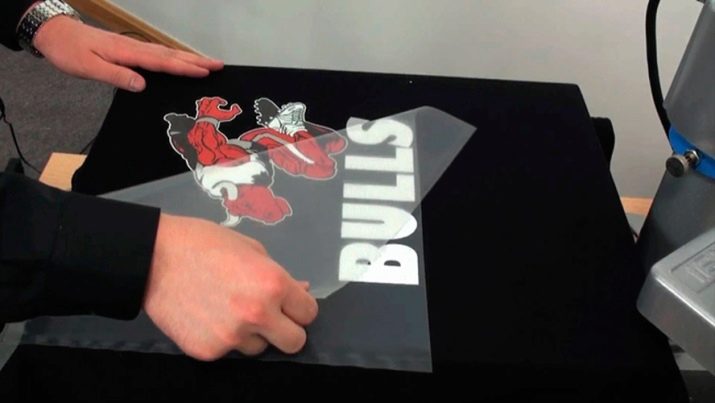

To determine how to proceed with the sticker, a visual examination of the purchased accessory is sufficient. Thermal stickers with film are transferred to the fabric in a mirror image. This must be taken into account before starting work. The specificity of the location of such a sticker on the fabric assumes its placement with the front side to the product. It should be glued following the following step-by-step instructions.

- The base, thing or any other product must be laid out as evenly as possible, without any creases and bends of the fabric on a solid horizontal surface. For these purposes, you can use a table or floor, put a sheet of cardboard under the material in the area of the intended placement of the sticker. A similar measure is necessary in order to exclude the reprinting of the design on the second side of the product, if any.

- Heat the iron to the required temperature in accordance with the type of fabric, first turn off the steam generation mode. Place the applique in the selected place with the image facing the fabric, and with the film facing up.

- Place a regular white sheet on top to protect textiles from damage due to heat exposure, press the sticker to the base with an iron and fix the iron in this position for 10 seconds. Then remove it, let the sticker cool down a little.

- Then remove the backing from the picture with slow and smooth movements. In the case when the image is badly separated from the upper layer and is removed from the fabric along with the film, the procedure must be repeated in the same sequence.

- Having achieved the desired result, the clothes need to be turned out and walked with a heated iron over the place of the transferred image from the inside out.

It is important to select even areas on the product for transferring the image, as this will provide a more reliable fixation. As for areas such as fasteners, seams or loops, it makes no sense to use iron-on stickers there, since the pattern will not be printed or only fragments of it will be transferred. To decorate clothes using appliqué on fabric, you must follow the instructions for working with thermal film. However, when attaching a fabric sticker, it should be borne in mind that the adhesive of such a product is located on the wrong side. Based on this feature of placement, patterns, inscriptions or images should be laid with their front side facing the iron.

As the practice of working with such applications shows, in the process of fixing the product to the clothes, it is best to cover it with tracing paper, a simple piece of fabric or a white sheet of paper, so as not to spoil the fabric itself from contact with the iron. For leather goods, such as jackets, hats or trousers, for the most durable fixation of the sticker before pressing it to the product with an iron, apply a small amount of ordinary universal superglue to the side with the adhesive, and then press the applique with an iron through paper or fabric. ...

Sewing the accessory around the edge is another effective way to keep the image securely in place. Thanks to the additional thread, even during machine washes and active use of the product, the applique will be securely fixed in place. And in order for the additional covering not to be conspicuous, you should choose the color of the threads to match the image. And to highlight the sticker like a patch, you can sew the edge with large stitches in a contrasting color or with thick thread.

In order to repair clothes and mask a hole with a thermal sticker, you need to put a small piece of non-woven fabric or any other material into the gap, and then fix the sticker in the usual way. However, for high-quality work, the substrate and the applique itself must be several centimeters larger than the hole itself.

For information on how to glue a thermal sticker on clothes, see the next video.