Old sewing machines: varieties, brands, use

Our ancestors wore lush, intricate clothing that took a lot of fabric and months of manual labor. The invention of the sewing machine was a breakthrough in tailoring, and since everyone wears clothes, the significance of such a unit can be appreciated as the greatest creation of mankind. Let's talk about old sewing machines: their varieties, brands and uses.

A bit of history

The first attempt to mechanize the work of a tailor was made by T. Saint in 1790, but the stitches on the finished product quickly unravel. B. Timonier improved the apparatus, although it did not in any way resemble the usual "Singer". The first machine with a shuttle and a needle was produced by E. Gough in 1846 in the USA, her stitches were also far from perfect. They became tenacious only after 10 years through the efforts of D. Gibbs, who launched the machine into mass production. And in the 70s of the XIX century. an electric drive was connected to it, thereby bringing the sewing business to an industrial level.

The most famous sewing machine, which existed for more than a century, was created by Isaac Singer in the middle of the 19th century. It was he who invented a device with which the needle made a movement up and down, and not in a circle, like its predecessors. The needles of modern machines work in the same way. His products could be repaired at home, simply by ordering parts, and earlier, after a breakdown, the units were simply thrown away.

The ease of maintenance allowed the Singer sewing machines to be distributed all over the world, and they can still be found in many homes today.

Types and principle of their work

From the moment of opening to the present day, sewing machines have been constantly modernized. Old products, having worked out their age, settled in the collections of antiquity lovers. Thanks to them and the sewing museums, we can find out what our ancestors used to sew their outfits on.

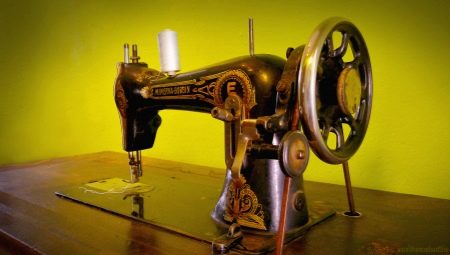

"Singer"

Let's start the description of the types of old cars with the most popular - Singer. Many legends are associated with this equipment, one of them reports on valuable metals from which some of the elements of the machine are made. Perhaps it was this information that raised the demand for "Singer" among antique dealers, but in reality it is not confirmed by anything. This model contains details such as:

- the flywheel is quite massive;

- elongated shuttle;

- manual drive endowed with two gears.

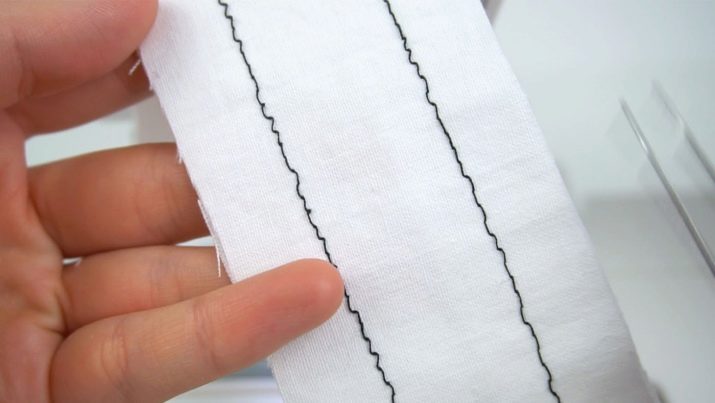

The working moment of the equipment is to create a double loop for gripping during the contact of the loop with the shuttle. "Singer" has a perfect stitching, the unit is simple and straightforward. Many models are still in working order and are ready to “compete” with modern equipment.

"Podolsk PMZ"

The sewing machine was released in the USSR in 1952 at the plant. Kalinin. She gained well-deserved popularity among consumers, she could be found in many Soviet homes. The device and principles of operation of the equipment were as follows:

- the machine produced 1.2 thousand revolutions per minute;

- performed stitches up to 4 mm long;

- had a central bobbin shuttle;

- was equipped with a hand and foot drive.

"Podolsk PMZ" was stably mounted on a flat platform. In some houses, you can still find a similar product today.

"Tula"

Around the same time as the previous model, the Tula sewing machine was released in the USSR. In its production, elements from industrial machines were used, which made it possible for the model to work with greater efficiency. She had an electric drive and was equipped with comfortable foot pedals. At the same time, it was endowed with manual control. The machine has established itself as a progressive and multifunctional device. Unfortunately, no favorable conditions for maintenance were created, so the popularity of the model eventually faded away.

Manufacturers

Each country tried to contribute to the production of sewing equipment. German, Polish names of cars are known. Each brand had its own peculiarity. But most of all, the American corporation distinguished itself with the fantastically successful Singer model.

"Singer"

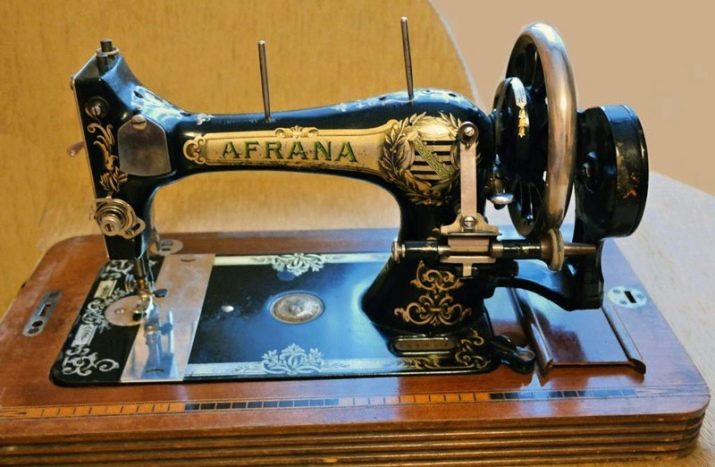

Starting with the famous product "Singer", all subsequent models of various sewing machines were produced in large quantities and were intended for a wide consumer. They had the same type of device and a similar appearance. The reason was the patent that Singer had for his invention. The cars could be produced by the one who acquired the brand's licenses.

For example, Afrana was also licensed by Singer... The shuttle of such a machine was used in early projects of sewing equipment and has long been outdated. Modern fabrics cannot even be tried to sew on such antiques.

Today Afrana is only suitable for retro interior design if it is in good condition.

Borletti

The Italian firm Borletti launched its line of electric sewing machines in 1966. They were extremely rare in the USSR. The product was equipped with a compact folding table, several types of stitches, and a comfortable pedal. The set included a suitcase for storage and transportation. The designer of the model seemed to have looked into the future, and today its appearance resembles modern products.

Buterfly

The Chinese manufacturer Buterfly has released a sewing machine that resembles a Podolsk product in all respects. It differed only in the turn of the bobbin tail, in the Chinese model it is turned to the right. There were no frills in the typewriter, it performed only one line.

"Podolsk Mechanical Plant"

In the 60s of the last century in the USSR at a mechanical plant in Podolsk, a very successful model of the Chaika sewing machine was developed and produced. She had a powerful electric motor, she sewed zigzag and straight stitches, adjusted the stitch size, was endowed with a reverse lever and a device for tensioning the upper thread. Soviet families began to acquire it en masse, since the machine was simple and reliable. Subsequently, the plant began to produce other sewing equipment - "Chaika 132, 143" and about 20 more varieties.

In the early 90s, about 1,800,000 of them were produced, after which production began to decline due to the deplorable economic situation in the country.

Csepel ("Chapel")

Hungarian manufacturer released model Csepel-30, which is a copy of the Podolsk car... The product did not have any special innovations, but at that time there was a demand for similar options.

Operating rules

An instruction or diagram will tell you how to use a sewing machine, but it is difficult to find operating rules for old products. Do not be discouraged, the main thing for sewing is to thread the thread correctly. So, all actions should be performed in order.

- To get a manual typewriter and prepare it for work, you need to open the box in which it is stored. This can be done without a key in case of loss of one, just turn it in the hole with something sharp, since the ingenious lock is rather conditional than protective.

- The equipment is installed on a flat, reliable surface that will not stagger during sewing.

- It is necessary to check the serviceability of the machine, adjust it to a working mood. If the equipment has been in use for many years, and its condition is unknown, adjustment should be done by a professional.

- At the exposed and checked machine, you need to find a needle holder, lift it up until it stops, insert the needle and fix it with a screw. It is necessary to install the needle in accordance with the thickness and density of the fabric. The difference can be seen from the tip and diameter of the steel products. When sewing coarse fabrics, the fine needle may break.

- The pointers on the machine itself will help you to thread the thread correctly. With their help, it becomes clear in which direction the thread should be passed through the eye of the needle.

- The sewing process itself occurs with the help of the translational movement of the needle and the knotty connection of two threads - the upper and lower. To install the lower one, open the groove located under the machine needle and insert the bobbin. Threading is not so difficult, you just turn the handwheel a little, and it will come to the surface by itself. For perfect sewing, the upper and bobbin threads must match in thickness and texture. Better if they are taken from the same reel.

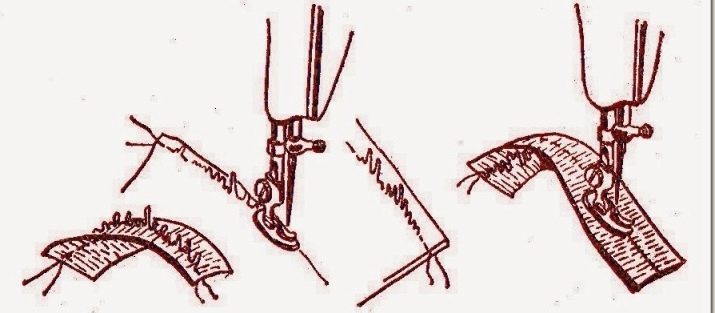

- Next, the fabric is placed under the needle. It is necessary to rotate the handwheel in one direction, backward movements will entangle or break the thread. The rotational movements begin slowly, then the revolutions should be increased. When sewing on an old machine, the fabric will have to be guided by hand, forming an even seam.

- On some machines of past years, it may be possible to switch modes that are responsible for thread tension, sizes and types of stitches.

To make your sewing flawless, we suggest using the following recommendations:

- safety should be observed, do not slip your fingers under the needle while the flywheel is rotating;

- do not try to sew on a hard surface, such as a button, as the needle will break;

- do not rotate the handwheel idle, without a tucked fabric, as this can entangle and break the thread, and blunt the needle;

- during operation, all covers on the machine must be closed, and the levers must be correctly set.

Possible problems

You can count on high-quality sewing, a smooth, beautiful line only if the sewing machine is in full serviceability. If the line is broken, the stitches are skipped, the thread gets tangled - it's time to fix the situation. Let's consider what breakdowns occur and how they can be eliminated.

Upper and lower threads are broken

The reasons for the breakage are different. For the upper thread, they are as follows.

- The thread is not threaded correctly, is sticking. This can be easily fixed by following the instructions.

- The thread thickness is incompatible with the size of the needle, the situation is solved by simply replacing the steel product.

- The threads used are of poor quality, you need to pick up stronger ones.

- Subtle notches can interfere with the progress of the thread. They show up if you observe the thread (where it catches). The defect is removed with a small file. In old-style clippers, cuts can form on the thread tension rod, made by prolonged contact with the threads. They are removed with sandpaper.

Thread breakage reasons (bottom).

- The spring in the bobbin cap changes shape. To eliminate the cause, they take out the cap, unscrew the screw inside it, remove the lock, behind which a long spring is found. You can try to stretch it slightly and tuck it in, trying to return it to its previous state. If this does not work, you will need to purchase a new bobbin case.

- The reason may also be in a bobbin that is not designed for this model of machine. In order not to be mistaken with the choice, you need to take the "native" part as a sample and try to find the same one.

- Poor thread quality often causes both the upper and lower threads to break.

- The thread also breaks from excessive tension.

- A very protruding screw on the bobbin that presses on the spring can become an obstacle. Over time, serrations form on the screw, they can also catch and tear the thread.

- Notches on the bobbin walls can cause a break, in which case it should be changed.

- Deformed edges of the bobbin also pose a risk of thread breakage.

Uneven stitching, thread loops

This defect can be caused by various reasons.

- The thread is not wound evenly on the spool or bobbin. This situation occurs if the thread was wound by hand. To eliminate the drawback, you should rewind it on a specially provided device.

- The stitch can loop if the lower thread is under strong tension and the upper thread is loose, you just need to normalize the situation. By the way, the string will be uneven in the opposite case: the upper thread is taut, and the lower one is loosened, as well as when both threads are tightened or both are loosened.

- Dirt trapped under the bobbin case spring may be the cause, in which case the damaged part should be replaced.

Skip stitches

The reason lies in the discrepancy between the thread, needle and material, everything must be selected correctly, the required thickness. The distance between the needle and the hook tip also needs adjustment.

Tissue advances poorly

The reasons for this trouble are as follows.

- It is necessary to check the sole of the foot; it should press firmly against the fabric. If there is a misalignment, the foot should be corrected.

- The teeth of the rack should be checked, it is possible that they were mistakenly installed in a different mode. By the way, the rail should not be too raised, otherwise the fabric will tighten.

Broken needle

If this happens, immediately pay attention to the following points.

- The needle number does not match the thread and fabric.

- A defective, bent needle is used during sewing.

- The needle is not properly seated in the needle holder.

- If the needle holder is bent, the needle will not hit the center. It can simply break.

Old cars bear the nostalgic stamp of bygone times, they remind us of the life and everyday life of our grandmothers. Those who decide on such an acquisition will be able to feel the atmosphere of antiquity and must be prepared for the fact that the machine may be in working order or require minor repairs, since some models have a surprisingly long service life.

For how to use a manual sewing machine, see below.